Forum Discussion

126 Replies

- otrfunExplorer II

ShinerBock wrote:

Yup, I noticed the exterior portion in the image you posted was quite a bit different from the Ram.otrfun wrote:

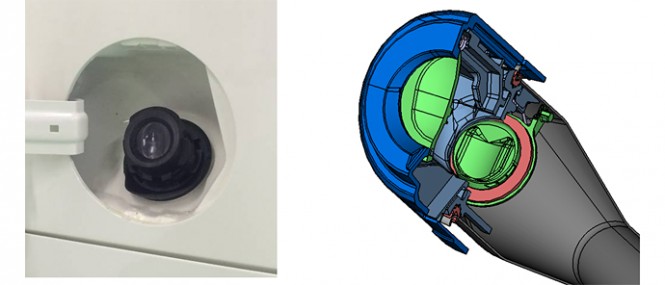

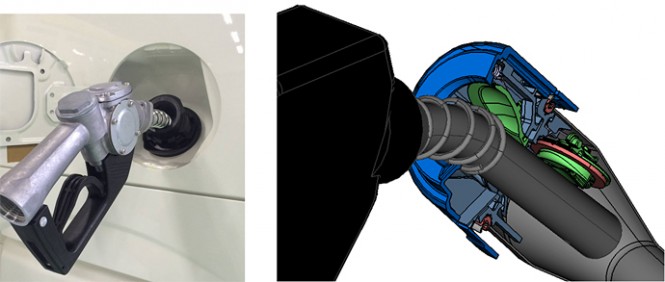

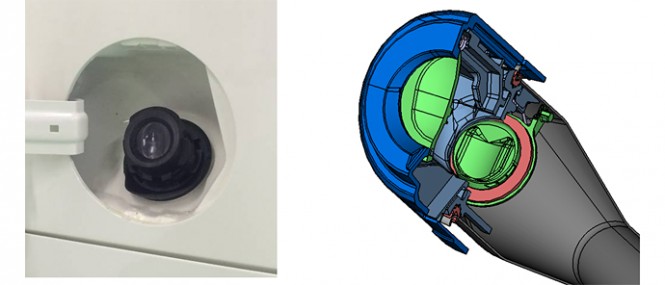

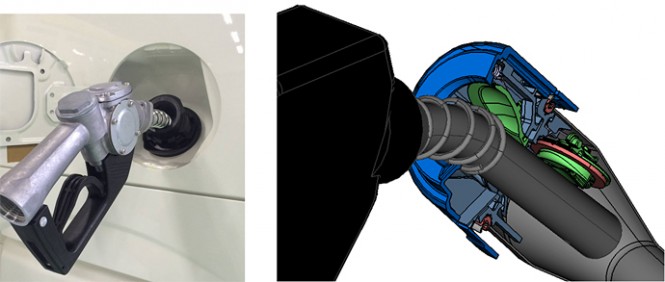

The image I posted was of Toyota's capless system that they have been using for years. I could not find a diagram of the Ram's system, but I just wanted to show the basic workings of it. The Ram system is somewhat different and does address some of what you state here.

Very fine dirt and debri flows around the fuel door while driving. Black residue tends to collect around the green base of the capless assembly in between fillups on my truck---no doubt this is dirt attracted to the minor diesel overspill during every fillup. Needless to say if collects there, what's to stop it from collecting elsewhere?

As far as I can tell there is no air-tight gasket on the 1st flap. Over time the simple movement of air laden with very fine dirt and debri can easily flow through and around the 1st flap down to the 2nd flap. Again, the sticky diesel fuel residue left after refueling will only hasten the collection of fine dust and dirt inside the area between the 1st and 2nd flap.

Yes, the 2nd flap has a gasket (noted in red) that prevents contaminants from falling down the fuel channel when one is not refueling. However, when the fuel nozzle is inserted for fueling purposes the 2nd flap folds down (along with any potentially collected surface contaminants), completely exposed, inside the fuel channel.

Granted, I can see how some would dismiss this as a minor, insignificant risk---which it very well may be.

However, until I read something more definitive and objective in terms of the actual risk, I've elected to use an aftermarket cap with an air-tight o-ring which negates any chance of any contaminants (airborne or otherwise) from flowing down and potentially collecting inside this cavity while driving.

The one thing I find very humorous about this is that everyone is getting worried over the cappless system of the Ram's yet the Cummins is the only one of the three that does not have a fuel contamination issues.

