Hi Mrekim,

You have done well working through this. I'll add some not yet stated.

For a 6" wide A frame sure looks like what you have, you need a 1" hi rise tow ball with the Reese HP trunnion bar head. It lowers the head down enough to help get out of the binding issues. You have already made it to this point. I added a 1/4" thick heavy flat washer to get a little more. Both will work.

The hi rise tow ball "must" be stamped on top for the full GVWR of your camper or larger. Check that as some hi rise tow balls have very low ratings while others can be 25,000# goose neck tow balls.

Here are some limitations. You are doing well using the floor jack however there are other limiters in this. Shank length and TT front end design.

See here. This is a measured 74 deg left turn. 90 degrees was mentioned and that is not going to happen on a TT with a 50 degree inclusive angle A frame. While you are looking see the truck bumper and the WD shank length.

Your goal is to adjust the hitch the best you can and not have it be the binding point in a hard left turn. Pending the shank length and TT design, the tail light can crash into the camper before the hitch binds. Shorter shanks crash faster but offer a level of being slightly more stable. Longer shanks allow more degrees of turning to not hit the tail light but then the LP tanks are there. See here

A 74 degree left turn going forward may be all the turning radios of your truck can do any way. Backing up on the left side, well you can crash something and it may be the LP tanks with the bumper. There is also so much a conventional WD hitch can do in regards to turns. 74 degrees is good. You start going a lot past that and you going to break something in the hitch. It happens on my prior Suburban with rear wheel steering at about 76 degrees. See here. Soon the right WD will fly out.

If you really want 90 degres, See the Pullrite 90 degree hitch. That hitch will give 90 degress.

So that is optimizing a left turn. The right turn with your ball coupler will be limited to 65 degree right. See here. The friction sway bar arm is going to hit at 65 degrees. There is not a lot you can do about that. And "most" times you turn sharper left than right so it often is not a problem.

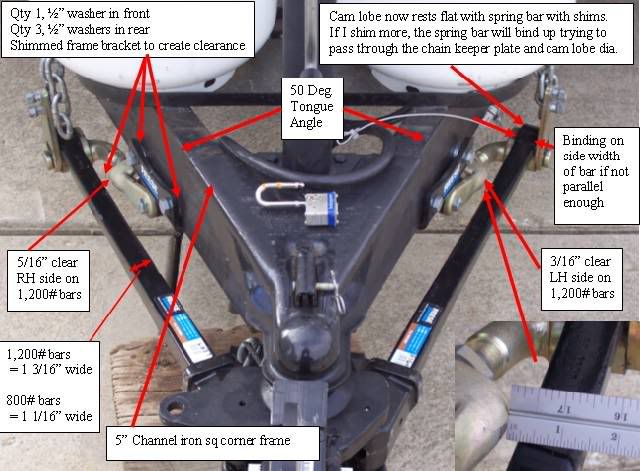

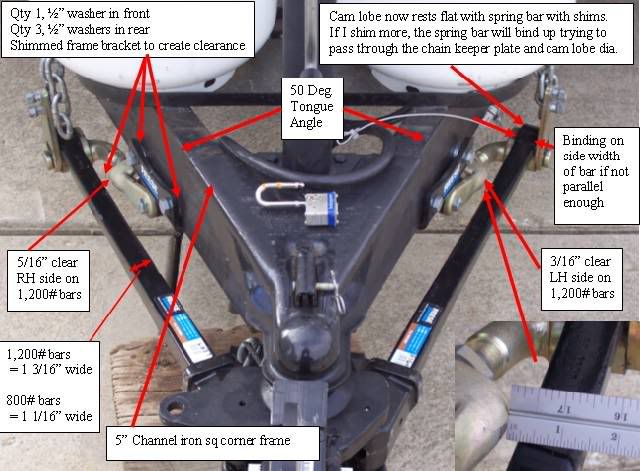

I see you have shimmed out the cam arms with attempts of making the WD bar mate better with the cam. I have done this. You can see it here on my older camper

However in my case I had square corner channel iron A frame and you have to shim out the frame plates so the bend radius of cam frame plate does not bind on the square corner of the frame. Even some tight radius tube frames may need a washer. So as long as you have clearance your good. adding 1 extra washer to help even out the cam is about all you need. Just make sure the frame plate is dead flush up agasint the bottom of the A frame rail. Use a C clamp is best

Here is the sq corner issue you need to shim out for.

What you need to do is mark the left and right WD bars and always use them on the same side. Over time they will wear to be a perfect match between the cam and WD bar. See here after 25K miles.

and the WD bars

I am still using those same cams, just heavier bars. Now at 50K miles and the wear is not that much more.

