JBarca wrote:

---I'm assuming you just picked the 500# as a number to use in the calculation not knowing actual loaded TW's and TV/TT stats. If this correct?

The 500# per bar is a rough approximation based on the OP's scales data which showed 220# returned to the front axle when WD was applied.

If I had used a value of 1000# per bar, the calculated values would have been doubled.

On Edit: The 200# value was from a preliminary weighing.

Subsequent re-adjustment of the OP's WDH caused the TV's front axle to be returned approximately to the unhitched height.

If we assume the WDH caused 560# to be returned to the front axle,

the corresponding WD bar load would be about 1000# per bar.

For purposes of sway control, the longitudinal tension/compression in the WD bar acts like the tension/compression in a friction sway bar -- it resists a change in the angle between TV and TT.

It is interesting to note that a friction sway bar is factory-set to produce a friction force of 1100# compared to the WD bar tension of 2000# which I calculated for the 500# bar load.

My analysis does not depend on any assumptions about TV/TT angle or left to right tilt of the hitch head.

It only assumes the WD bar produces a given amount of vertical force against the cam and assumes enough change in TV/TT angle to make the end of the WD bar slide up and forward along the back side of the cam.

The effect of the friction will be present when swinging from zero to five degrees just as it would be when swinging from 40 to 45 degrees.

---The large tension on the right side of the A frame appears to be rolling the shank and possibly the truck a little. The shank for sure has a CW tilt as viewed from the TT. With your recent found force magnification in this extreme turn, this possibly might add new light to making a turn with the DC and the large loads that can come from it.

When there is a large TV/TT angle, any upward force on the rear end of a WD bar will tend to rotate the TV about its roll axis and about its pitch axis.

Because the TV's track width is much less than its wheelbase, it is much easier to make it rotate about the roll axis.

When the hitch head is able to rotate CW as shown in your photo, the slope of the front of the WD bar is reduced causing the load on the bar to be reduced.

---If the inside WD bar is unloaded by some amount, then WD is potentially reduced on left side bar leaving the right side WD to attempt/or add to carrying more of the WD load.

In a sharp turn, the slope of the front end of the inside WD bar will be significantly reduced and the load on that bar can go to zero.

However, that does not mean the load removed from the inside bar will be added to the outside bar.

As your photo shows, on the level surface, there was a left to right tilt of the hitch head because it is relatively easy to rotate the TV about its roll axis.

This means the outside WD bar might actually be subjected to less load than when the TV/TT angle was zero.

A question is, is this then a self multiplying force situation? First the DC friction effect creates a high load on one side of the A frame by increased chain tension. This increased tension can then roll the hitch head by some amount.---

No, it does not. The increase in chain tension, in my analysis, results from the compression in the cam bar which is due to the increased normal and friction force acting on the cam as the WD bar tries to slide up and over the cam.

The increased chain tension pulls down on the A-frame, but the compression in the cam bar exerts an equal upward force on the A-frame. The net downward force acting on the A-frame remains at, for my example, 500#.

---Does the roll action then even more increase the chain tension and further increase the friction force? Granted this turn is extreme in this case, however a 50 degree turn with a compound angle of 5 to 8 degrees of the hitch head can unload to zero the inside turn WD bar which can be assumed did happen in mrekins case.

I agree the inside bar can unload to zero, but that is a result of the decreasing tilt of the trunnion axis as the hitch head swings relative to the trailer.

Using those spec's I'm assuming you can calculate the tension in the WD chains when on level ground and the TV & TT are in a straight line. That puts this at a starting place of chain load when going straight ahead.---

Assuming zero pitch-axis rotational torque between ball and coupler:

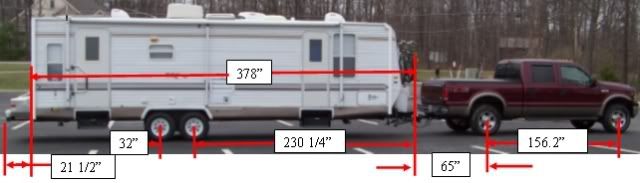

The load removed from the front axle would be 1260*(65/130) = 630#.

To restore 630# to the front axle, the combined WD bar force would have to be 630*130/(65+230+16) = 263#.

Assuming longitudinal distance from ball to snap-up brackets is 30", the combined chain tension would have to be 263*(230+16)/30 = 2157# or approximately 1080# per chain.

Of course, that assumes travelling straight ahead so there is no longitudinal tension/compression in the WD bars -- i.e. no friction force between WD bar and cam.

Since we do not yet know an accurate spring constant for the WD bar it may be a little hard to know the full tension in the chain when in the turn and what effect the hitch head roll created. The assumption is, the chain force will even be higher then the straight ahead chain load.

I would not assume the force will be even higher. It depends on how much rearward tilt there is when the TV/TT angle is zero and how much the rearward tilts of the trunnion axes change as the TV/TT angle changes.

Another question/topic: Did I understand your last statement correctly. For a 500# downward starting force from the TT acting on one WD bar, this translates into a 2,170# at the WD chain due to the increase from the breakaway friction load of the turn? And if so, is this then a 2,170/500 = 4.3 to 1 linear increase in WD chain load per pounds of down force? If linear, is it then if we have 1,000# downward force (fill in the number as needed) from the TT do we end up with a 4,300# WD chain load in a turn from the breakaway friction force riding up the cam?

I addressed this earlier. If my analysis is correct, a load of 1000# per WD bar and the other assumptions given in my free body diagram presentation would give a chain tension of about 4300# per chain.

Keep in mind that this is a dynamic process -- the TV/TT angle must be changing in order to generate the friction force.

If the TV and TT were being driven in a constant-radius circle, the TV/TT angle would not be changing and there would be no friction force.

Ron