Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

- Good Sam Community

- Everything RV

- Technical Issues

- Bent Main Frame Rail Below Slide - (Picture Heavy)

Options

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Bent Main Frame Rail Below Slide - (Picture Heavy)

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-04-2017 07:18 AM

Hello Fellow Campers,

I’m inquiring if you or someone you know has run into where the main frame rail (thin I beam style) bent down behind the rear spring hanger and if you know any of the details surrounding it? This is a somewhat technical & long post by it's nature and I will try to keep it short as I can and use pictures get the point across. I have searched the web for this type of failure and to date have not found this type of issue. I have found a lot of bent A Frames, spring hangers and I beam web cracks. Mine is different. I did find one where the frame did failed in a similar manner and it was here on RV.net. See here. Bent Frame and breaks However in this case, the camper was in an accident where the camper become air born, dropped down hard on the road and bent the frame rail in one very large event.

Background: This past fall on our last campout, our slide room would no longer retract without heavily binding on the top rear and lower front sides of the slide. This issue has been ongoing for several years and has progressed worse over time. Basically, the slide opening in the camper wall is out of square in relation to the square slide room. In the past I could fudge the slide adjustment to get the system to work. I am now out of the adjustment.

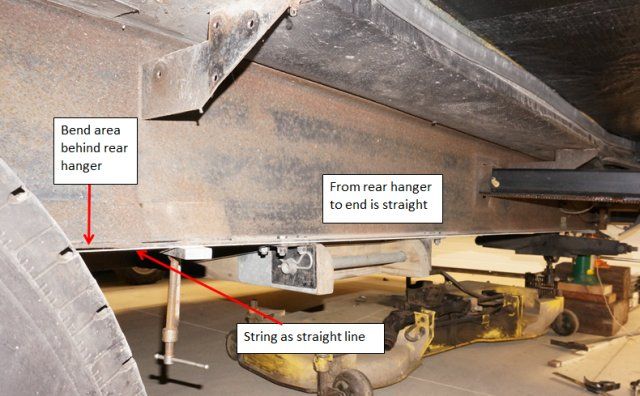

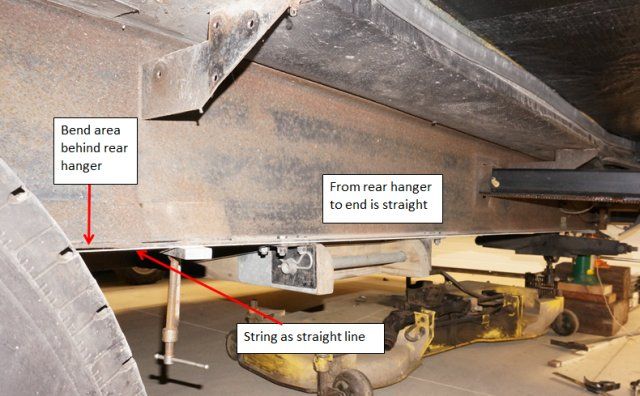

After measuring the camper, I found the main frame rail below the slide is bent down just aft of the rear axle spring hanger. By pulling a string along the bottom of the frame, starting at the front spring hanger all the way to the rear camper wall, the area between the spring hangers is straight. There is a bend down aft of the rear hanger and then the frame is straight all the way to the back wall. If I jack up the slide side frame rail at the end of the frame 3”, the bottom of the frame is now straight and the slide opening is back to true square.

We bought the camper in Oct, 2007 and I have pictures documenting several upgrades over the years to the running gear. Added new axles to correct axle alignment, added; shocks, rubber equalizer, hanger stiffeners, self-adjusting brakes and 15 to 16” LT tire upgrade. Through these pictures I can see when the frame lower flange was straight and when deformation started.

During the summer of 2010, we were towing across NY state on I-88 heading west out of the Amsterdam area into Corning NY. The state had started resurfacing from the eastern end heading west, however the last 15 miles was still old road. That last 15 miles was old concrete road and brutal with pot holes. We were somewhat trapped having to stay with in the right lane with no exits until we got off. Passing semis/cars etc. in the left lane and It was pot hole after pot hole. I slowed to 45 to 50mph and dodged the pot holes I could and not create a speed hazard on the road. When we made it to camp, the inside of the camper was the worst shaken up ride we have ever had. At this time, I had no idea the frame may have been affected.

