- Good Sam Community

- Everything RV

- Technical Issues

- Re: 3000W Chinese Gensets Info.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

3000W Chinese Gensets Info.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-02-2005 06:20 AM

professor95 wrote:

EDIT ADDED 45/5/2013- When this thread started in March of 2005, I never expected to see it survive this long or amass the quantity of information that has been shared here.

In the eight year run of this thread we have amassed almost 10,000 postings and surpassed a million views. This creates somewhat of a dilemma for anyone who has just discovered the forum.

Since the amount of information is virtually overwhelming, I suggest you set your preferences for this thread to read "newest first" and then begin to page backwards.

What you will find in these pages is a wealth of info on virtually any make or model of Chinese manufactured synchronous (non-inverter) generator in the 3,000 watt performance class. Info will include how to rewire series coils to parallel to obtain maximum wattage from a single 120 volt outlet. Tips on further reducing sound levels, how to care for these generators, which ones are "RV ready" and provide the best overall performance for the dollar invested. Which companies NOT to deal with, where the best prices are, how to safely wire the generator into a home or RV, how to check your RV for electrical faults, sources for generator accessories, which 20/30 adapters are safe to use and which are not. How to convert a gasoline generator to propane or NG. This is only the beginning. The forum has a life of its own with the focus sub-topic switching frequently. Still, the main topic of utilizing the amazing, inexpensive Chinese gensets is always there. The amount of creativity and innovation presented in these pages is indicative of the talents shared in the diverse backgrounds of the folks who make up our combined RV community.

Many of the original brands and models of Chinese gensets mentioned in the introduction and early pages of the thread have since disappeared. New EPA and CARB emissions requirements, company bonds assuring the emissions warranty will be honored even if the company goes out of business, and fierce competition in the industry have changed the playing field. Champion Power Equipment has become the apparent "trophy team" providing an ever expanding retail outlet, an ample parts supply, a strong warranty and excellent customer service. CPE has continued to improve their product and now offers a new model (#46538) with exclusive convenience, safety and performance features aimed at the RV market. Big names like Cummins/Onan, Honda and Generac all now have Chinese built open frame synchronous gensets available. Ironically, the prices often found on these gensets has not significantly changed during the past eight years - even with the devaluation of the American Dollar and new EPA/CARB requirements.

I also encourage you to use the search function and even the advanced search options to find information. Key works such as "rewiring", "PowerPro", "Champion", "Onan Homesite", "Duropower", "ETQ", "Jiung Dong or JD", "Tractor Supply", "Costco", "Lowe's" and "Home Depot" are all examples of keywords that will give you specific information on different models being sold by retailers today.

Or, you can fill your glass with your favorite beverage (keep more close by - maybe some munchies as well :D, sit back at your computer, tell your wife (or significant other) that you will see her in the morning and spend the next 10 or so hours reading through the postings.

No one on the forum gets mad if you ask a question that is a repeat. Please do not hesitate to post to the forum. All questions are considered important and those active on the forum will do their best to respond with a valid answer.

Also note we are not out to knock the Honda, Yamaha, Kipor or other brands of high end digital gensets. We recognize the quality of these products and their suitability for quite, efficient RV use. But, there is a flood of reliable, inexpensive and comparatively lower cost gensets coming out of China that are excellent alternative choices for the RVer wanting power to run an air conditioner, microwave, etc. without excessive noise or breaking the budget.

Oh, one last thing. The folks on this forum are true gentlemen. We do not flame one another or the product discussed - period. Ugly contributors usually have their comments and remarks ignored by our masses. It is not a forum to start arguments to obtain a clear win. We do disagree on many issues, but we have all agreed to do that in a respectable manner.

We now have the introduction of more and more inverter gensets. There is a rather extensive thread named "The Official Unofficial Champion 2000i Generator" on this forum. Today, I added info on the new Champion 3100i inverter genset. Discussion on this product may get moved to its own thread at a later date.

Many have looked upon this thread with distain saying Chinese is cheap and doomed to failure. I remember saying exactly the same thing about Japanese products a few decades back. But, over the past eight years the track record for Chinese built generators has shown otherwise.

Please, join us in a fascinating journey down the Chinese built genset road of knowledge.

This is the question I posted that got it all started back in March 2005.......

Randy

For a little over a month now, I have been somewhat intrigued by the availability of a 3000 watt, 6.5 HP generator at Pep Boys and Northern Tool for under $300.00. The engine on this generator looks identical to a Honda 6.5 HP OHV engine. Knowing that the Chinese have become very adept at “cloning” reputable technologies from other manufacturers, I was not surprised at the similarities. Neither store could give me any information on the generator nor did they have a “running” display model.

