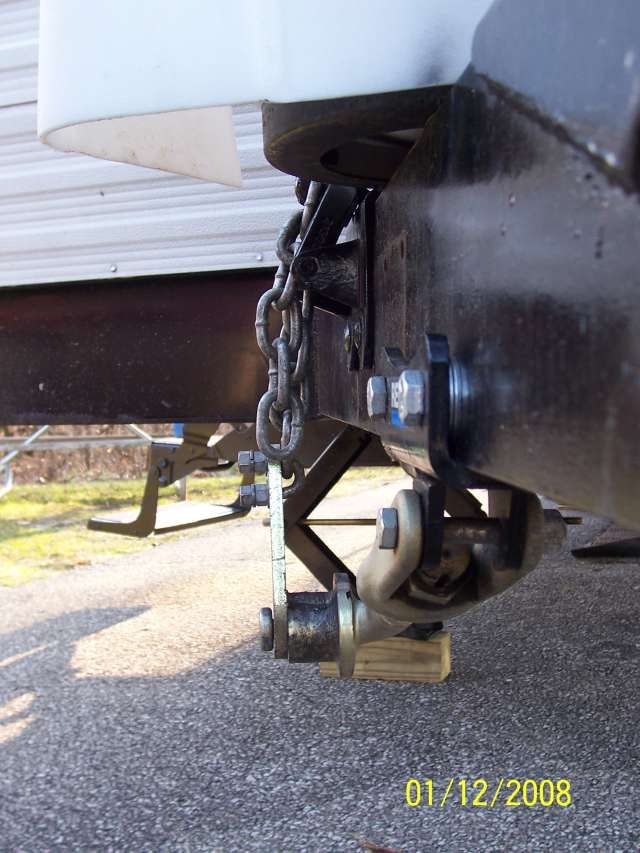

Lets look at this older style failure

Came from

here:And now yours.

There are a number of similar things going on. The set screw bend is the same or at least ended up the same. I believe that bend happened as a by product of the snap up letting go. It did not bend that hard at first, but did later in the failure.

Now what is common, both snap up's where not bolted to the frame. Both can have 1,200# WD bars and heavy tongue weights. In a compound angle turn where the truck is on angled ground in relation to the TT axles the outside WD takes "all" the load, the inside turn bar is loose just laying there doing nothing. This bar action is normal but it creates one really large load on the outside snap up bracket.

On the older style bracket the top angle laying on the frame would start to spring open, (open up more than 90 degrees, starts heading to say 95 to 100 degrees) from the heavy vertical pulling down on the chain. The snap up is also sliding "down" the frame now too as there are no through bolts to stop it. Once the bracket was pulled hard enough and you get to maybe approx 110 degrees sprung open, the chain is now hanging way out beyond the toggle locking point and not straight up and down any more. If the heavy chain load continues the set screw is straining hard to resist and starts giving way. It is now the only thing left to hang on as the snap up keeps sliding down the side of the frame and pivoting outward.

Now on yours they helped the top spread open problem by adding the gussets, but still if the chain forces are heavy enough and if the WD had any contact with the cam arm like I show in the beyond 76 degrees pics, the next weak spot is the set screw and the thin wall tube frame. It is some speculation what gave way first, did the frame start to collapse 1st and then the set screw start to bend? Or a high WD force pulling outward from beyond the 76 degree area pull down and out agaisnt the set screw?

Again in your case you do not have the snap up's bolted on. So the bolts cannot prevent the slide down the frame problem or help prevent the down and outward force of a WD bar pulling on the snap up trying to pivot outward agasint the set screw. This is even more complicated by the thin tube A frame as the support which can crush.

In my case I have the old snap up's, 1,600# loaded TW, 1,700# bars and I'm lifting a level of truck bed weight with the WD aft of the rear axle. But mine are bolted on. The bracket cannot slide down and the bolts resits any outward pull. Trust me, I turn hard. I should of killed this setup by now if it was not for the bolted on snap up's. I also have 6" standard C Channel frame and that will not colapse in like the tube frames.

Summing this up, the thinner tube frame can bow in and that flex "might" start this chain reaction. In order for the set screw to bend like that there has to be a moment load (torque) on the snap up by the chain. The force vector in the chain is not straight down.

OR

The load on the chain is high enough what little moment distance the chain is away from the frame starts pivoting on the lower ears of the snap up and pulling hard on the set screw as the top is gusseted to not spring open. Once the set screw starts to bend, all bets are off and the thing collapses.

On heavy tongue loads and strong WD bars the only way I can see to stop this the snap up cannot slide down or bow out on the frame. Once either of those actions start, it's all over. Have you ever had a C clamp fail because you over tighten it and sprung it? this set screw snap up setup uses a simialr concept.

The DC bending in, I think this "might" be a by product of the snap up failure. The snap up died first. Towing continued with a bent bracket. The chain hang is no longer vertical as the snap up is all out of kilter. In a turn somewhere after the snap up let go, the angled chain pulled on the DC arm and bent the frame "in".

OK does any of this seem to fit what you are seeing?

Hope this helps

John