I have pictures months before our summer trip showing the frame was not yet deformed. By the end of 2010, the pictures were showing that lower flange deformation had started just I did not realize what it meant. After the event, we did a large quantity of normal towing which went on for the next 6 years but none with a pot hole cluster like I-88. The slide opening problem started around 2010 and become worse over time. At this point in my investigation, I feel the I-88 towing event started the lower flange deformation on the slide side frame rail and slowly over time continued to increase the frame rail bend downward making the slide opening out of square issue worse.

If you have seen this type of frame deformation before and have any details to it, please pass along. This is also a learning post that if you have the thin I beam type of frame, if you ever see any flange deformation, even slight damage, that is the sign of a problem. If I knew then what I know now, I could of corrected the issue much simpler back in 2010. I have a lot more information and can share if needed.

Here are pictures of the problem.

This first pictures are “before” the problem. Notice the gap between the slide flange and the camper flange. It is parallel like it should be. These pics are from the year we bought the camper.

This is the lower flange behind the rear left frame hanger. Notice there is no distortion of the lower flange.

Now a few pics of time line leading up to current day. No damage yet in these pics.

2-8-2009 no damage

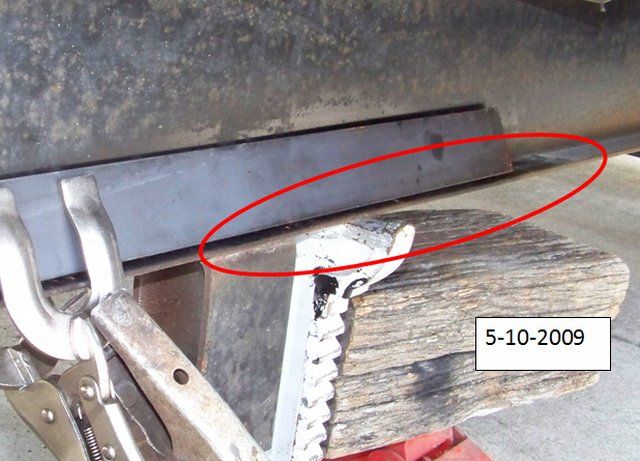

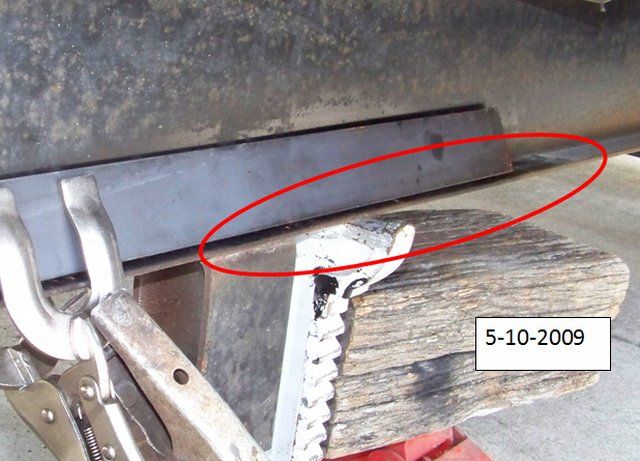

5-10-2009 adding reinforcement to prevent hanger flexing and lower flange bending and web cracking. No frame damage