I have done a little research. This is what I have discovered:

Many of these generators are imported by ELIM International (www.eliminternational.com) out of Buffalo, New York from Jiung Manufacturing in China. (The unit at Northern is identical but carries the JIUNG name.)

The engines are indeed a Chinese knockoff of the popular 6.5 HP 196cc Honda Engine. “Supposedly” Honda has licensed the engine technology to the Chinese manufacturer of the product.

The Chinese company that makes the ELM3000 generators is a rather large, diverse, long-standing company with a reputation for “above average quality” Chinese made products (Jiung Manufacturing). There are many more Chinese companies making almost identical gensets.

The generators at PepBoys do have a six month limited warranty. But, it is only on the engine (not the generator) and requires paying for shipping to and from Buffalo. Probably not a very practical thing to do if you have warranty issues.

ELIM does supply replacement parts (a PDF parts manual is available on the ELIM web site). No prices are given for replacement parts nor is there an “availability listing”.

The generator head itself is a brushless design. The only really significant wear parts in the generator are the bearings – most likely universally available.

The published dB rating is 67 at 23 feet. This is “reasonably” quite for a generator of this size as most comparabl.... The 67 dB rating is the same as Honda gives their 3000 watt CycloInverter with a “look alike” eng...

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-28-2010 06:56 AM

MrWizard wrote:

@ mrfixit

AFAIK, the Potentiometer 'Pot', adjusts the field voltage of the rotor windings, which controls the output voltage from the stator output coils

Yes. What the Wiz said.

It is a ten turn pot and you adjust it with the AVR unbolted so you can get to the pot - with the engine running. Do not make adjustments with a load attached to the generator.

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-28-2010 06:37 AM

mrfixit454 wrote:

Hey Professor... have you messed with that pot? Do you know what it adjusts?

Can we still get parts like this for the ELIM 3000 of 5 or so years ago? ELIM International seems to be around but they have different models now and I don't see parts on their website anymore.

Fixit

The "original" ELM3000 did not have an AVR like the one I showed. They used a capacitor to provide "voltage stabilization" through a different method. It was less precise and had more distortion on the AC signal as a result. Still, it was a darn good little genny!

The capacitor used in the ELM3000 are standard industrial control items. Perhaps a little more expensive in single lot replacements than a case from China, but none-the-less not some obsolete chunk of plastic.

The ELM3000 is totally inductive and used no brushes. If it sits for any considerable length of time it may require "reflashing" to generate power.

Jiang Dong built the ELM3000, thus most any similar class Chinese generator replacement parts will interchange such as air filters, ignition coils, governor assemblies, transition (shut down) modules, recoil starter, motor mounts, switches, meters, carburetors, etc. Components within the alternator are different from current models and would require a visit to an electric motor rewinding/repair facility to get them fixed.

In the past, CPE has been willing to sell parts from their models for use on other Chinese generators and DuroPower has an extensive listing on their web site as well. Northern Tool can also supply matching parts under their PowerHorse brand. I believe you will find that many small engine repair shops that shunned the Chinese GX type clone engine market a few years back are glad to have their business now.

You may have to be moderately resourceful, but there is no reason you can't keep that old ELM3000 running for many years to come even if Eliminator no longer supports the product.

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-28-2010 06:00 AM

A number of AVR failures has not included the Champion C46540 in the genhouse. Been overheated many times, tho' a record was not logged. As for the cause, I do believe, if there was a 'known', we might avoid a repeat. Not saying the three possible causes you list should not be included in the 'caution list'. I refuse to discontinue my quest for a cheap fix to the noise issue. The 3500w Chinese open frame Gensets are, to me, a real value buy. Champion seems to be the high volume leader and with the new Models, well kudos. But, there are others with good reports. Some with AVR failures. I will not allow those failures to be my worst enemy. Noise is the enemy. Near a victory with my latest semi-enclosure. I remain convinced something can be added to aid in the quest for sound lowering. Maybe a SuperGen/Gentent? I do like Yellow and Black.:)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-27-2010 09:56 PM

AFAIK, the Potentiometer 'Pot', adjusts the field voltage of the rotor windings, which controls the output voltage from the stator output coils

But I Can Not understand it for you !

....

