Forum Discussion

19 Replies

- Aluminum_SidingExplorerMy axle was bent pretty bad. I found a place that would do what is in the you tube vid but it was $500. I purchased a new 3500lb axle for $170. I had to give them the mounting plate specs of the old axle. I replace the axle myself on my drive way in just under 2 hrs. I've had perfect tire wear on the new tires since.

Mike Thompson RV in Fountain Valley CA wanted $2400. Rip Off Artists! They even wanted to weld new hangers on the front which weren't even bent. They also insisted to save labor cost they would have to swap the axle drum to drum including all the break hardware. Save labor??? its four bolts and a king pin nut? The TT was only a year old. Grrrrr! Ok sorry I'll get off my soap box now. :) - JBarcaNomad IIIn today's manufacturing environment it is very achievable from day 1 at the factory to have proper axle and wheel alignment. That however comes with the need, want, skill and most of all, pride to do the job right the 1st time. This does not always happen.

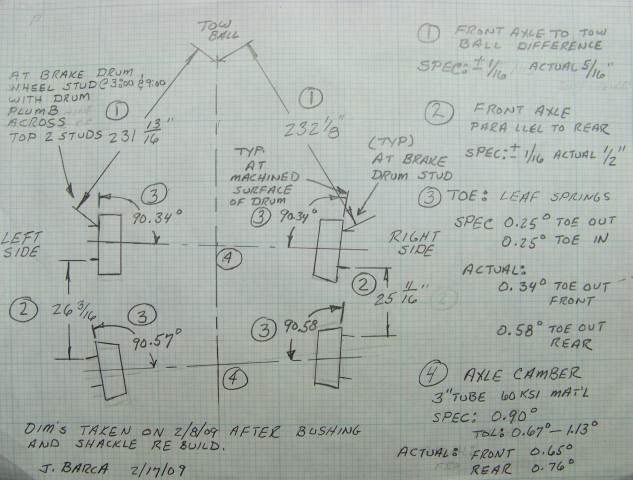

In my case the hangers where welded on wrong and both axles where made wrong. The combo created a situation that created an extreme scrub angle on one tire to the road and another tire on that same side ended up accidentally being located close to perfect alignment so it wore true. The other 2 wheels had a level of wear in between.

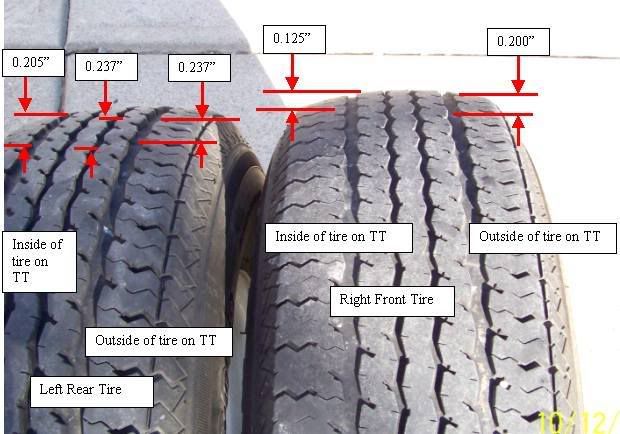

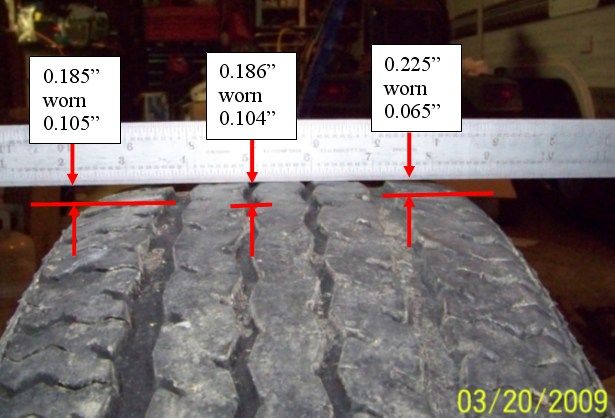

I learned a lot from this unfortunate experience that I took for granted before. If you happen to have a new set or fairly new set of tires and you have access to a depth gage, you can measure the tread depth across the face of the tire. From this info you can determine yourself if they are wearing true or which wheel is showing a problem and by the wear you can back into what may be out. Tires when they are new are close to perfect in tread depth. If the wheel is out of spec it starts a scrub angle to the road and will wear that angle pattern that can be picked up with a depth gage. It only takes 2,500 to 3,000 miles on a new tire and you can tell a lot if you have an issue brewing or life is good. It is hard to tell by eye the early stages of wear unless you are really in tune with what to look for. The depth gage takes the guess work out this.