For those of you who have owned (or operated) a number of diesel trucks, calculating the risk of fuel contamination is probably an easy process. FWIW, my '16 Ram 3500 Cummins is my first ever diesel. As such, I'll be playing it much more cautious until I get more confident with exactly how the various fuel contamination risks play into things in the realworld. In any case, very good to hear the Cummins is not prone to fuel contamination issues! - NJRVerExplorer

ShinerBock wrote:

otrfun wrote:

Very fine dirt and debri flows around the fuel door while driving. Black residue tends to collect around the green base of the capless assembly in between fillups on my truck---no doubt this is dirt attracted to the minor diesel overspill during every fillup. Needless to say if collects there, what's to stop it from collecting elsewhere?

As far as I can tell there is no air-tight gasket on the 1st flap. Over time the simple movement of air laden with very fine dirt and debri can easily flow through and around the 1st flap down to the 2nd flap. Again, the sticky diesel fuel residue left after refueling will only hasten the collection of fine dust and dirt inside the area between the 1st and 2nd flap.

Yes, the 2nd flap has a gasket (noted in red) that prevents contaminants from falling down the fuel channel when one is not refueling. However, when the fuel nozzle is inserted for fueling purposes the 2nd flap folds down (along with any potentially collected surface contaminants), completely exposed, inside the fuel channel.

Granted, I can see how some would dismiss this as a minor, insignificant risk---which it very well may be.

However, until I read something more definitive and objective in terms of the actual risk, I've elected to use an aftermarket cap with an air-tight o-ring which negates any chance of any contaminants (airborne or otherwise) from flowing down and potentially collecting inside this cavity while driving.

The image I posted was of Toyota's capless system that they have been using for years. I could not find a diagram of the Ram's system, but I just wanted to show the basic workings of it. The Ram system is somewhat different and does address some of what you state here.

The one thing I find very humorous about this is that everyone is getting worried over the cappless system of the Ram's yet the Cummins is the only one of the three that does not have a fuel contamination issues.

Dirt would be the least of my worries with that second cap.

I would like to know what happens when the little spring that snaps that second cap shut when your done, breaks off and it and the cap fall down into the tank. - ShinerBockExplorer

otrfun wrote:

Very fine dirt and debri flows around the fuel door while driving. Black residue tends to collect around the green base of the capless assembly in between fillups on my truck---no doubt this is dirt attracted to the minor diesel overspill during every fillup. Needless to say if collects there, what's to stop it from collecting elsewhere?

As far as I can tell there is no air-tight gasket on the 1st flap. Over time the simple movement of air laden with very fine dirt and debri can easily flow through and around the 1st flap down to the 2nd flap. Again, the sticky diesel fuel residue left after refueling will only hasten the collection of fine dust and dirt inside the area between the 1st and 2nd flap.

Yes, the 2nd flap has a gasket (noted in red) that prevents contaminants from falling down the fuel channel when one is not refueling. However, when the fuel nozzle is inserted for fueling purposes the 2nd flap folds down (along with any potentially collected surface contaminants), completely exposed, inside the fuel channel.

Granted, I can see how some would dismiss this as a minor, insignificant risk---which it very well may be.

However, until I read something more definitive and objective in terms of the actual risk, I've elected to use an aftermarket cap with an air-tight o-ring which negates any chance of any contaminants (airborne or otherwise) from flowing down and potentially collecting inside this cavity while driving.

The image I posted was of Toyota's capless system that they have been using for years. I could not find a diagram of the Ram's system, but I just wanted to show the basic workings of it. The Ram system is somewhat different and does address some of what you state here.

The one thing I find very humorous about this is that everyone is getting worried over the cappless system of the Ram's yet the Cummins is the only one of the three that does not have a fuel contamination issues. - ShinerBockExplorer

FishOnOne wrote:

Wild Card wrote:

However water in the fuel has nothing to do with the emissions related problems that they are in court over...and I dont understand why its just the 2500's as the 3500's have the same system.

What I read was the trucks are not meeting the emission requirements and either the 3500 has a different emissions requirement or it was an over sight which I would guess it to be the latter.

Perhaps Shiner can comment on this as I don't really follow the emissions requirements.

I don't think the pick up 3500 has any different emissions than the 2500/ The cab and chassis version of the 3500 should since they have to run a engine dyno certification instead of a chassis certification like the pick ups.

From what I have read from other articles about this, it seems that moisture can some how cause the SCR to deactivate. That is about all I know about it so far. - otrfunExplorer II

Walaby wrote:

Believe I'll pass on the paper towel tip, Mike. Thanks though. The aftermarket fuel cap (and o-ring) will provide sufficient protection for my needs :W

Make sure you wipe the pump nozzle off with a paper towel before you put it in the tank. There might be dust or dirt particles on the nozzle that will definitely get into the tank and through the second flap.

On second thought.. better not use a paper towel, as paper particles and dust might get in. Not sure which one is worse.