Connected using T-Mobile Home internet and Visible Phone service

1997 F53 Bounder 36s

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-27-2010 09:38 PM

Can we still get parts like this for the ELIM 3000 of 5 or so years ago? ELIM International seems to be around but they have different models now and I don't see parts on their website anymore.

Fixit

2006 2500 Dodge Ram Megacab, Cummins, Auto.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-27-2010 07:56 PM

Old & Slow wrote:

Well s*** happens. I have not the slighest idea about what is inside the AVR. I had one go out on an OEM Onan with less than three hundred hours. There have been numerous AVR failures on the 3500w Chinese gensets reported.

Floyd

Floyd,

There have been "a few" AVR failures reported. Considering the number of units we are encountering from folks on this thread my take is it is no more per 1,000 units than any other electronically controlled appliance - such as a TV or DVD.

I will go on to say that it looks like the majority of AVR failures can be attributed to:

- Excess heat

- Not shedding a load before shut-down

- Starting the genny under load

I have experienced two AVR failures. One was due to my initial ignorance of proper care and feeding of a new generator and the other was intentionally pushing it to excessive temperature limits to discover what an AVR could withstand. John was conducting a similar test when his auxiliary cooling fans shut down on an enclosure he has built.

The AVR's in Chinese generators contain an array of diodes and transistors, not to mention the expected resistors and capacitors. The most susceptible component appears to be an IRF830 PowerMESH MOSFET. A photo of an AVR I un-potted is shown below. As you can see, it contains a lot of "stuff".

The so called problem is not unique to any particular brand of Chinese generator. They all use similar AVR's.

I would just hate for anyone to get the idea that these things were dropping like flies. While failures do occur, they are NOT numerous.

Unfortunately, when a failure does occur the voltage spikes to 180+ and anything connected usually gets fried. This is why CPE now has OVP as a standard component in their newer generators and owners with older or different models may want to consider an axillary plug-in OVP device as added insurance.

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-26-2010 11:07 AM

Never say never. Or, tried and proven.:) Just the other day, I went out the the genhouse to work on yet another enclosure mod' and discovered I have a oil leak. What's next?

One comment, my thinking is the opening to the genhead can be off set.

Just today I built out of hardboard (using the cover for a templete) a duct that will do just that. Got to make noise turn a corner. Must seperate cool incoming air (to the genhead) from the engine fan, air blowing out the genhead end. This is the most difficult issue to deal with in building any enclosure. My efforts have covered a three year span.

Floyd (O&S)

John,

I'll not add any fans for now. Maybe you are saying the PC/server fans may have stopped running and impeded the air flow?? Or just impeded the air flow, period. Hey John, your talents and skills show well with the fabrication of the vent. I believe your home built flying machine was easy on the eyes and was a winner. Please keep us updated with all future developments with the retro DuroPower project.

Floyd

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-26-2010 09:29 AM

This is a critical issue. Simple solutions have been to remove the AVR and simply extend the wiring harness so it is "outside the box". Unfortunately, this does nothing to boost the air flow across the innards of the alternator.

While it may look crude, the coffee can and metal duct tape approach with a conventional 12 Volt or 120 VAC "muffin fan" in the end of the coffee can has proven to work well for additional air flow. The muffin fans are normally square corner, which can be cut off so the fan fits inside the coffee can.

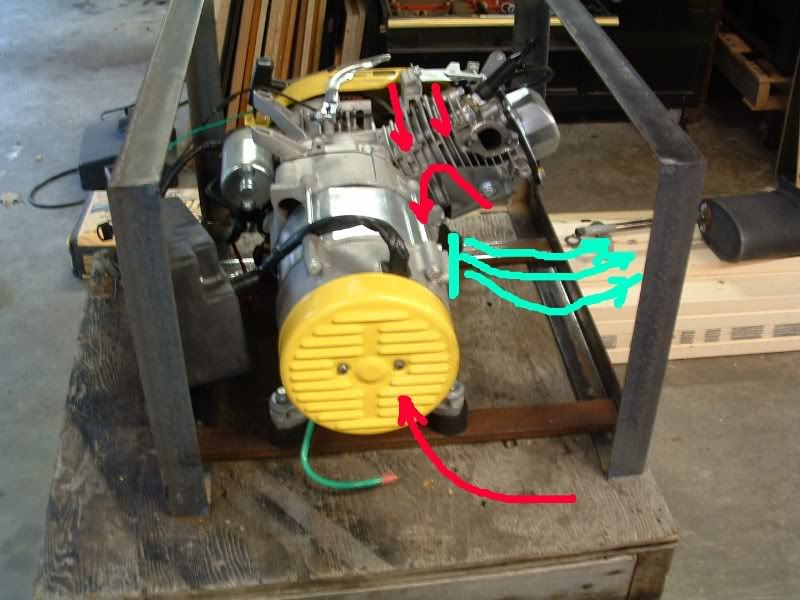

The first photo below shows the open end of an alternator and the AVR sitting in front.