You can see my saga and correction here:

TT axle alignment & install - Detailed (long lot's of pics)

When I was done I had adjustable axle seats to create proper thrust angle of the front axle within 1/32" and able to make the rear axle parallel to the front within 1/64" in my own yard. That and 2 new axle tubes to fix the wheel toe. Camber was the only thing that was right with my setup. I did upgrade from 5,200# axle tubes to 6,000# for $15 to get a stronger axle tube to help resist agasint bending while in service.

Sad part of this, it was all preventable if the setup was made right. And they do sell vernier adjustable axle seats and have for years. Alko makes them.

So if you want to check for yourself, find a depth gage in 3 decimal places and measure yourself. Even a dial caliper from Harbor Freight can do this.

Here are some excerpts from my post. Measuring thread depth

What new is like inflated

2,500 miles on a new tire after alignment correction

Tire wear on right side of camper

Tire wear on the left side. The real bad one

The one wearing right oddly enough. This axle had extreme toe out however since the front axle was mounted wrong it actually tipped the wheel into running true.

And the spare put in that bad left rear location after ~ 2,500 to 3,000 miles as I was sorting this out. This is how fast out of alignment can show up

And a tire wear map. By plotting the tire wear as it is located on the trailer from the top, you can see the how the wheels/axles are in or out of alignment. If your camber is off, this needs to be taken into consideration too. This method will help to see thrust angle and wheel toe

Hope this helps and good luck

John - mosseaterExplorer IINo offense intended to those who say you can't or shouldn't, but if you have tracking problems or tirewear issues, etc., then it most definately needs to be done. It's not the easy proposition that it is on vehicles, as it normally involves cutting, welding, bending, etc. My problem, and most with tire wear issues, was spring hanger/mount locations. The axles need to be parallel to each other and perpendicular to the direction of travel in order for good tire wear and tracking, and the tolerances are likely tighter than you might imagine. Think in terms of 1/8" or less. For example, the centerline diagonal measurements on my trailer were supposed to be within 1/2" of each other, and weren't. I think you'll find this kind of inaccuracy in Mfg.ing is pretty common. Just that most folks don't travel enough to see it show up as serious tire wear. If you're in doubt, find a reliable shop and get it checked. Mine cost $400 to get right, but life is good now. Shame they couldn't get it right at the factory.

- ExxWhyExplorerI had mine done last summer. The left rear tire wore out the inside of the tread when we went out west the year before. Put less than 1000 miles since the allignment, but I think it's OK now. The trailer had mismatched tires when I bought it, so thinking it's had the issue for a while before I owned it.

They used a similar setup as pictured in the video and it was $125 to have it done. A small truck/trailer shop in Fremont, OH.

If you don't have tire wear issues, I wouldn't bother with having it checked. - goducks10Explorer

myredracer wrote:

goducks10 wrote:

I had to have it done on a Heartland TT with Lippert axles. A specialized shop did it. $190.00 total. They hook up chains and a hydraulic jack and bend the axles back to straight.

Here's how it's donehttp://www.youtube.com/watch?v=pRyTeqYuGBk

Interesting that the guy said that the axles will bend again over time. If they bent that much to start with (3/4" & 7/8" out) and are going to bend again, isn't that a symptom of under-rated axles? Why not just buy new axles in one or two sizes higher rating? I don't think axles are all that expensive and especially if you end up having premature tire wear again. Axles are often too close to the weight they are carrying and there's not much of a margin.

As a matter of fact the guy that did my alignment said my axle material was soft and he put extra camber in. So Depending on who makes the axles or whether they're spec right yes the could just bend again. I knew I wasn't going keep the TT forever so I went the cheaper easier route. - thomasmnileExplorer

goducks10 wrote:

I had to have it done on a Heartland TT with Lippert axles. A specialized shop did it. $190.00 total. They hook up chains and a hydraulic jack and bend the axles back to straight.