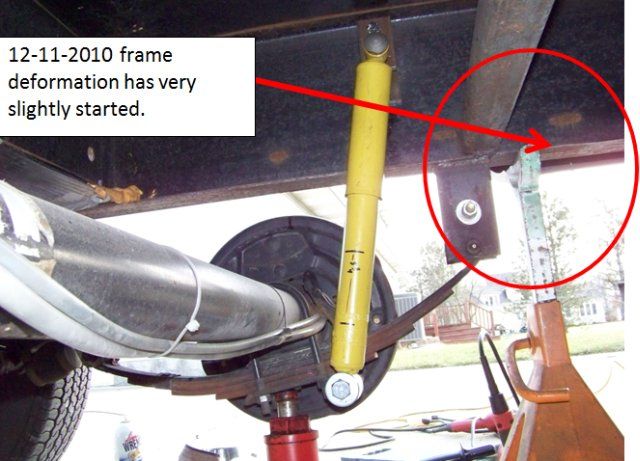

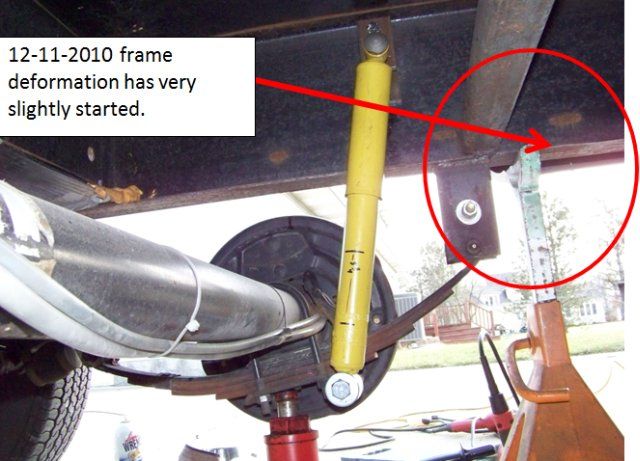

Now the start of damage. Picture taken on 12-11-2010 when adding rear shocks

4-15-2012. Top rear of slide. Gap 3/4"

4-15-2012. Top front of slide. Gap 1 1/8" Must adjust slide arms to shift slide to fit camper hole better. This creates a situation inside were we do not lift off the carpet as much

More on the next reply.

I’m inquiring if you or someone you know has run into where the main frame rail (thin I beam style) bent down behind the rear spring hanger and if you know any of the details surrounding it? This is a somewhat technical & long post by it's nature and I will try to keep it short as I can and use pictures get the point across. I have searched the web for this type of failure and to date have not found this type of issue. I have found a lot of bent A Frames, spring hangers and I beam web cracks. Mine is different. I did find one where the frame did failed in a similar manner and it was here on RV.net. See here. Bent Frame and breaks However in this case, the camper was in an accident where the camper become air born, dropped down hard on the road and bent the frame rail in one very large event.

Background: This past fall on our last campout, our slide room would no longer retract without heavily binding on the top rear and lower front sides of the slide. This issue has been ongoing for several years and has progressed worse over time. Basically, the slide opening in the camper wall is out of square in relation to the square slide room. In the past I could fudge the slide adjustment to get the system to work. I am now out of the adjustment.

After measuring the camper, I found the main frame rail below the slide is bent down just aft of the rear axle spring hanger. By pulling a string along the bottom of the frame, starting at the front spring hanger all the way to the rear camper wall, the area between the spring hangers is straight. There is a bend down aft of the rear hanger and then the frame is straight all the way to the back wall. If I jack up the slide side frame rail at the end of the frame 3”, the bottom of the frame is now straight and the slide opening is back to true square.

We bought the camper in Oct, 2007 and I have pictures documenting several upgrades over the years to the running gear. Added new axles to correct axle alignment, added; shocks, rubber equalizer, hanger stiffeners, self-adjusting brakes and 15 to 16” LT tire upgrade. Through these pictures I can see when the frame lower flange was straight and when deformation started.

During the summer of 2010, we were towing across NY state on I-88 heading west out of the Amsterdam area into Corning NY. The state had started resurfacing from the eastern end heading west, however the last 15 miles was still old road. That last 15 miles was old concrete road and brutal with pot holes. We were somewhat trapped having to stay with in the right lane with no exits until we got off. Passing semis/cars etc. in the left lane and It was pot hole after pot hole. I slowed to 45 to 50mph and dodged the pot holes I could and not create a speed hazard on the road. When we made it to camp, the inside of the camper was the worst shaken up ride we have ever had. At this time, I had no idea the frame may have been affected.

