- Good Sam Community

- Groups

- Truck Camper Group

- Forum

- Re: Happijac lubrication

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Happijac lubrication

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-17-2009 07:37 PM

First you have to make a little tool like this. An old hanger works good. This will serve two purposes, explanations following.

Remove the two screws that hold on the motor.

Pull the motor off the jack.

Pull out the spring loaded socket.

Remove the lever and pin...a pair of flush wire cutters works well. Wedge them underneath and they pop right out.

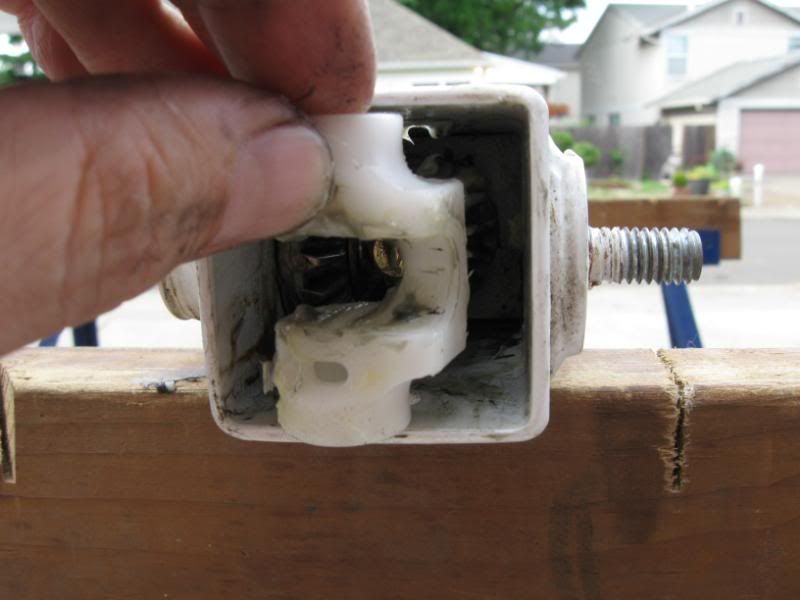

Remove the internal plastic manual mechanism...note how this is installed. one side has a round hole and the other an oval shape where the lever goes.

There is a "C" clip here, you need to remove it with the little tool you made. Just put it in from the side and pull back. It will pop right out.

Once you get the clip off then pull out the manual socket.

This is the hole in the socket that is to be oiled, but as you can see in the next few pics, the only thing that is being lubed is the socket itself.

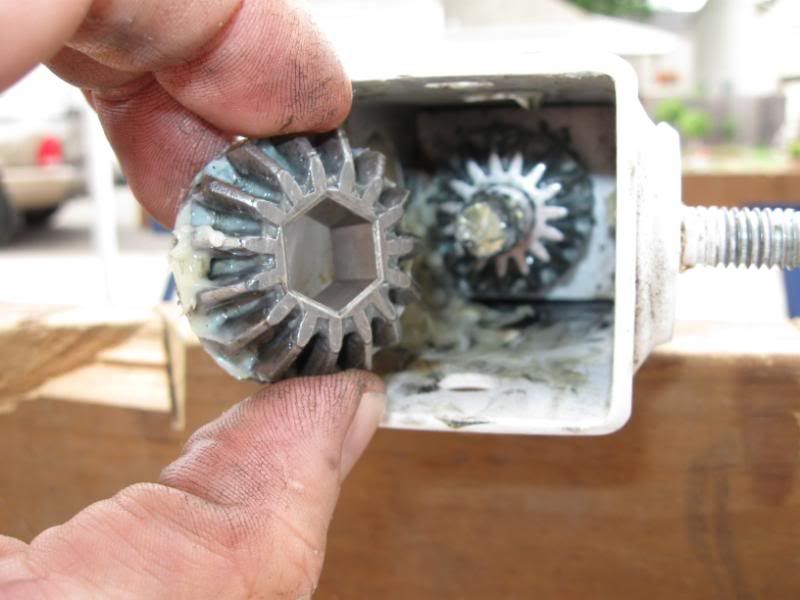

Once you pull out the socket, remove the manual gear.

Now as you can see the oil really goes nowhere. There is actually a lot of grease here. What your going to do next is pull this gear off that shaft straight towards you. Use that tool again to hook the gear from behind and pull it. You may have to do it a few times, the shaft gets a little burr on it but if it gets stuck ,just push it down and keep yanking, it will come off!

Once the gear comes off, this is what the back looks like. It has two slots. The slot that has the closed ends is what holds the pin in place. IT IS IMPORTANT YOU PUT THIS BACK TOGETHER THE WAY IT COMES APART!

Rotate the shaft so the pin is facing towards the corner and pull it out.

Now pull the leg assembly out of the jack housing.

Get ready to inspect and re lube.

Pull this cinch spring off and inspect this bearing.

Use an air ratchet or drill to turn the worm screw all the way out, inspect and re lube.

Re-assembly is just the opposite of the tear down. I found that even though this jack was sticking on me, it was still pretty well lubed, but maybe not enough.....Hope this dispels any unknown facts as to how these things work. One other note is that if the worm drive of the leg was to wear out...seems like you should be able to replace it rather than the whole jack. MMMMMM...haven't got to that yet but I wonder if they sell it seperatly? Does any one know?

