mrekim wrote:

JBarca wrote:

The set screw drug the frame and headed towards the "bottom" of the frame. In order for the dig marks to go that direction the DC arm had to be lifted "up". Agree Yes/no?

I originally wrote that the chain was pulling up.... but went back and changed it.

When the WD bar is under tension, it's trying to pull the chain down. If the WD bar was centered exactly under the chain, there would be no twisting action. Since the WD bar is to the inside, there's a down force somewhere on the cam and the chain is resisting that force on the end of the cam. I think this creates a twisting action. This is why a small movement can be observed when the bars are snapped up (or when the tongue is let down - I'm not sure when it showed up).

JBarca wrote:

Now the frame crush at the DC frame plate. This pic aligns with the set screw rotation. The DC arm had to rotate "up" in order to crush the frame in. Both the set screw and the frame inward crush support an upward force doing this damage.

Yes, counterclockwise when facing the trailer from the coupler.

JBarca wrote:

If we determined the snap up area failed from the chain force pulling "down" on the snap up, and the DC area pulling "up" on the cam arm, then the 2 areas of failure happened at different times and from different force directions. Agree yes/no?

I was all ready to disagree, but I see your point. So I went back and changed my story some - to discuss this twisting action with the bar pulling down in one spot on the cam and the chain out at the end.

What if the spring bar is loading the cam at the inside keeper flange, basically as far away from the chain as possible. Also assume that since it's all new and not worn in, that the bar is only contacting the cam on a small portion of the bar - at that flange. I'm stacking the deck here to see if my idea is even remotely possible. So, the bar is pressing down on one side of the cam, and the chain is resisting that force on the opposite side of the cam. This would produce a twisting force, but I don't know how much.

I don't have the bar here, or else I would get a photo to see where it's starting to wear....

Well, here goes. Until tonight I could not figure out exactly how the "up" force came to be that crushed the DC frame plate inward. I knew it had to be "up" but how??

You are correct, there is a hard down pull on the chain, we know this as it took out the snap up. So how can there be an "up" force to bend the and twist the DC frame plate up and inward? The chain connects the snap up and the DC so how can the DC lift? Well the DC is not lifting, but the force is upward into the frame.

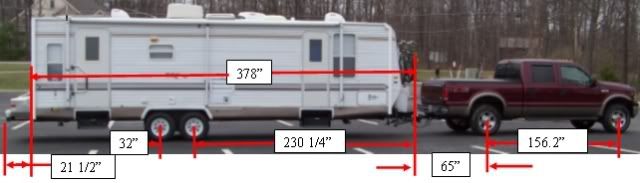

We have talked about the heavy WD bar loads that can occur on one side of the A frame and the other side unloads a lot or is at 0. The compound angle turn in addition to possibly a level of back flex in the hitch from terrain changes may creates the perfect storm that your thin A frame tube can't handle with those size WD bars and loaded TW on this setup.

The heavy force is coming from the loaded spring bar pushing down on the DC arm. So now I am starting to connect the dots on how the DC is tied to the snap up failure and how the DC frame plate crushed the frame. These 2 events which may have happened at 2 separate times or both at once.

See if this fits. The damage in your pics tell the story. Good pics by the way. We have a lot to work with.