I have pictures months before our summer trip showing the frame was not yet deformed. By the end of 2010, the pictures were showing that lower flange deformation had started just I did not realize what it meant. After the event, we did a large quantity of normal towing which went on for the next 6 years but none with a pot hole cluster like I-88. The slide opening problem started around 2010 and become worse over time. At this point in my investigation, I feel the I-88 towing event started the lower flange deformation on the slide side frame rail and slowly over time continued to increase the frame rail bend downward making the slide opening out of square issue worse.

If you have seen this type of frame deformation before and have any details to it, please pass along. This is also a learning post that if you have the thin I beam type of frame, if you ever see any flange deformation, even slight damage, that is the sign of a problem. If I knew then what I know now, I could of corrected the issue much simpler back in 2010. I have a lot more information and can share if needed.

Here are pictures of the problem.

This first pictures are “before” the problem. Notice the gap between the slide flange and the camper flange. It is parallel like it should be. These pics are from the year we bought the camper.

This is the lower flange behind the rear left frame hanger. Notice there is no distortion of the lower flange.

Now a few pics of time line leading up to current day. No damage yet in these pics.

2-8-2009 no damage

5-10-2009 adding reinforcement to prevent hanger flexing and lower flange bending and web cracking. No frame damage

Now the start of damage. Picture taken on 12-11-2010 when adding rear shocks

4-15-2012. Top rear of slide. Gap 3/4"

4-15-2012. Top front of slide. Gap 1 1/8" Must adjust slide arms to shift slide to fit camper hole better. This creates a situation inside were we do not lift off the carpet as much

More on the next reply.

2005 Ford F350 Super Duty, 4x4; 6.8L V10 with 4.10 RA, 21,000 GCWR, 11,000 GVWR, upgraded 2 1/2" Towbeast Receiver. Hitched with a 1,700# Reese HP WD, HP Dual Cam to a 2004 Sunline Solaris T310R travel trailer.

33 REPLIES 33

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-04-2017 08:18 AM

Welcome to the RV World.

Everything is build to minimum standarts unless you can afford bus conversion.

That said, this bend doesn't look like coming from load stress.

More like hitting something or wrongly positioned jack.

I think jacking frame straight and welding plate to close I into square tubing would be the best reinforcement.

Everything is build to minimum standarts unless you can afford bus conversion.

That said, this bend doesn't look like coming from load stress.

More like hitting something or wrongly positioned jack.

I think jacking frame straight and welding plate to close I into square tubing would be the best reinforcement.

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-04-2017 07:43 AM

Do you know if you have a LCI(Lippert) Frame? Odds are you do. Lippert gets the blame when the Frame is not built correctly. Not large enough gauge steel and inadequate outriggers and brace supports. LCI builds the chassis to the OEM engineers specs, NOT what LCI engineers it. I have seen (Master tech) dozens of LCI frames that do what yours is doing over the years. The problem is, they do NOT build the frame strong enough for the Hole cut out for the slide room. That causes the type flex you have experienced. usually we take a frame flex measurement and then (under warranty) LCI sends a mobile crew out and they weld and install gussets(anything that is needed), to align the frame and reinforce it to get it to specs. Usually what causes the customer to notice the problem is when they have numerous issues with the operation of the slide room. It sticks/jams/ will not go in and out correctly. You are obviously out of any frame warranty. IF LCI, I would contac them and see if you could transport the RV to Elkhart, Indiana for them to fix(you would have to pay for them to do this), or how much they would charge to send one of their mobile frame repair trucks to you to fix. Without having the specific training and knowledge the LCI Frame techs have, you will have a hard time fixing it yourself. Doug

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-04-2017 07:20 AM

To help prove that the frame is the issue with the slide, I lifted the back left of the frame rail 3” and the slide opening now comes back to being parallel with the slide.

This square head is adjusted to the current condition. See the gold siding area as a line of reference to the square head (the black thing). This is the current out of parallel condition.

Now raise the frame 3” at the rear

And here is the top of the camper and the slide.

Roof line straight again - front to back

From from the back looking forward

Camper frame now straight across the bend area

The rear bottom slide flange area. Slide wall to camper flange: 2 3/4"

The rear top slide flange area. Slide wall to camper flange: 2 7/8" Only an 1/8” difference now.

