mrekim wrote:

But we may have one more puzzle piece to fit:

This is the other side of the frame. It didn't have the snap-up failure and there isn't a big dent from the snap up pinch bolt.

After the latest new discoveries I have a hypothesis to what "might" have contributed to this.

What we do know is the frame deflected inward permanently. We can see it. In order to bend inwards it "appears" the cam arm rotated CW as viewed from the front. This pic shows what I am referring to.

Now we just need to sort out what caused the cam arm to rotate enough to cause permanent deformation of the frame. When mrekim showed us this pic, it started the thinking process. Note: We can tell the mold that cast the arm on the left is slightly different on the cam outer boss area then the arm on the right. It also appears the cam does not extend as far from the threaded shaft. It might be a picture anomaly. Cannot confirm from this on pic. Do you have a top view looking straight down?

Reese upgrade the frame bracket. This is now the 3rd upgrade to the HP DC. Let's look back to the early days when the new HP DC came out to offer a different mounting than the older standard DC that used U bolts to hold the DC to the frame.

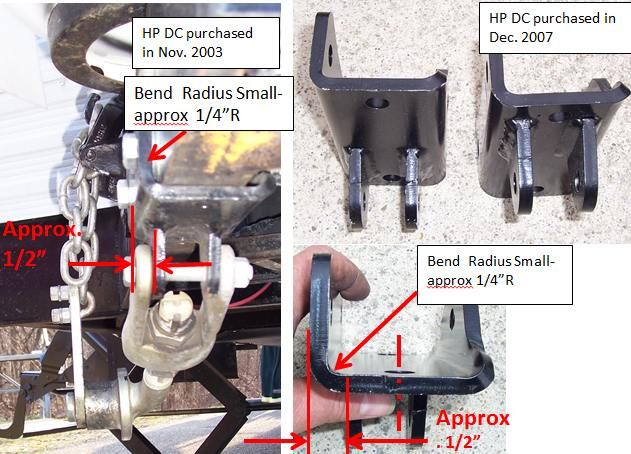

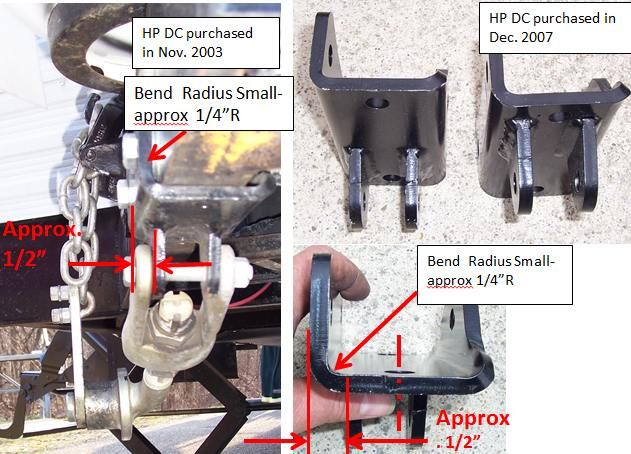

I bought my first HP DC in late 2003. It had been on the market for a few years by then. In late 2007 I bought another one. Across these years the HP DC remained unchanged. I want to point out the distance from the outside of the frame plate to the side of the 1st clevis plate. Also the bend radius of the frame plate.

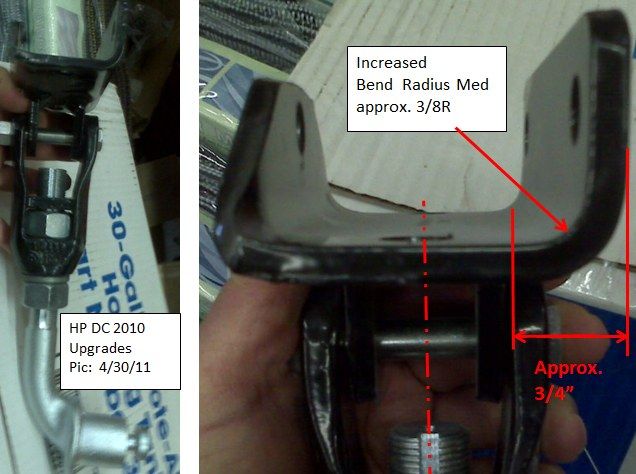

This vintage frame bracket allowed the WD chain to hang a certain distance out from the frame. The distance from the outside of the frame plate to the 1st cam arm yoke clevis was set by the approx. 1/2" distance show in this pic.