Here's how it's donehttp://www.youtube.com/watch?v=pRyTeqYuGBk

Good video, informative. Thanks for posting the link. - OBSPowerstrokeExplorerI had my trailer aligned after installing a wet bushing kit and a new set of Maxxis "D" weight rated tires (a step up from the cheapo Cs that came from the factory)

The alignment wasn't cheap, but the outsides of the OEM tires were bald after only about 5,000 miles. The tire wear was mainly due to the tires being junk and underrated for the trailer, however the shop did have to make some adjustments to get the alignment spot on.

I have put on at least another 5,000 miles since the work, and the tires still look new and show no uneven wear. I'm not sure if it's due to the better tires, wet bushing kit, alignment, or a combination of all three, but I'm happy and figure it was money well spent. - myredracerExplorer II

goducks10 wrote:

I had to have it done on a Heartland TT with Lippert axles. A specialized shop did it. $190.00 total. They hook up chains and a hydraulic jack and bend the axles back to straight.

Here's how it's donehttp://www.youtube.com/watch?v=pRyTeqYuGBk

Interesting that the guy said that the axles will bend again over time. If they bent that much to start with (3/4" & 7/8" out) and are going to bend again, isn't that a symptom of under-rated axles? Why not just buy new axles in one or two sizes higher rating? I don't think axles are all that expensive and especially if you end up having premature tire wear again. Axles are often too close to the weight they are carrying and there's not much of a margin. - myredracerExplorer IIAnother problem that can happen is that the spring hanger brackets can be welded in the wrong location front to back relative to the opposite side. I've read about this happening and having to cut the brackets off and weld them back on where they should be. This should not be overlooked if you're having tire issues.

Plastic bushings in the leaf springs could be totally worn out allowing play in the suspension.

Axles can be either under-sized by the manufacturer or they can be faulty. I read a thread the other day on another forum where Lippert had a run of bad axles in around 2010 used on one specific make and model of TT. Owners were all having tire issues and it wasn't until people started to post their problems that they realized all were traced to the same root cause.

Here's a whole other cause of tire problems that I doubt many know about. Weak frames can cause alignment issues. Some frame designs are inherently weak. The frames that have fabricated I-beams made from 3 pieces of sheet steel welded together lengthwise have a LOT of flex in them. The cross-bracing from one I-beam to the other is often 2x2 welded at the vertical mid-point of the beam. Some frames use 6" tall spring hangers as opposed to 4" tall. Some of these frames have no re-inforcement in the area of the spring hangers. This is all a recipe for constant and excessive movement of the bottom of the spring hangers from side to side from side force as in cornering or lane-changing. Then the spring hangers move from side to side, the axle tubes are forced to bend and the wheels go way out of camber. Axle tubes are very thin and bend easily.

Here's three pics to illustrate what can happen with one of these weak frames. In one photo, the side of the trailer is being pushed by a forklift to simulate side (lateral) forces while towing and the wheels go way out of camber. The 2nd is making a tight turn out of a CG. The last pic shows distortion and damage in the bottom of the I-beam from the spring hangers continually moving side to side. The spring bushing were all totally shot. This is in a brand new unit! Note that there are no gussets or 2x2 tubing welded to the underside of the lower flange as on some frames. The only mileage was almost entirely from plant to dealer. This amount of flex will cause uneven tire wear. Not sure what it would look like but maybe the center would look okay and the inside and outside areas would be worn?

One thing that can be done to reduce side to side frame flex is to install cross-bracing between the right and left side spring hangers. You can either make your own or buy the kit that Mor/Ryde has. If you do have a lot of frame flex and don't address it, you may very well end up with serious frame cracks down the road. Fixing it is waaay beyond an alignment job and if it's bad enough, it never can be made right like it should have been to start with. I've seen these weaker frames on about 6 different makes and models of ultra-lites now and they do it all for the sake of saving a few miserable lbs of weight. Some of the frames out there can barely support the factory dry weight when standing still.

- goducks10ExplorerI had to have it done on a Heartland TT with Lippert axles. A specialized shop did it. $190.00 total. They hook up chains and a hydraulic jack and bend the axles back to straight.

Here's how it's donehttp://www.youtube.com/watch?v=pRyTeqYuGBk

About Travel Trailer Group

44,056 PostsLatest Activity: Jun 25, 2013