Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

- Good Sam Community

- Groups

- Motorhome Group

- Forum

- Re: My cheap solution to a worn Fleetwood main doo...

Options

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

My cheap solution to a worn Fleetwood main door

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-13-2017 12:29 PM

I bought a 2000 Southwind with a worn door hinge, it drug on the bottom and had nade a gouge on the aluminum at the boton of the opening, was hard to close and the striker couldn't be adjusted to the door wear. The striker was holding up the door when it was closed. I located the new hinges but the price for all 3 was beyond what I wanted to pay, close to $500 for 3 rebuidable hinges. I made this to fix the door and raise it 1/10" on the hinges to compensate for the wear it took 100,000 miles of use to cause.

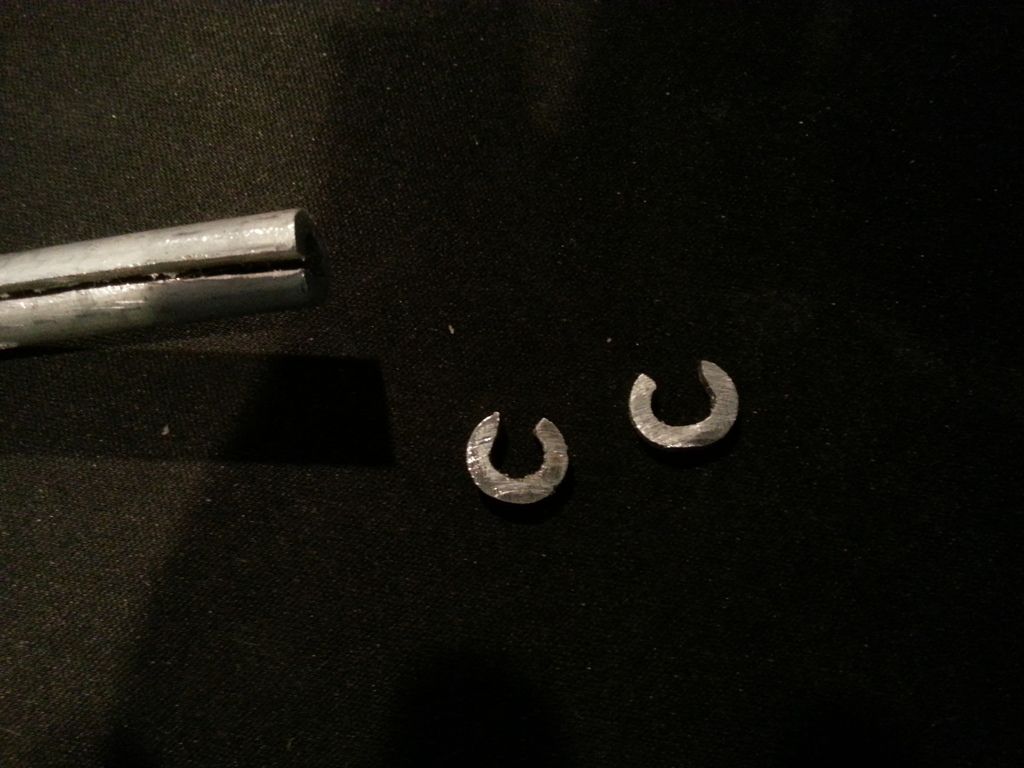

These pieces of aluminum are made of 3/8" aluminum rod I bought at Ace hardware. I cut off 12" piece and drilled a 3/16 hole in the center on a lathe. I cut a 1/16" slot in the bar over the drilled hole. I measured the wear on my hinge by lifting my door after lubricating it with sliicone spray and used calipers on the gap on the hinge. it measured 1/10 of a inch. I used a hacksaw to cut 1/10" off the drilled and slotted aluminum rod. Then I used a dull chizzel in the slot to open it to the hole size so it would fit around the hinge pin on the door, 3/16". Lift the door, raise the steel washer and insert the aluminun piece around the hinge pin so it raises the door 1/10", it takes 2 aluminun c's per hinge to raise both the screen and the door. Filing on the C pieces will help them fit if their a little off size or the gap is too small to fit around the pin. It's important to not mark the inside back of the C with the chizzle, it can make it crack. After each C is in place, use needle nose pliers to squeeze the gap closed so it can't fall out.

After you insert the C pieces and have them crimped in place, you will likely have to readjust the striker so it hits in the canter of the latch when the door closes and latches. If your hinge is cracked or the door is broken, this won't work.

These pieces of aluminum are made of 3/8" aluminum rod I bought at Ace hardware. I cut off 12" piece and drilled a 3/16 hole in the center on a lathe. I cut a 1/16" slot in the bar over the drilled hole. I measured the wear on my hinge by lifting my door after lubricating it with sliicone spray and used calipers on the gap on the hinge. it measured 1/10 of a inch. I used a hacksaw to cut 1/10" off the drilled and slotted aluminum rod. Then I used a dull chizzel in the slot to open it to the hole size so it would fit around the hinge pin on the door, 3/16". Lift the door, raise the steel washer and insert the aluminun piece around the hinge pin so it raises the door 1/10", it takes 2 aluminun c's per hinge to raise both the screen and the door. Filing on the C pieces will help them fit if their a little off size or the gap is too small to fit around the pin. It's important to not mark the inside back of the C with the chizzle, it can make it crack. After each C is in place, use needle nose pliers to squeeze the gap closed so it can't fall out.