Photo #2 is a typical AVR

Number 3 shows how the simple coffee can cooler is assembled and attached.

The last photo is a surplus ROUND fan that is perfect for the alternator - finding the right size takes a little searching on the surplus web sites.

Lastly, and since my photo library is open so I can grab images easily, one must respect the design air flow of the OEM generator. The photos below show that airflow pattern. Do NOTHING to alter this air flow pattern - if possible augment it with fans to assure adequate air movement.

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-26-2010 08:17 AM

jlaustin wrote:

I've had zero problems with the genset ever since.:B

I went out yesterday p.m. to do some more testing, and unbelieveably, had what I believe was an alternator cooling duct fan failure(my mod - obviously not DuroPower's fault) that probably led to an AVR failure! Until I get a chance to pull the duct and check out the fans, I would caution anyone considering my pressurized cooling duct for the alternator to "go slow" and wait until I pinpoint exactly what happened.

More later!

Regards,

John

2005 Pilgrim 274RL-5SS

2008 F-250

Amelia - the Welsh Terrier. Daisy, Bonny, & Rosie - the cats!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-25-2010 05:21 PM

jlaustin wrote:joelchappell wrote:

I am working on my generator compartment and controls for the mystery generator that I will eventually get and I have a question for those who have gone before.

Do you monitor the compartment temp for fan control, or do you place your sensor on the cylinder head? I have a thermistor to control a 10" 650 cfm fan to pressurize the compartment, but I am debating where to control the fan from.

I think I would rather monitor the compartment temp so the fan would come on before the cylinder head temp rose too high.

What are your thoughts?

Joel,

The Professor has extensive experience with enclosed compartments and can best address your question, BUT, I "torture tested" my DuroPower 3500ES which is sort of a hybrid - partially enclosed frame, open bottom. I found that the alternator temp inexorably rose from continuously running the 15K BTU A/C no matter what other cooling/ventilation was available. It usually took about an hour to get to 190 degrees on the alternators exhaust - a worrisome temp as the Professor suggests the core is even hotter and most of the insulation is rated for higher (260 as I recall), but the rating is under ideal open-air conditions - not what is going on deep inside the alternator!

I put a gang of 4 25+ cfm computer server fans in the alternator's intake duct I fabricated for 100+ cfm total ( cost every bit of $9.95!!!). They are designed to provide moderate pressurization of computer servers. With this setup, the alternator stays at about 150 degrees no matter the ambient temp, humidity, load, etc. In fact, I put a temp switch on the alternator exhaust that kicks in at about 150 - the cooling fans are able to cool down the alternator so much so that they frequently cool the switch down to below 150 and turn off! Another benefit is the first thing the pressurized duct's flow hits is the AVR - doesn't hurt to keep that cool, too!

I would suggest some sort of similar arrangement and then monitor cylinder temperature at least initially to be sure the engine's fan is "keeping its cool". As I said, the Prof can add more insight to that area. Since my setup is semi-open frame (open bottom, 500 cfm ventilation fan above), I've "assumed" the engine can cool itself - I'll be checking some infrared temps on the engine to be sure - need to paint a dark spot on the cylinder to aim the infrared thermometer.

Regards,

John

(BTW - I'm about 30 minutes south of Crossville which is 30 minutes east of Cookeville. I'll be back from Oshkosh/AirVenture August 1st, so feel free to come by and check out my setup after you get your parents settled in Cookeville! You can PM me for directions, etc.)

Thanks for the input. I studies your Case fan array. It is interesting to me how well they work.

Not sure exactly in August when I will be through there, but I may take you up on it.

Loated in Sunny Florida

2006 Roadmaster Predator

1970 VW Westfalia Daycamper

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-25-2010 04:49 PM

I have some of the same questions concerning the genhead air intake. I needed to go back 7/14 pages to find the post by John showing the quad fan installation. John, if you will, please give us the size of the fans. No doubt, in the new enclosure now being built, the additional fans will be needed. The volume of exhaust air under the genhead has previously caused a doubt in my mind if additional added fans are needed, but, I could be building the duct now. Back to live and learn.

John,

You do know how to hurt this old man. Going to Oshkosh/Air Venture ~ can only dream, here in Texas.

