Hi mrekim,

I feel your pain and frustration. And I can tell you are open minded about this trying to learn as much as you can along the way.

This issue goes beyond the Reese snap up. Being open minded lets look at some other hitch manufactures and see if the same thing would of occurred with the frame and snap up. I picked these brands specifically as the snap up concept is the same as the Reese.

http://eaz-lift.com/eazlift/ EAZ lift. They have been around a long time even if recently acquired by Camco.

http://www.huskytow.com/product/trunnion-bar-weight-distribution-hitch/ Husky Towing Products. These folks have been around a long time using the same concept snap up.

http://www.curtmfg.com/Category/80/Weight%20Distribution Curt Mfg. A reputable name in the industry selling the conventionla WD hitch.

http://www.vtowing.com/About.aspx Valley Towing Products, Their web site I cannot seem to navigate right or something is not working. Here is a pic of the hitch from Cabelas

Valley hitchThere are others on the market that make the same style snap up, Robin Industries etc. All those style hitches have the same underlying snap up principal of forces. Granted some may be bent to be better on the 90 degree top bend, however the side load on the frame is not that much different. They are all no drill snap ups as listed. Have to dig into if they recommend bolting on higher TW's

I have not yet figured out if the DC addition to the WD hitch created all this frame issue. Not that anyone is yet pointing to the DC to aggravate this frame bend at the snap up issue, just I myself have not connected those dots yet. So this leaves us with your exact A frame setup, your TW, your very capable tow vehicle, 1,200# WD bars and a WD hitch hanging on a snap up bracket of the Reese “style”.

It is a fact that making a turn with a conventional WD hitch where the truck and trailer wheels are on different surface angles changes the hitch head tilt in relation to the trailer A frame. If the trailer wheels are on level ground and the truck on a surface that on angle (say 5 or 10 degrees for example) in relation to the TT, the hitch shank in the back of the truck is going to follow the truck and the hitch head with the tow ball in the coupler will pivot the WD bars. The hitch head movement will change the loading on the inside and outside turn WD bar. How much it will change will depend on the angle and the head tilt of the hitch.

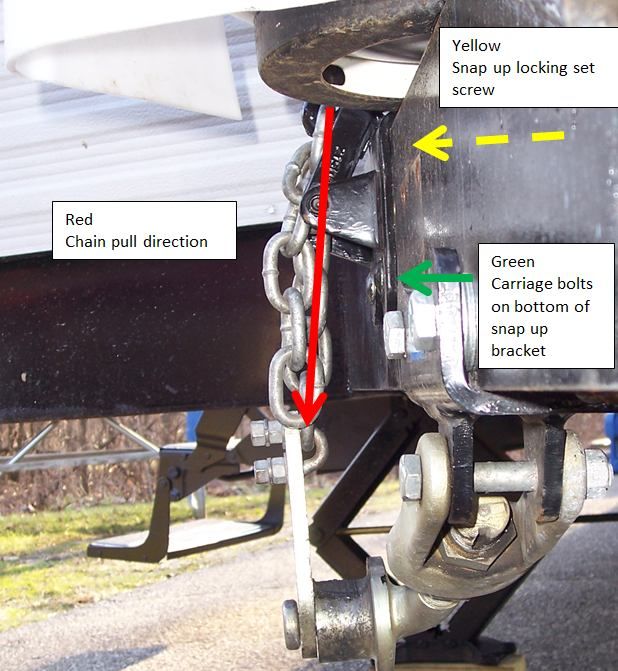

On the DC, since the chain does not swing like a non DC WD hitch it is easier to spot that the inside turn WD bar can totally unload in spring force. And it does not take very much angle between the truck and trailer. I have seen it and measured it in my own driveway.

On the non DC hitch the chain attached to the WD bar will swing towards the TT. Since it is attached to the WD bar, it is harder to see that inside WD bar unloading. And it may take more angle difference between TV and TT to go to zero load, however the load is still significantly reduced because the hitch head is titled in a force unloading direction.

