Vegas1

Feb 29, 2016Explorer

FWS Major Failure (see photos) *UPDATE*

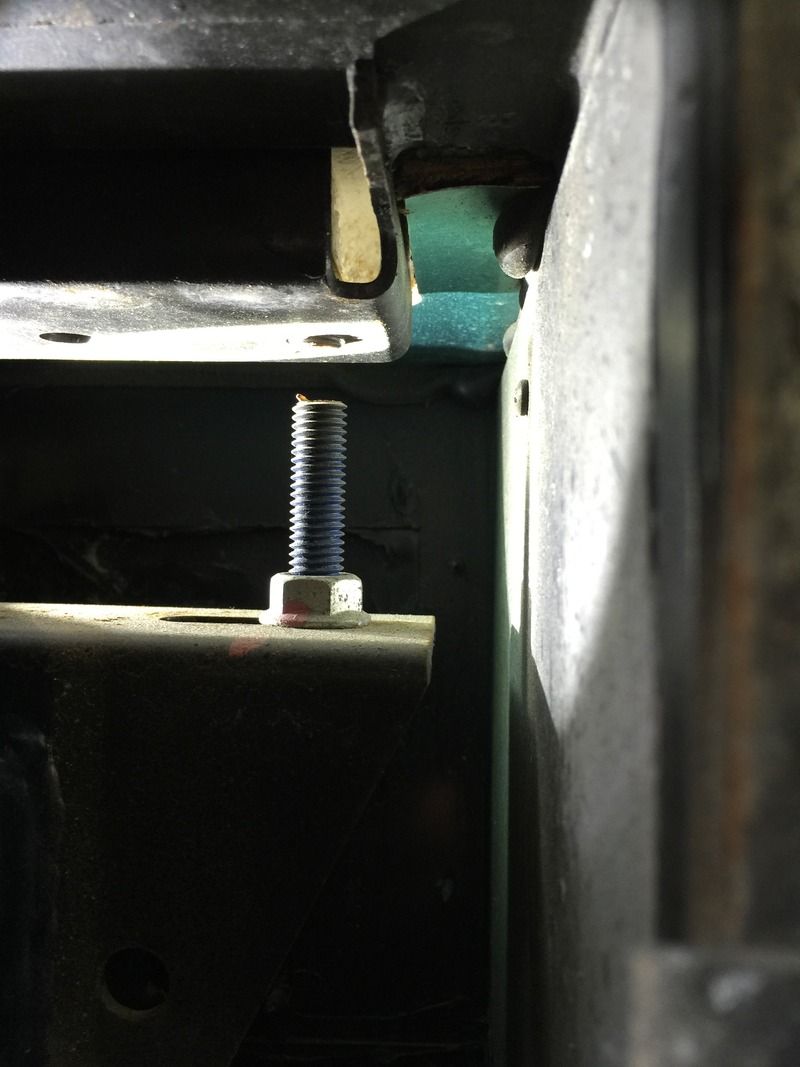

Today I noticed the outside end cap to the Power Gear ram was getting hung up when retracting the full wall slide. Upon closer examination, it was discovered that two bolts that secure the floor to the ram had sheared off, causing the center of the slide to sag about 1/2". I brought it to the local WInnebago Service for diagnosis and repair. They determined that it was going to be a very difficult fix since you can barely get one hand into the area. The two outside Rams were doing all the work. If this was not discovered, who knows what kind of failure would have occurred. They called factory service and it was recommended that the ram be jacked up to close the gap between the sheared bolt and weld it in place.

I'm not sure if this is going to reduce the integrity. Hoping Extended Warranty will pay for the repair since it appears to be a manufacturer defect. Any suggestions?

I'm not sure if this is going to reduce the integrity. Hoping Extended Warranty will pay for the repair since it appears to be a manufacturer defect. Any suggestions?