So this shows the problem.

This problem may be hard to believe, but sometime late 2009 to mid-2010 the main frame rail was compromised with the lower flange starting to buckle and deflect behind the rear spring hanger. That was the beginning. Very subtle, but it started. Then over time, the bend and buckle slowly kept increasing from normal towing and frame flex. We call this “ratcheting” in the engineering world speak, sort of like bending a paperclip back and forth until it breaks. The trip mid 2010 across NYS on I-88 heading west to Cowanesque lake south of Corning NY I feel was the event that started this.

The slide side of this floor plan is heavier than the door side. This is a rear living floor plan. See here

The camper when fully loaded with fresh water and WD is engaged has these weights. The camper is loaded close to capacity but not over.

• 1,600# tongue weight

• 4,340# front axle (the weight distribution hitch force lands mainly on the front axle and the fresh tank is over the front axle)

• 4,040# rear axle

----------

9,980# GVW. My GVWR is 10,000# So I'm at the limit when I haul my 42 gallons of fresh water and we do often.

The frame rails are 10” x 9lb per foot thin I beam style or known as an MH beam. (Manufactured Housing)

The frame steel aligns with ASTM A529-50 High Strength Low Carbon Steel and responds in a bending test to be that steel.

Thanks

John

This square head is adjusted to the current condition. See the gold siding area as a line of reference to the square head (the black thing). This is the current out of parallel condition.

Now raise the frame 3” at the rear

And here is the top of the camper and the slide.

Roof line straight again - front to back

From from the back looking forward

Camper frame now straight across the bend area

The rear bottom slide flange area. Slide wall to camper flange: 2 3/4"

The rear top slide flange area. Slide wall to camper flange: 2 7/8" Only an 1/8” difference now.

So this shows the problem.

This problem may be hard to believe, but sometime late 2009 to mid-2010 the main frame rail was compromised with the lower flange starting to buckle and deflect behind the rear spring hanger. That was the beginning. Very subtle, but it started. Then over time, the bend and buckle slowly kept increasing from normal towing and frame flex. We call this “ratcheting” in the engineering world speak, sort of like bending a paperclip back and forth until it breaks. The trip mid 2010 across NYS on I-88 heading west to Cowanesque lake south of Corning NY I feel was the event that started this.

The slide side of this floor plan is heavier than the door side. This is a rear living floor plan. See here

The camper when fully loaded with fresh water and WD is engaged has these weights. The camper is loaded close to capacity but not over.

• 1,600# tongue weight

• 4,340# front axle (the weight distribution hitch force lands mainly on the front axle and the fresh tank is over the front axle)

• 4,040# rear axle

----------

9,980# GVW. My GVWR is 10,000# So I'm at the limit when I haul my 42 gallons of fresh water and we do often.

The frame rails are 10” x 9lb per foot thin I beam style or known as an MH beam. (Manufactured Housing)

The frame steel aligns with ASTM A529-50 High Strength Low Carbon Steel and responds in a bending test to be that steel.

Thanks

John

2005 Ford F350 Super Duty, 4x4; 6.8L V10 with 4.10 RA, 21,000 GCWR, 11,000 GVWR, upgraded 2 1/2" Towbeast Receiver. Hitched with a 1,700# Reese HP WD, HP Dual Cam to a 2004 Sunline Solaris T310R travel trailer.

