Steve6l

Jun 11, 2014Explorer

Reese WD head clarification

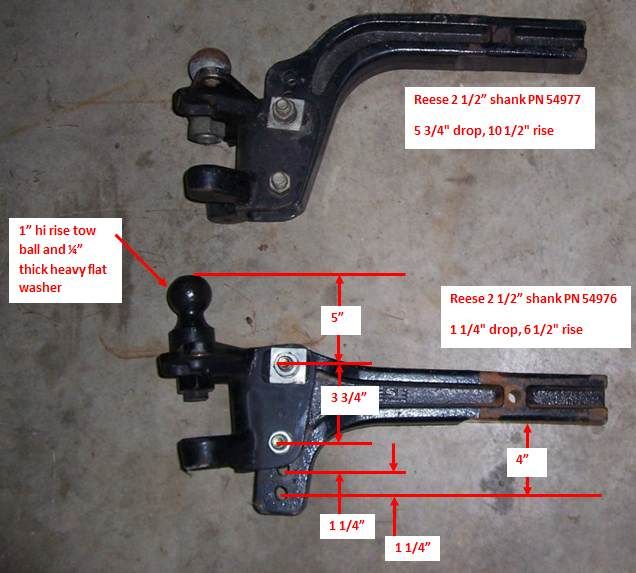

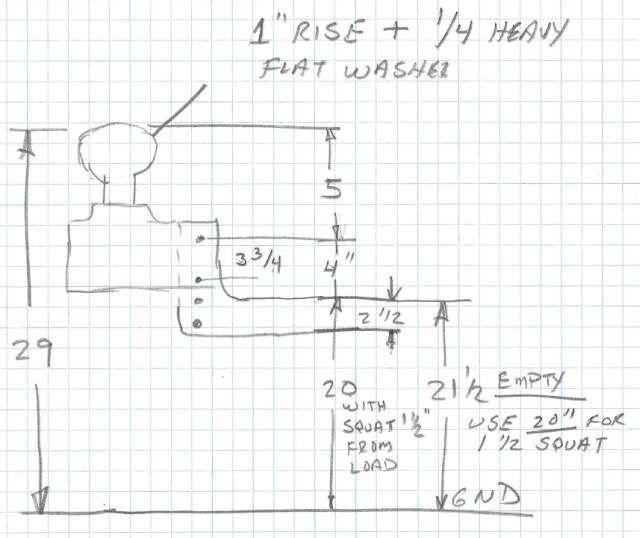

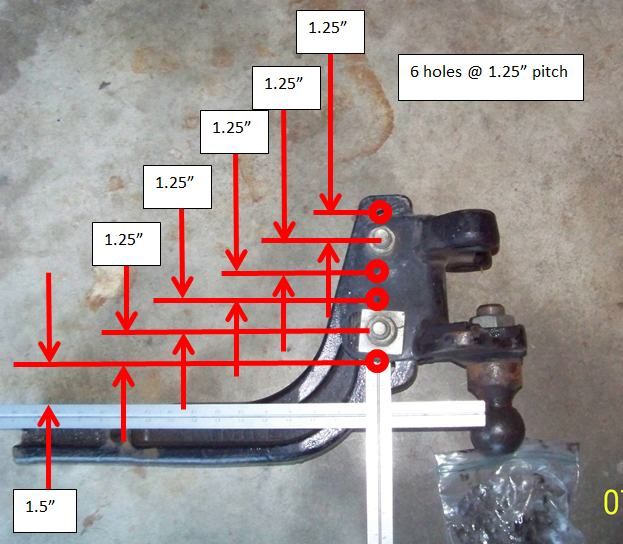

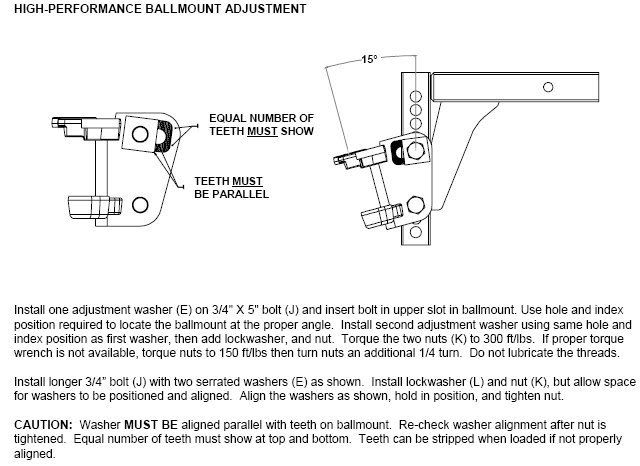

Hey Guys I have a Reese weight distributing hitch with trunnion bars along with dual cam setup.

It was purchased in 2010 may but wether it was made in that era is unknown. It came with 1200/12000 bars

I'm trying to distinguish which hitch head I have and what the weight

ratings are on for it.

My trailer has a 1200 pound dry weight and is a toy hauler so when

loaded down hitch weight decreases a max of about 200 pounds so I have

picked 1500 pound trunnion bars to get the job done. I'm wondering if the head will work with them and be rated to support them.

I have done a lot of searching online for info on the head and have

found that is a HP head/3 piece weld (not cast) but not sure on which weight rating. (No sticker on it anymore) now I have seen pictures of identical heads with 1200,12000 as max and alsopictures with the sticker showing 1700,17000 max.

Main reason is I want to be safe and I want the hitch to be effective

Also with my gold dual cams I'm wondering which ones I might have?

With the dual cam system the 26002 retails for about $200 and the

26025 retails for about $450

Mainly I'm wondering here why the huge price difference from

retailers?(225%) is there a difference in quality?

From what I read online the 26002 originally gold and then changed to

silver. And once it changed to silver the 26025 was released in gold.

Kind of wondering which one of the gold ones I actually have?

Thanks for any help

Steve

It was purchased in 2010 may but wether it was made in that era is unknown. It came with 1200/12000 bars

I'm trying to distinguish which hitch head I have and what the weight

ratings are on for it.

My trailer has a 1200 pound dry weight and is a toy hauler so when

loaded down hitch weight decreases a max of about 200 pounds so I have

picked 1500 pound trunnion bars to get the job done. I'm wondering if the head will work with them and be rated to support them.

I have done a lot of searching online for info on the head and have

found that is a HP head/3 piece weld (not cast) but not sure on which weight rating. (No sticker on it anymore) now I have seen pictures of identical heads with 1200,12000 as max and alsopictures with the sticker showing 1700,17000 max.

Main reason is I want to be safe and I want the hitch to be effective

Also with my gold dual cams I'm wondering which ones I might have?

With the dual cam system the 26002 retails for about $200 and the

26025 retails for about $450

Mainly I'm wondering here why the huge price difference from

retailers?(225%) is there a difference in quality?

From what I read online the 26002 originally gold and then changed to

silver. And once it changed to silver the 26025 was released in gold.

Kind of wondering which one of the gold ones I actually have?

Thanks for any help

Steve