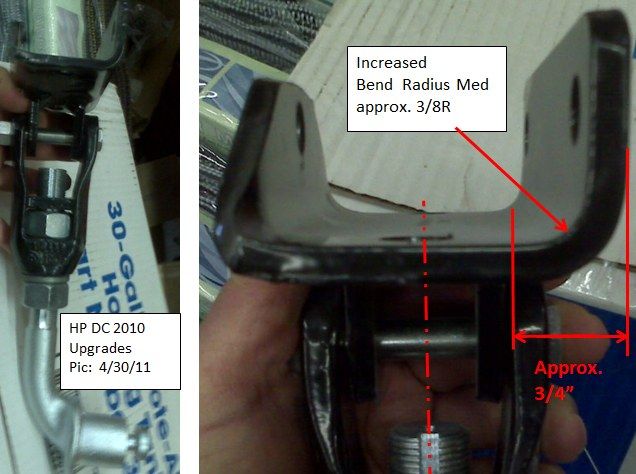

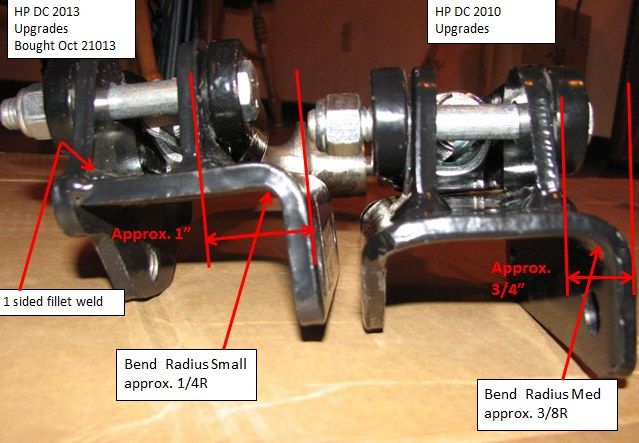

In 2010 Reese upgraded the design. Believed to help some of the cam arm binding problems on some trailer A frames. The A frames with the ball coupler on top had the larger issues unless the owner did certain installation measures to prevent the cam arm binding in compound angle turns. In this design upgrade they changed the frame plate in addition to the cam arm. The frame plate bend radius increased where it contacts the edge of the frame. They also shifted over cam arm by approx 1/4". The cam arm yoke now mounts 3/4" from the outer edge of the frame plate.

In this 2010 vintage they also had a bent chain plate to help move the WD chain closer to the frame. Issues started to show up with larger frame plate radius where is could rock on the frame. Over time this could work loose the screws if the installer did not shim out the frame plate with washers like the channel iron frames need. And then the owner would inadvertently mount the chain plate backwards. It is not intuitive to all that pulling on the chain way off center is not a good thing.

mrekim reported in a call to Tech Support Reese has gone back to the straight plate as too many bent chain plates where getting installed wrong. Reese was trying to do a good thing by getting rid of some of the off center chain load with shifting over the cam arm and the bent chain plate. However it was not user "proof". I have no idea why they increased the frame plate bend radius.

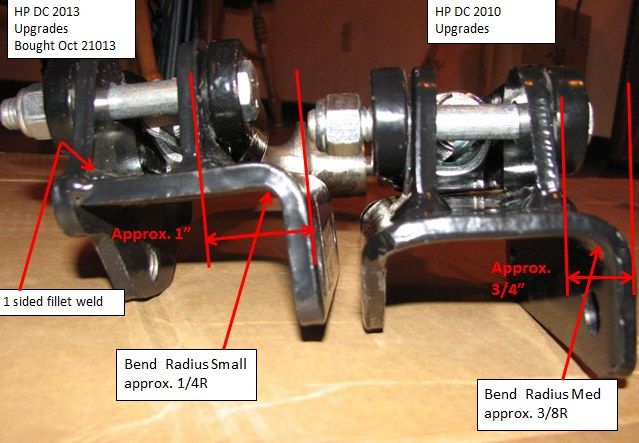

Now in 2013 we have found another upgrade to help the off center chain pull. Or at least it is my opinion this is what they did it. The frame plate was changed again. They brought the smaller bend radius back of the year 2001 vintage and again moved the cam arm over another approx 1/4". This now is approx 1" from the outer side of the frame plate face.

Here is mrekim's frame bracket where I highlighted some features. The 1" is an estimated distance based on relation to the known 1/4" thick frame plate. It might be 7/8" or 1 1/8". Or my estimate is right on.

The smaller frame plate radius is positive move. Making attempts to help lessen the off center chain pull is a positive step as well. However I am not a fan of a 1 sided fillet weld in how they made the bracket.

So how does any of this relate to mrekim's bent in right side A frame? This side did not bend the snapup yet we have evidence the cam arm rotated enough to cause the frame to bend.

There are a few factors in this equation. Some are these 3. Their may well be more however these 3 come to the top of the list. Anyone with more, please add.

1. A new 2013 1" offset on the cam arm frame plate.

2. An 6" A Frame made from 11 gage tube steel on an 1,100# loaded TW which is very inline for the size of camper.

3. Another factor not yet discussed is hitching up. Mrekim when you hitch up do you flip the snap up's real easy either by your hand or gently pressure on the pipe OR do you pull full weight of the spring bar with the pipe to snap up? What do you do tongue jack during snapping up?

Before I go down the road of no. 1 and 2, need to know how number 3 is performed. Please give us the details on how you snap up?

Hope this helps

John