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-04-2017 07:19 AM

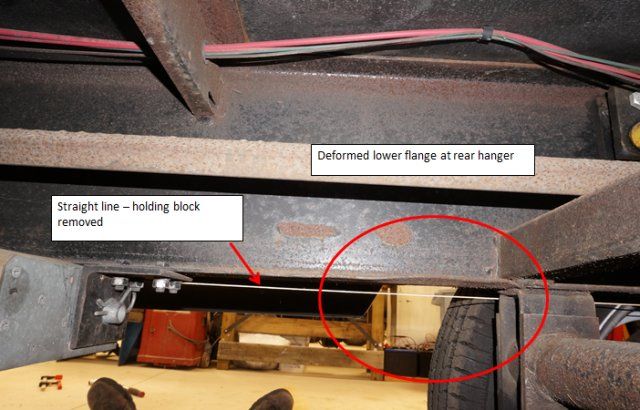

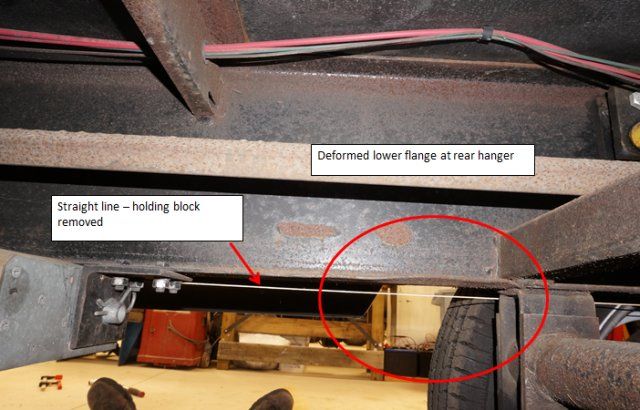

Now to the current condition, during 12/2016. These pics show the lower flange damage (deformation). The rust staining shows this is not new damage. This larger deformation occurred a while ago. To help explain this a little better, when an RV I shape profile frame bends from downward pressure (force), the lower flange distorts (buckles) and the web ( the center part) can also buckle if the force is large enough. The top flange stretches normally as it is an overhung load, normally. The heavier the damage like in a wrecked camper, the more the deflection in the web and lower flange. The pics of wrecked camper on the RV.net post I linked in my first reply is a lot worse. This damage I have is, what I will call, a mild case of deformation. I cannot see any deformation or thinning on the top flange or the web, there is no buckle in the web, only on the bottom flange.

Here is the slide to the slide opening in the current condition. The rear side. See the camper flange to the slide flange gap.

The bottom rear gap. 1 1/8”

The rear top. 5/8”

The front, the opposite out of parallel direction as the rear, just not as pronounced.

Here you can see the back corner is down compared to the front of the slide. The red line is following a piece of siding from the front of the camper up to the bend area at the front of the slide. From there the siding is tilting downward towards the back of the camper.

Notice the red line above the gutter rail

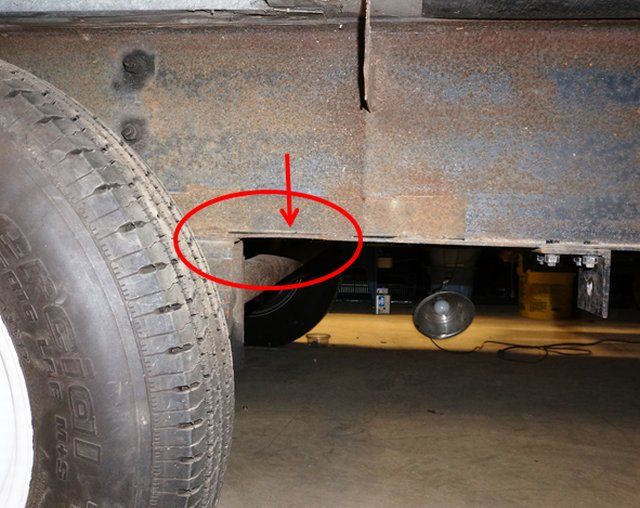

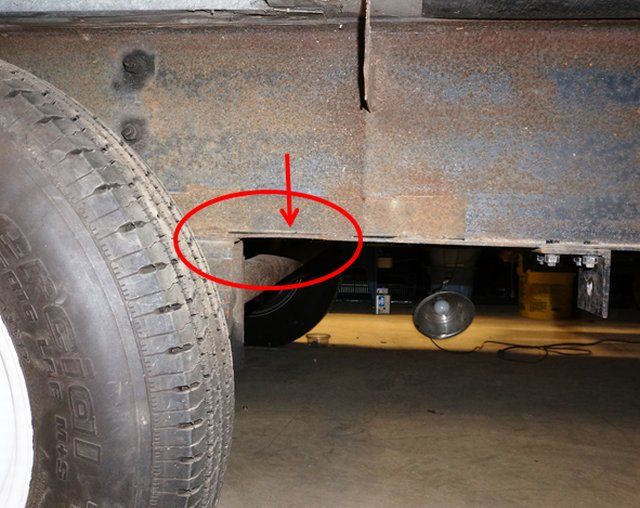

Here is the frame. It does not look that bent, but the rear overhang is 8 ½ feet from the rear hanger, so the bend does not have to be much. There is a string 13 ft 4 in. long pulled tight from the before the front axle all the way to the end of the frame. It sags where the frame is bent which right behind the rear spring hanger.

