jyrostng

Jul 02, 2013Explorer

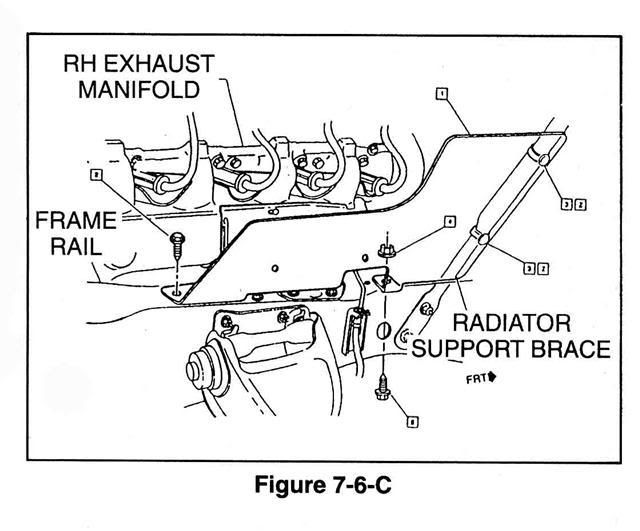

P30 chassis attachments to frame and spark plug wire issues

I have a 1989 30' P30 Southwind, going over rough roads causes a lot of banging. Are all the connections from the frame to the body supposed to be welded? Both front body support steel tubings where they ride on the frame are not welded.

The leaf springs in the rear look collapsed. Will running more air in the rear bags help that. I normally run 45 front and back, the rears max is 100psi, at 45 it looks like the bag halves are touching and that might be a cause of some of the rear banging over bumps.

I bought the best plug wires possible, I have them in the stock metal protectors with the insulator sleeve inside.(454) The plug wire ends keep burning up. The last set were borg warner. They didn't melt, they crystalized after a 800 mile trip in the summer heat. I have the stainless tube exhaust for headers. Is there a fix for this?

The leaf springs in the rear look collapsed. Will running more air in the rear bags help that. I normally run 45 front and back, the rears max is 100psi, at 45 it looks like the bag halves are touching and that might be a cause of some of the rear banging over bumps.

I bought the best plug wires possible, I have them in the stock metal protectors with the insulator sleeve inside.(454) The plug wire ends keep burning up. The last set were borg warner. They didn't melt, they crystalized after a 800 mile trip in the summer heat. I have the stainless tube exhaust for headers. Is there a fix for this?