Now to the emergency breakaway switch, this should be set with the proper saftey chain length. This topic can get as much attention as gas verses diesel... See here for how I came to do this and why.

WD Hitch Safety Chains Hook Up (Pic's) Searching the forum you will finds "lots" of debate posts on this.

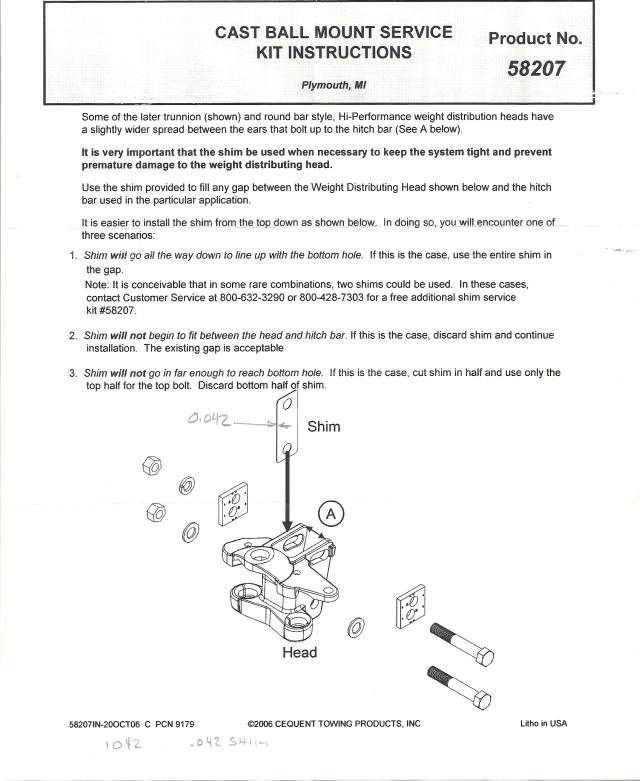

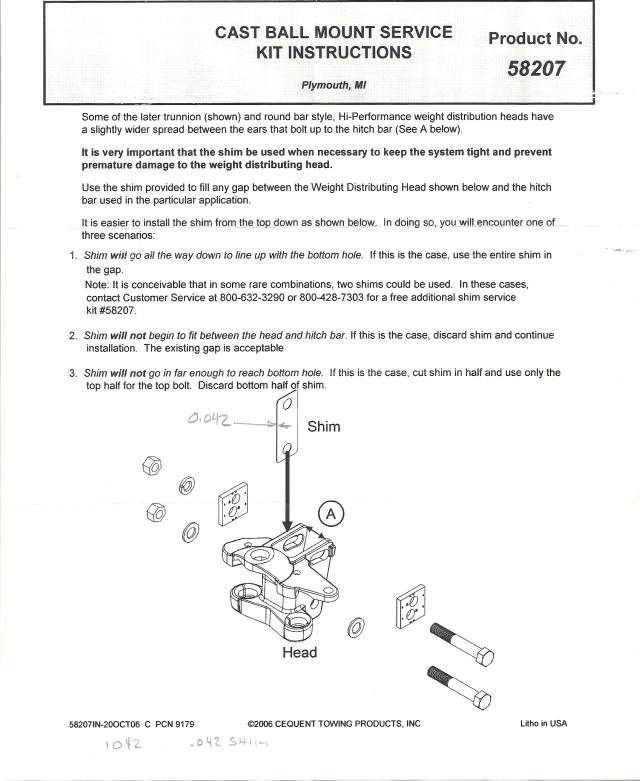

Your 2 style hitch heads. You have the older 3 piece welded head and the new 1 piece all cast head that replaced it. The all cast new head has a higher boss for the tow ball to give more ball nut clearance and a high ball platform to help with binding. The Hi rise tow ball does this on the older 3 piece style. Enough years ago the all cast head had some issues. Some of it stemmed from shank fit up. The all cast head wrapped around a small shank can set up a problem of over flexing the C shaped part of the head and some heads cracked. There use to be a pamphlet that talked about a shim to be used if the play was too excessive. Like this

If you have a very loose fit between the shank and head on the all cast head, call Reese and they will send you a free shim is needed. Do not just tighten up the head trying to spring it closed. I have not seen or heard of any recent heads cracking like the once back in the early 2,000's which where before the 3 piece welded head. It seems Reese worked through what ever the issues were.

Oh and yes, like Barney says, set up the WD with the DC on. No need to set it up on the chains then start all over when you add the DC. I have set up many DC's and WD from the get go. It's not a problem. Don't know where you heard or read that as it seems out of context.

Hope this helps and good luck.

John