After you insert the C pieces and have them crimped in place, you will likely have to readjust the striker so it hits in the canter of the latch when the door closes and latches. If your hinge is cracked or the door is broken, this won't work.

2000 F53 Southwind 32v

Labels:

- Labels:

-

Class A

6 REPLIES 6

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-14-2017 12:28 PM

Really really like it. Home made fixes are the best, especially when they seem better than stock.

4 whopping cylinders on Toyota RV's. Talk about great getting good MPG. Also I have a very light foot on the pedal. I followed some MPG advice on Livingpress.com and I now get 22 MPG! Not bad for a home on wheels.

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-13-2017 09:26 PM

96Bounder30E wrote:

I tried "c" clips on my door but they didn't last long... They kept spitting out of the hinges

I know the rebuildable hinges are expensive.... But they are nice...

these are crimped in and 1/10" thick, not a spring Cer-clip not this

but this that crimps on the pin with pliers

but this that crimps on the pin with pliers

2000 F53 Southwind 32v

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-13-2017 09:06 PM

I tried "c" clips on my door but they didn't last long... They kept spitting out of the hinges

I know the rebuildable hinges are expensive.... But they are nice...

I know the rebuildable hinges are expensive.... But they are nice...

Eric

96 Bounder 30E-F53(460)

stock Ford intake w/K&N air filter

used Thorley headers

new Banks resonator, muffler, tail pipe and 4" polished SS exhaust tip

96 Bounder 30E-F53(460)

stock Ford intake w/K&N air filter

used Thorley headers

new Banks resonator, muffler, tail pipe and 4" polished SS exhaust tip

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-13-2017 05:16 PM

I did basically the same thing with my door using copper washers and cutting the opening with dikes then squeezing the washers around the pin. I did this about 6 years ago and it is still holding the door in place. Mine is a 1996 with 107k miles.

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-13-2017 01:50 PM

Nice job. Thanks for posting.

When I read the title of your post I was expecting a 'Cousin Eddy' type door replacement. :B

When I read the title of your post I was expecting a 'Cousin Eddy' type door replacement. :B

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-13-2017 12:52 PM

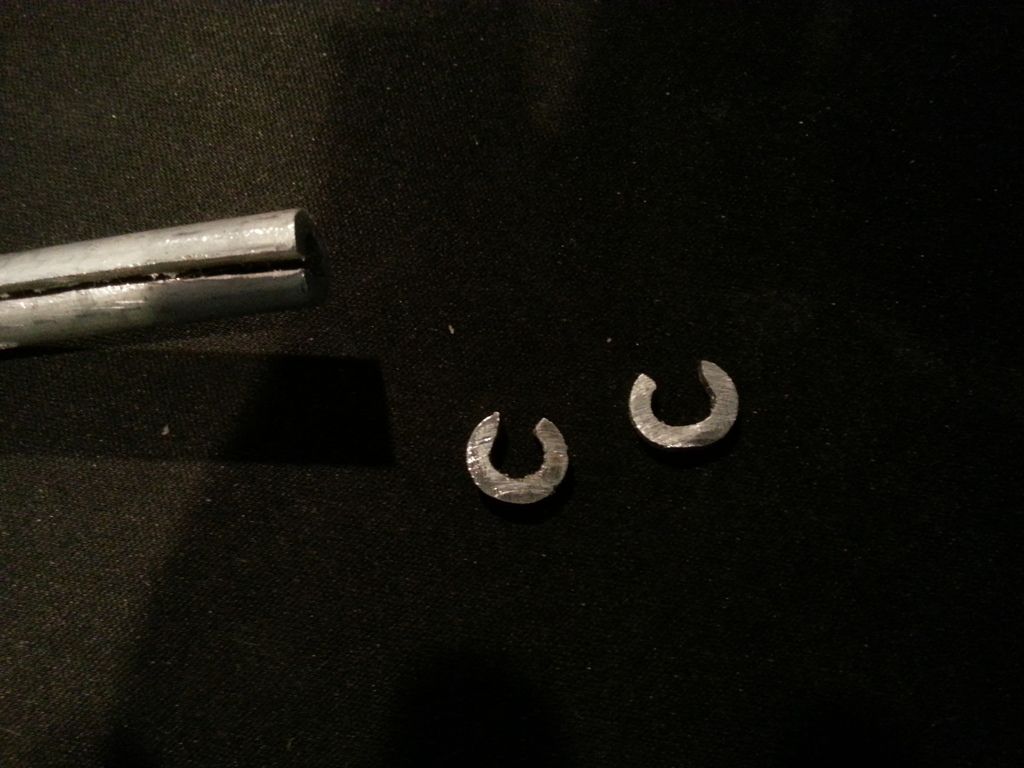

My door with the C pieces installed

2000 F53 Southwind 32v