tomman58 wrote:

Well here is the deal.

Jayco had 2 guys come out from a mobile mechanic place. They traveled 90 miles to get here in ft Stockton Tx.

They had to tear the entire unit out to fix a loose net that the motor spins to actuate the slide.

Jayco said you should not drive the slides till they click as it is hard on the clutch. The slide just uses a bellville washer that when the motor loads up slips and makes noise. Jayco said mark the floor or get good at stopped the slides before the clutch engages.

I've had jaycos since 1998 and this is news to me and I hope for you also.

Hi,

There are several type of slide drive systems. Do you know which brand slide drive you have?

I have a 2004 with the Lippert rack and pinion drive system. Mine has the Venture brand motor and clutch. On this unit it is suppose to trip the clutch on the way out. On the retract stroke the motor stalls, and you let your finger off.

I have asked both Venture who makes the motor drive and Lippert who make the ACME screw drive and they both stated this "vintage" is suppose to do this.

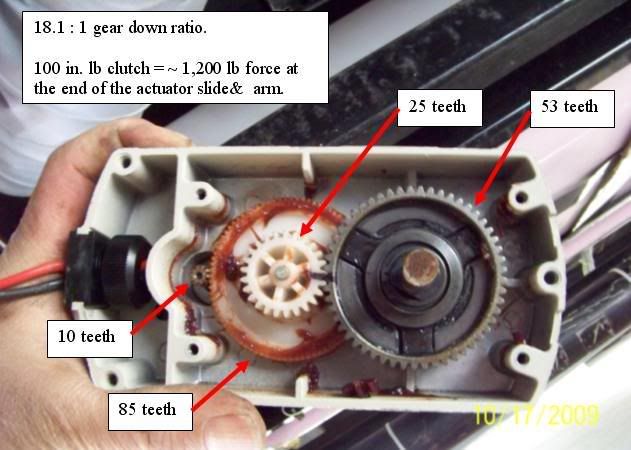

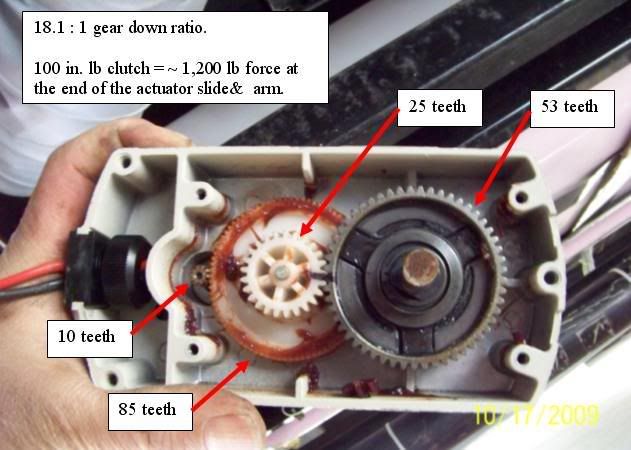

Here are some pics of the motor drive clutch

This is the clutch. The star plate is held engaged by 2 bellville springs.

The star plate

The bellville springs

Here is a progression of how the clutch trips (ratchets)

Star plate engaged in housing pockets

When the drive shaft load reaches the spring tension setting, the star plate starts to come out of the housing pockets

Now it is completely disengaged.

It was mentioned earlier to put the manual crank on and bring the slide in, Pending what type of slide drive you have, I express caution doing this unless you know 100% which direction to turn the crank.

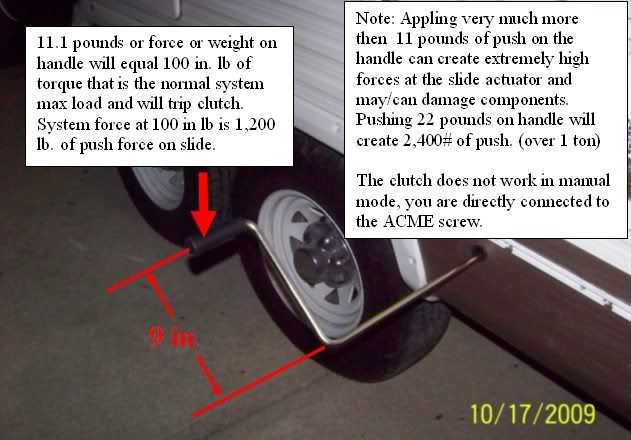

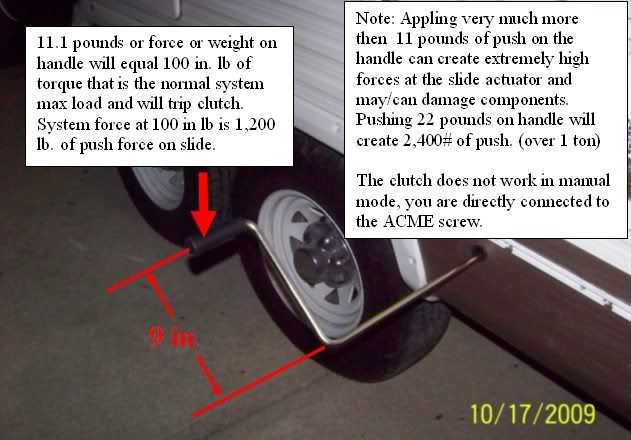

The gear down ratio of a slide drive is immense. After a buddy of mine tore his slide actuator mounts off the camper with the hand crank, H'mm OK I need to figure this out. On this type of slide drive the manual crank turns the ACME screw directly, there is no clutch in this case. The clutch is for the motor drive. So you can put some major "uphm" into that ACME screw and tear the mounts apart.

I measured the torque required to retract my slide. The results where amazing. See here

Torque wrench on slide manual drive

And yes, you are seeing this correct. 25 in. lb. (2.08 ft lb) to is all that is needed to retract the slide.

If I start cracking with very much effort and develop 5 to 10 ft lb, still almost nothing, I can easily create 1,200# of push

Point: Make real sure you are turning the handle the right way and go slow and if nothing is moving, "stop"!

Hope you get your camper fixed up.

John