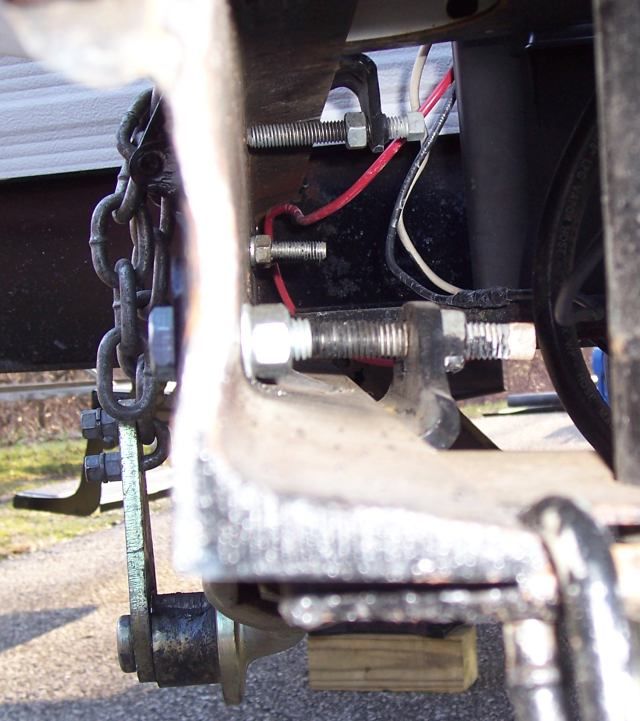

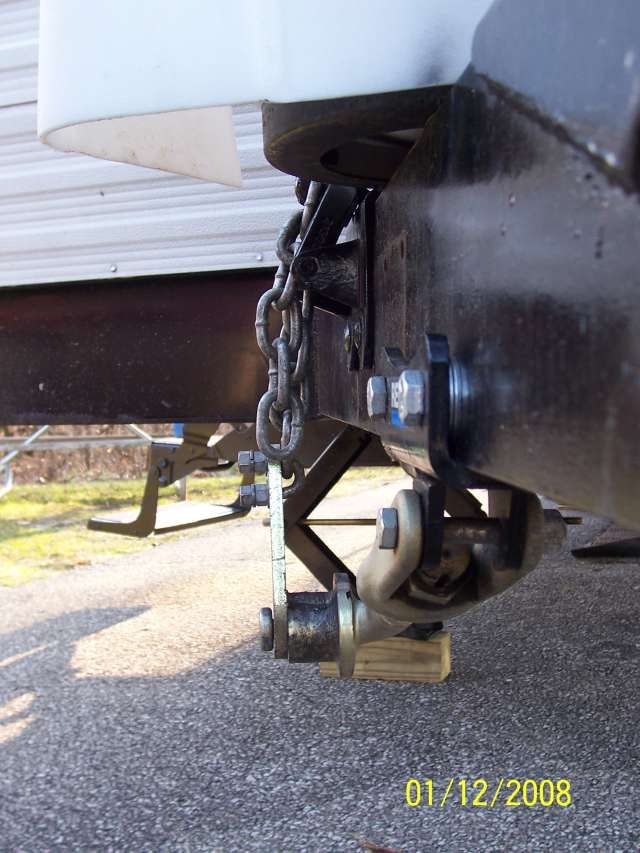

Once the inside turn WD bar unloads in force or a majority of the force, the chain force pulling on the snap up of the outside turn WD goes very high. This is where the heavy force comes from that did the damage to your A frame.

The A frame has to take this side pulling chain force directed into the frame rail by the snap up and not deform under load. Reese may be getting the black eye on this one as it was the brand in use at the time. The question is what industry standard exists for A frames on trailers that are known to have to use a WD hitch? And even more so, is there are standard for side loads of a snap up bracket? I myself do not yet know of one. I will start looking though. The Hitch manufactures and the TT manufactures may need to talk more. Who is the one to take the lead? Build a hitch that works on every TT or build a TT that works with the WD hitches now avaible on the market? The conventional WD hitch has not changed much in the last 50 years... TT A frames have.

I have a flat deck equipment trailer at home, rated for 9,900#, The A frame is made from 6” channel and there is a 6” wide C channel welded in left to right between the frame rails near the sanp ups as part of a hydraulic tilt lift. I can post a pic later tonight. This thing is even beefier then my 6” channel , 10,000# camper. Many enclosed cargo trailers use tube A frames. I have towed them often just do not own one right now to go out and measure the tube thickness. Many in the 10,000# class may be 6 to 8" structrual tubing.

Point in this is the A Frame is in the middle of the mix. Would any one of those other brands that have been around a long time be any different than what the Reese did? They are all no drill snap ups and the length of the snap up it not that much different. The pressure points acting on the A frame side wall are similar. If Coachman comes back and declares the Reese DC is not compatible with their trailer frame, did they also wipe out all the other brands that use the same style snap up?

More to think on.