- Labels:

-

Truck Campers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-01-2017 04:15 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-22-2017 07:46 AM

Thought I had a jack with stripped teeth or threads or something. Turned out was a bunch of rust accumulated jamming it up. Thorough disassembly greasing and oiling made it work like new again.

Probably should do the other 3......

2017 Heartland Torque T29 - Sold.

Couple of Arctic Fox TCs - Sold

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-24-2016 07:27 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-08-2015 06:18 PM

trail-explorer wrote:

Reminds me of the jackscrew on the MD80.

Oh yea, some of us can relate! Same technology for wing flaps too!

US Navy P3's.

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-08-2015 03:25 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-08-2015 01:42 PM

I recently had to service one of my rear jacks, but not the screw, the actual 12v motor. So the camper had been on the truck for about six months, and we were out camping and I went to lower the two rear jacks for stability. One worked and the other didn't. The first thing I did was check the fuses and of course the rear passenger side was blown, so I replaced it, tried the jack again and blew another fuse. To make for a shorter story, after getting home from that trip I pulled the jack off the camper and removed the motor to find out that the coil wires were bound up by rust on/in the magnet or stator. Also, the white plastic cup around the motor had water in the bottom of it.

I took it all apart, cleaned and dried everything, put it back together and silicone all the seals and it works fine now. I'll probably inspect and seal the other three now too.

on Vision Hauler 19.5's

'06 Arctic Fox 1150

'09 Nissan Murano S

'14 Ford F-150 FX4

'03 Polaris 700RMK VE, MBRP can

'04 Polaris 600RMK VE

'04 & '05 Suzuki Eiger 400's

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-03-2015 01:04 PM

magic43 wrote:

Wow, it is good to see this thread again. I believe that it once was a "sticky".

Still is a sticky...

Truck camper university, scroll down to jacks

http://www.rv.net/forum/index.cfm/fuseaction/thread/tid/25966285.cfm

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-03-2015 12:54 PM

1993 Dodge D350 Cummins

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jul-06-2014 06:47 PM

Since I disassembled, removed the skimmed paint, and properly lubricated my jacks (in August, 2012) I have had absolutely no problems. This thread was a lifesaver.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jul-05-2014 08:18 PM

I mighty be able to help with one of the simplier problems... rust!

Ijanet and I have spent a lot of time on The Gulf of Mexico Beaches over the last few year.

My jacks (Atwood) have a fine red rust hear and there all over them...

I was in my local Home Depot to get some stain for a home project... Ed, the paint department expert asked if there'd be anything elso.

I told him about the rust... asked if he had any ideas.

He suggested CLR, CLR

a product called Calcium, Lime, Rust

It was less than $6.00... I thought what the heck... I'll try it.

When I got home I used a scotch brite pad and the CLR on my jacks... hoping to get enough of the rust off to paint them...

Within a few minutes they were as clean and brilliant white as they were when I bought the camper new.

I will still paint the jacks with a thick, RustOleum paint... using a very small roller (that costs about $3.00 and comes with a roller pan.

Thanks again

Sleepy

AirFoil, Trimetric, LED lights, Platcat vent heat

2003GMC K3500 LT/Crewcab/duramax diesel/allison/dually/4x4/OnStar/front reciever mounted spare

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jul-05-2014 06:42 PM

I have happijac 4500's, 14 years old. I purchased this camper this spring and the jacks are in dire need of service. I have 2 completed and they work great. My problem with the remaining 2 is that I am unable to pull out the manual socket. I have removed the C clip and the sprocket is loose on the inside but the socket will not come out. I have tried everything I can think of short of welding in a coupler nut and using a slide hammer. The drawback to this is the socket will be ruined.

Any thoughts would sure be appreciated.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-22-2014 07:39 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-20-2014 08:19 AM

bigblue1978 wrote:

Great post. If the swivel at the bottom of the acme thread is badly rusted, the black tube will torque twist. This will cause the paint scraping because of corner to corner rubbing. This will also cause lots of groaning and grinding and popping noises. I lubricated my 4150 with 90 weight hypoid oil. with the black tube secured in the vertical position, I extended the screw as far as possible and then poured the oil(a few drops) onto the nylon nut and let it drain down. This takes several hours. I repeated this several times. Working the acme thread rod up and down, it eventually was loose enough to turn with only my thumb and forefinger. After everything is loose, grease the whole rod.

The nylon nut can fail and become stripped. The steel safety nut should prevent catastrophic failure. Similar nylon nuts are used in adjustable hospital beds and they do fail. The nylon nut can be replaced, but you will need advanced machining skills. For all that is at stake, replace the whole jack instead. A new jack is cheap insurance.(Oil the new jack with the hypoid oil.)

Welcome to rv.net Bigblue1978, I'm impressed that you know all about these pesky jacks having only joined RV.net TODAY....

Been through exactly what you described except that I had the jack on the bench and apart. I used WD-40 to loosen the acme nut, running it up and down on the threaded shaft with a drill attached to the TOP end... Took a while but finally the nut moved freely. Greased it with boat axle grease.

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-20-2014 05:54 AM

The nylon nut can fail and become stripped. The steel safety nut should prevent catastrophic failure. Similar nylon nuts are used in adjustable hospital beds and they do fail. The nylon nut can be replaced, but you will need advanced machining skills. For all that is at stake, replace the whole jack instead. A new jack is cheap insurance.(Oil the new jack with the hypoid oil.)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-29-2013 07:34 PM