Mike

FYI, to put this aftermarket fuel cap discussion in perspective for those that may not be aware, dirty injectors are not covered by the Ram Cummins basic or powertrain warranty. Wild Card wrote:

However water in the fuel has nothing to do with the emissions related problems that they are in court over...and I dont understand why its just the 2500's as the 3500's have the same system.

What I read was the trucks are not meeting the emission requirements and either the 3500 has a different emissions requirement or it was an over sight which I would guess it to be the latter.

Perhaps Shiner can comment on this as I don't really follow the emissions requirements.- WalabyExplorer IIMake sure you wipe the pump nozzle off with a paper towel before you put it in the tank. There might be dust or dirt particles on the nozzle that will definitely get into the tank and through the second flap.

On second thought.. better not use a paper towel, as paper particles and dust might get in. Not sure which one is worse.

Mike - otrfunExplorer II

ShinerBock wrote:

Very fine dirt and debri flows around the fuel door while driving. Black residue tends to collect around the green base of the capless assembly in between fillups on my truck---no doubt this is dirt attracted to the minor diesel overspill during every fillup. Needless to say if collects there, what's to stop it from collecting elsewhere?Bumpyroad wrote:

Easy, because the capless system is sealed but with two flaps, not just on cap. You guys keep thinking there is no seal with a capless design, but that is just not the case. Just because you can't see that second sealed flap does not mean it isn't there.

I think you think incorrectly. how on earth could a capless system be better than one with a sealed cap?

bumpy

Say you pulled up to a fuel station while there was fine snow blowing like Grit was saying. You open your fuel door and remove the cap. BOOM, you are now exposing your fuel tank to all the contaminants of the air including fine snow until you stick the nozzle in. Even then, the filler neck is a lot bigger than the pump nozzle so you are still letting stiff in as you pump.

With the capless system, when you open your fuel door the first flap is keeping the fine snow out. You slide the nozzle past the first flap and the fuel tank is still sealed by the second flap that is another 6-8 inches down into the neck. The second flap opening is only big enough for a diesel pump nozzle to fit in so as you insert the nozzle it seals up the tank while you are pumping.

Here are a few images of the basics of how the capless system works.

As far as I can tell there is no air-tight gasket on the 1st flap. Over time the simple movement of air laden with very fine dirt and debri can easily flow through and around the 1st flap down to the 2nd flap. Again, the sticky diesel fuel residue left after refueling will only hasten the collection of fine dust and dirt inside the area between the 1st and 2nd flap.

Yes, the 2nd flap has a gasket (noted in red) that prevents contaminants from falling down the fuel channel when one is not refueling. However, when the fuel nozzle is inserted for fueling purposes the 2nd flap folds down (along with any potentially collected surface contaminants), completely exposed, inside the fuel channel.

Granted, I can see how some would dismiss this as a minor, insignificant risk---which it very well may be.

However, until I read something more definitive and objective in terms of the actual risk, I've elected to use an aftermarket cap with an air-tight o-ring which negates any chance of any contaminants (airborne or otherwise) from flowing down and potentially collecting inside this cavity while driving. - Wild_CardExplorerI went to home depot and bought a 1.5'' plumbing test plug...(kinda like a boat plug has a wingnut to tighten and seal) the 1st day I brought my Ram home. Just for a sense of security. There are 2 flaps in the fuel fill neck, and I personally see no way of water getting in the tank...not to the point of big issues

However water in the fuel has nothing to do with the emissions related problems that they are in court over...and I dont understand why its just the 2500's as the 3500's have the same system. - ShinerBockExplorer

Bumpyroad wrote:

I think you think incorrectly. how on earth could a capless system be better than one with a sealed cap?

bumpy

Easy, because the capless system is sealed but with two flaps, not just on cap. You guys keep thinking there is no seal with a capless design, but that is just not the case. Just because you can't see that second sealed flap does not mean it isn't there.

Say you pulled up to a fuel station while there was fine snow blowing like Grit was saying. You open your fuel door and remove the cap. BOOM, you are now exposing your fuel tank to all the contaminants of the air including fine snow until you stick the nozzle in. Even then, the filler neck is a lot bigger than the pump nozzle so you are still letting stiff in as you pump.

With the capless system, when you open your fuel door the first flap is keeping the fine snow out. You slide the nozzle past the first flap and the fuel tank is still sealed by the second flap that is another 6-8 inches down into the neck. The second flap opening is only big enough for a diesel pump nozzle to fit in so as you insert the nozzle it seals up the tank while you are pumping.

Here are a few images of the basics of how the capless system works.

About Travel Trailer Group

44,044 PostsLatest Activity: Jul 29, 2025