Starts at front hanger

All the way to the back wall

At the bend area

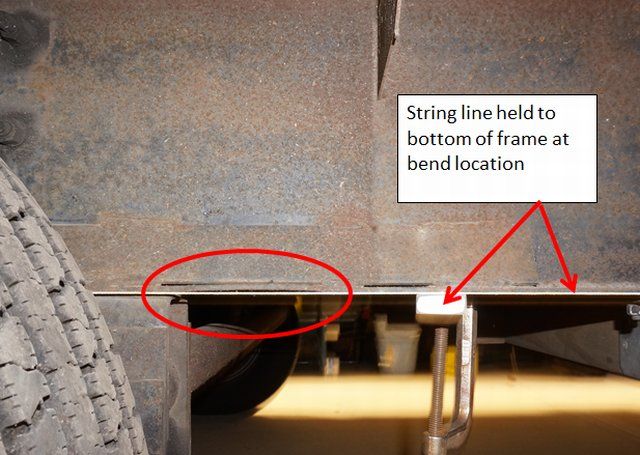

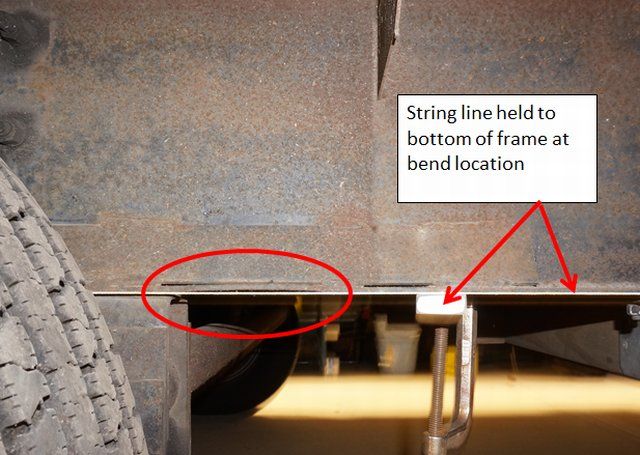

If I hold the line to the bottom of the frame at the bend point (flat metal plate and C clamp), the frame across the axles is straight and from the bend to the back of the camper, the frame is straight. So I only have one area of damage.

More in the next reply

Here is the slide to the slide opening in the current condition. The rear side. See the camper flange to the slide flange gap.

The bottom rear gap. 1 1/8”

The rear top. 5/8”

The front, the opposite out of parallel direction as the rear, just not as pronounced.

Here you can see the back corner is down compared to the front of the slide. The red line is following a piece of siding from the front of the camper up to the bend area at the front of the slide. From there the siding is tilting downward towards the back of the camper.

Notice the red line above the gutter rail

Here is the frame. It does not look that bent, but the rear overhang is 8 ½ feet from the rear hanger, so the bend does not have to be much. There is a string 13 ft 4 in. long pulled tight from the before the front axle all the way to the end of the frame. It sags where the frame is bent which right behind the rear spring hanger.

Starts at front hanger

All the way to the back wall

At the bend area

If I hold the line to the bottom of the frame at the bend point (flat metal plate and C clamp), the frame across the axles is straight and from the bend to the back of the camper, the frame is straight. So I only have one area of damage.

More in the next reply

2005 Ford F350 Super Duty, 4x4; 6.8L V10 with 4.10 RA, 21,000 GCWR, 11,000 GVWR, upgraded 2 1/2" Towbeast Receiver. Hitched with a 1,700# Reese HP WD, HP Dual Cam to a 2004 Sunline Solaris T310R travel trailer.

Related Content