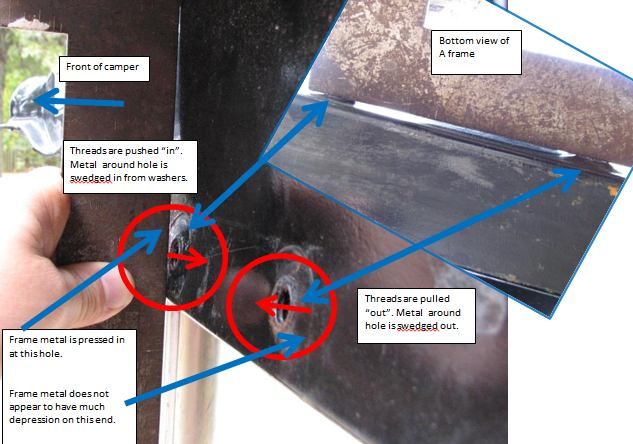

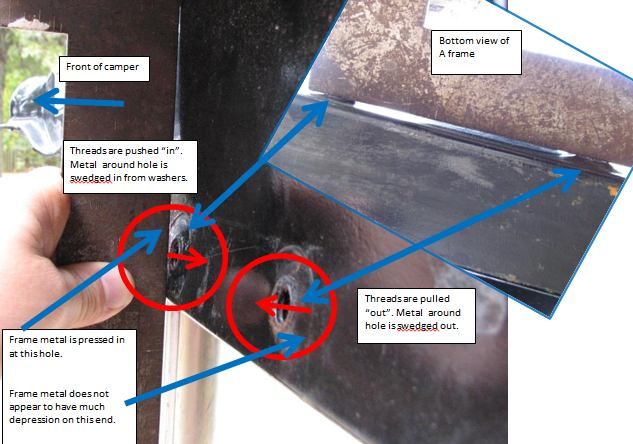

This first pic told the story of the end result of the DC arm being pushed up and rotating. Note the pic is flipped from the angle you took it. The ball coupler is to the left so we know which is the front self tapping screw hole and which is the rear.

If you look closely, the front hole closer to the ball coupler is pushed in when the DC frame plate pushed the frame in. The flat washer you had behind the frame plate left an impression and indentation in the frame when it collapsed. Yet the back hole towards the TT has the threads still pulled out and the frame is not pushed in much if any at this hole like it is on the front hole. This is confirmed by the bottom view you took. The front hole is pressed in, the rear hole swedged out from the self taping screw.

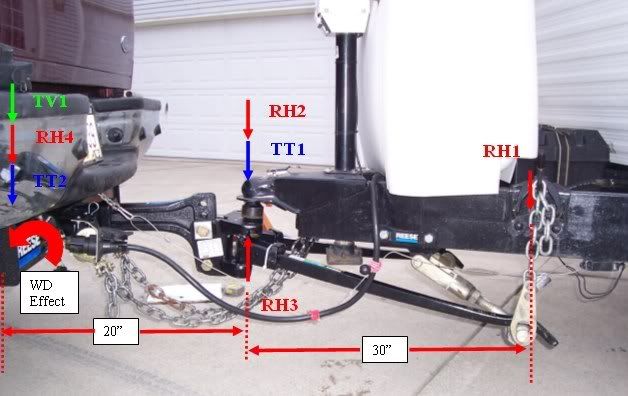

This pic mocks up a back flex where an angle is between the truck and the TT from the road surface being in 2 different planes. I could not mock up the compound angle turn in combination with this back flex with the pics I had to work with. I'm not totally sure if the back flex was a lot or not much at all. The compound angle turn alone could of done it all. The one side of the A frame, the drivers side, was under very high load from the WD bar being highly loaded pulling down on the chain. The opposite side of the A frame had a lot less.

Look at the force direction arrows. The WD bar pushes down on the DC from setting up WD. The DC pull down on the chain. When in a turn there is a force that travels up the DC arm right into the front self tapping screw on the frame. There is a force then when straight ahead too, bit "i think" it is less then when in a turn like this.

This WD bar force traveling up the cam arm into the frame is the "up" force along with a twist. That front bolt took the blunt of all the force and pressed the frame in. That action then rotated the DC frame plate and drug the locking set screw like it did.

Here is the top view. Look at the washer you have behind the front bolt. That put all the load in one spot. And now seeing this view you can envision how the DC frame plate can rotate with that heavy force coming up the DC arm stopping a the front bolt.

So, does that fit? Like I said the entire damage at both areas could of come from 1 event or 2 now that I see how the forces could move to the frame.

mrekim wrote:

JBarca wrote:

Keeping an open mind to this, after all this review is there anything else on that very short trip you made that sticks out to cause forces in the directions we are talking about? A hard bump from a pot hole etc?

I can think of two compound angle turns

One was a left out (and then back in later) the driveway.

The other was a compound angle right turn, leaving my neighborhood out onto the main street. I'm pretty sure we've done that turn a few times as well. It's not a hard angle, but the trailer is higher. If I had to pick a turn/event candidate that would be it.

When coming back we did not do the reverse (left turn) into that compound angle turn.

In light of this new realization, if it holds water that is, you will have to retrace you total trip in your mind on where did the truck riding surface create any level of back flex and did it come with a compound angle turn at the same time? We know the damage occurred on the drivers side of the TT. You or I really need to know the amount of level or uneven ground and which turn direction was the kill shot that created the high WD forces. Or there where several turn events. Pending the amount uneven ground you drove on I can build a case for a left or right turn doing this.

If I have figured this out correctly, then the higher loads connected with DC did aggravate your snap up failure. Now we are back to what is so different with your A frame then all the other DC users running a 3/4 ton truck, 1,200# WD bars with a DC and 6" tubing A Frame??

OK tell me what does not add up with my thought process?

Hope this helps

John