Floyd

Oh, Ryan,

Keep us posted on the repairs, how many hours on the new Champ?.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-25-2010 03:52 PM

joelchappell wrote:

I am working on my generator compartment and controls for the mystery generator that I will eventually get and I have a question for those who have gone before.

Do you monitor the compartment temp for fan control, or do you place your sensor on the cylinder head? I have a thermistor to control a 10" 650 cfm fan to pressurize the compartment, but I am debating where to control the fan from.

I think I would rather monitor the compartment temp so the fan would come on before the cylinder head temp rose too high.

What are your thoughts?

Joel,

The Professor has extensive experience with enclosed compartments and can best address your question, BUT, I "torture tested" my DuroPower 3500ES which is sort of a hybrid - partially enclosed frame, open bottom. I found that the alternator temp inexorably rose from continuously running the 15K BTU A/C no matter what other cooling/ventilation was available. It usually took about an hour to get to 190 degrees on the alternators exhaust - a worrisome temp as the Professor suggests the core is even hotter and most of the insulation is rated for higher (260 as I recall), but the rating is under ideal open-air conditions - not what is going on deep inside the alternator!

I put a gang of 4 25+ cfm computer server fans in the alternator's intake duct I fabricated for 100+ cfm total ( cost every bit of $9.95!!!). They are designed to provide moderate pressurization of computer servers. With this setup, the alternator stays at about 150 degrees no matter the ambient temp, humidity, load, etc. In fact, I put a temp switch on the alternator exhaust that kicks in at about 150 - the cooling fans are able to cool down the alternator so much so that they frequently cool the switch down to below 150 and turn off! Another benefit is the first thing the pressurized duct's flow hits is the AVR - doesn't hurt to keep that cool, too!

I would suggest some sort of similar arrangement and then monitor cylinder temperature at least initially to be sure the engine's fan is "keeping its cool". As I said, the Prof can add more insight to that area. Since my setup is semi-open frame (open bottom, 500 cfm ventilation fan above), I've "assumed" the engine can cool itself - I'll be checking some infrared temps on the engine to be sure - need to paint a dark spot on the cylinder to aim the infrared thermometer.

Regards,

John

(BTW - I'm about 30 minutes south of Crossville which is 30 minutes east of Cookeville. I'll be back from Oshkosh/AirVenture August 1st, so feel free to come by and check out my setup after you get your parents settled in Cookeville! You can PM me for directions, etc.)

2005 Pilgrim 274RL-5SS

2008 F-250

Amelia - the Welsh Terrier. Daisy, Bonny, & Rosie - the cats!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-25-2010 03:25 PM

Do you monitor the compartment temp for fan control, or do you place your sensor on the cylinder head? I have a thermistor to control a 10" 650 cfm fan to pressurize the compartment, but I am debating where to control the fan from.

I think I would rather monitor the compartment temp so the fan would come on before the cylinder head temp rose too high.

What are your thoughts?

Loated in Sunny Florida

2006 Roadmaster Predator

1970 VW Westfalia Daycamper

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-25-2010 02:46 PM

quabillion wrote:

update on my champ.

I removed the head and found alot of carbon buildup on both the head and piston.

I cleaned this off the best I could with a brush and carb cleaner, the valves were also removed and cleaned and the seats. No obvious pieces were blocking the valve from seating. Once I reassembled the engine it will sputter but still not run.

I think I am on the right track here but must have failed to remove the carbon well enough, or did a bad job of reassembly, I dont know, but will keep trying.

OK Ryan... Leave the new Mrs. alone long enough to screw a compression gauge into the Champs spark plug hole. Remember you have a compression release built into the engine that slightly holds the exhaust valve open while cranking - so you are going to need to spin the recoil pretty fast to get a good reading.

Have you done a spark test? If the ignition is OK will it run with a shot of starting fluid for more than a sputter? Did you check the low oil shutdown circuit for a stuck float?

Me thinks you must have other things on your mind -- the troubleshooting approach you are sharing is not what I expect from the Ryan I know 😉 Marriage can really change a man.

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-25-2010 01:24 PM

I removed the head and found alot of carbon buildup on both the head and piston.

I cleaned this off the best I could with a brush and carb cleaner, the valves were also removed and cleaned and the seats. No obvious pieces were blocking the valve from seating. Once I reassembled the engine it will sputter but still not run.

I think I am on the right track here but must have failed to remove the carbon well enough, or did a bad job of reassembly, I dont know, but will keep trying.