Hi mrekim,

I may have not used the right words about the snap ups per your response. But, I think we are on the same page, just want to clarify some points.

mrekim wrote:

JBarca wrote:

I have not yet figured out if the DC addition to the WD hitch created all this frame issue. Not that anyone is yet pointing to the DC to aggravate this frame bend at the snap up issue, just I myself have not connected those dots yet.

I believe the DC contributes to the forces attempting bend in the face of the frame.

Lets clarify. There are 2 areas a frame failure and I'm thinking they are coming from 2 different force directions and 2 different events. Here are the 2 areas.

1. The snap up area

2. The DC mounting area

What I was wondering on was, are they independent or do both need to be combined to occur? Or said another way, Is the failure of the frame at the snap up "caused" by using a DC?

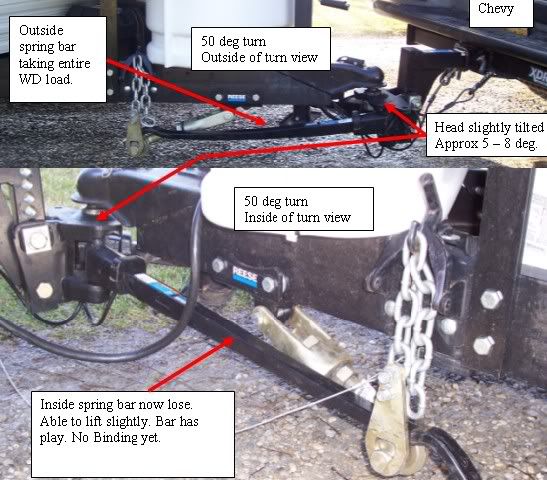

I cannot "yet" connect the dots that the DC was the cause of the snap up area failure or added to aggravating it. It "appears" the A frame snap up area failure was caused by the loads imposed by the WD pulling "down" on the chain in a compound angle turn and the frame could not handle them. This "could" of happened without a DC installed. And any of the brands of snap ups I listed "may" have produced the same effect. This will be a key point with Coachmen.

The evidence for sure points to the snap up area was caused by a "downward" force pulling on the chain. Agree, Yes/no?

mrekim wrote:

We agree there's considerable force at the bottom of the snap up. And I think we agree that it gets worse if anything goes south (snap up bends, frame bends, etc.)

Yes, we 100% agree. Yup, you got it.

Now lets go to the 2nd area, the DC frame mount. This area has something else going on. This is why I'm saying the 2 failures have different attributes to them.

mrekim wrote:

In addition, I think there's a rotational force on the dual cam mount where it wants to rotate into the face of the frame. Those self tapping screws in thin sheet metal aren't much of a deterrent.

I'm pretty sure the dual cam frame bracket rotates a little as soon as a load it applied, so some rotational force is always there, it's just a matter of how much.

Here is the set screw pic. It dawned on me from you showing this again. The set screw drug the frame and headed towards the "bottom" of the frame. In order for the dig marks to go that direction the DC arm had to be lifted "up". Agree Yes/no?

Now the frame crush at the DC frame plate. This pic aligns with the set screw rotation. The DC arm had to rotate "up" in order to crush the frame in. Both the set screw and the frame inward crush support an upward force doing this damage.

If we determined the snap up area failed from the chain force pulling "down" on the snap up, and the DC area pulling "up" on the cam arm, then the 2 areas of failure happened at different times and from different force directions. Agree yes/no?

The heavy downward chain force that collapsed the snap up area would of pulled out on the DC frame plate screws trying to rip them out of the frame, not collapse them inward.

mrekim wrote:

If my analysis is correct, then the dual cam design is "doubling down" on trying to bend the frame vs just using weight distribution with snap up bars.

Help me understand what your saying here. Double down that is.

I "believe" the DC frame area failure came from fact of the high tongue weight and a 1,200#WD bar just going straight ahead totally independent of the snap up. The turn did not kill this one.

Let me try and explain as your other comments help support this. Truck is straight ahead, both WD bars are fairly equally loaded. At this point the snap up area may be fine and resisting the chain force pulling on it as both snap ups are taking close to equal load.

Down at the DC area the chain is pulling "up" on the cam arm from the normal WD forces. This WD up force on the DC arm bent the DC frame plate into the A frame and in the process rotated the DC frame plate scraping the pinch bolt towards the bottom of the frame.

You said yourself you noticed cam arm flexing on the frame from just letting the TW down on the bars. It may have been one bump just plan going straight ahead or in a slight turn to laod one WD bar more and the bounce impact shock bent the DC area inward by pulling "up" on the chain.

This is why I think there are 2 separate events that caused the failures. The force directions to cause the failures are in opposite directions.

Bottom line, your A frame can't handle the side imposed forces of this hitch in the current configuration. The DC is unique to Reese, however the snap ups forces are common to many other brands that use a chain.

There is something for sure different about your setup. There are lot of folks with an Excursion, heavy TW campers, WD hitch with chains and even tube A frames. An unknown is the tube strength on theirs and yours. Why would yours be so much different?? That is a good question not yet understood. I knew when I saw this failed from your pics the 1st time, WOW that's a new one. Many folks have ripped out the threads of the DC frame plate from a bind in the hitch. Yours is the 1st one I recall seeing bent in. Maybe someone else can bring up another inward failure.

Keeping an open mind to this, after all this review is there anything else on that very short trip you made that sticks out to cause forces in the directions we are talking about? A hard bump from a pot hole etc?

Hope this helps

John

PS we have had other campers with Tube A frame failures, I tried to remember the guy who's entire A frame broke off at the header. I hunted for it and can't find. His camper mfg replaced the whole thing in his drive way. Pics and all of it. Was a few years ago. And then there are folks with channel iron A frames too small for the loads and they buckle the headers too. Both steel shapes can be made to work providing they are strong enough for the TW's and WD hitches needed for that TW.