- Good Sam Community

- Everything RV

- RV Tips & Tricks

- New Andersen WD hitch

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

New Andersen WD hitch

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-13-2012 05:35 PM

Anyone using one?

Andersen WD hitches

A U-tube video with the factory guy explaining it. You have to get past MR Truck doing his intro. Interesting 5th wheel hitch too.

http://www.youtube.com/watch?v=xvM7mCnqmwo&feature=related

It looks like this

I'll hold my comments for a short while to not cloud your thoughts. Ideally we can find someone here using one to quiz them on it.

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-24-2012 06:46 PM

BenK wrote:

John !?!... you've got me !!!!

Cleaning out the garage and coming in to check this site, so apologize for the

quickie comments...

Well, lots of assumptions on my part.

Assumed the ball is held in there by a traditional nut, but will have to see

how they capture it

Thought a traditional coupler with a pawl, but in looking at the image...there

is no latch.

So how in the world did they get the ball past the interference fit?...but that

is another assumption...that the coupler has an interference fit for the ball

like these images:

so if traditional, then that pawl will take the forces...but...since not traditional

how do they keep the ball from coming off?

By interference, meaning that the coupler has a lower hemisphere smaller

in dia than the ball dia. The pawl moves out of the way to allow the

ball to move backwards and then drop out.

That is also how I saw it.

I've not seen all of the types of couplers, but *ALL* of the one's

have seen look like the cross section diagram above

Architecturally these latches reduce the dia of the opening below the

ball equator so that it will not come out. Not to have that kind of

force on it statically and worse dynamically

Any asked them about this and if so, what was their position ?

Since the original image did not have a latch, did they remove the

latch and is now riding on what?

1996 GMC SLT Suburban 3/4 ton K3500/7.4L/4:1/+150Kmiles orig owner...

1980 Chevy Silverado C10/long bed/"BUILT" 5.7L/3:73/1 ton helper springs/+329Kmiles, bought it from dad...

1998 Mazda B2500 (1/2 ton) pickup, 2nd owner...

Praise Dyno Brake equiped and all have "nose bleed" braking!

Previous trucks/offroaders: 40's Jeep restored in mid 60's / 69 DuneBuggy (approx +1K lb: VW pan/200hpCorvair: eng, cam, dual carb'w velocity stacks'n 18" runners, 4spd transaxle) made myself from ground up / 1970 Toyota FJ40 / 1973 K5 Blazer (2dr Tahoe, 1 ton axles front/rear, +255K miles when sold it)...

Sold the boat (looking for another): Trophy with twin 150's...

51 cylinders in household, what's yours?...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-24-2012 06:18 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-24-2012 06:01 PM

I went out and looked at my ball coupler. This is the one I have. http://www.shelbyindustries.com/custdocs/class%20iv%20a-frame%20coupler.pdf

I also took a number of dimensions to make a drawing of the coupler cross section. This was in an effort to help sort out if this top dome plays a role in removing some force off the latch by the Anderson WD system. After seeing what is in these pics I came to a conclusion without the drawing.

The top dome is 1/4" above the top of the latch area. You can see this in this side view.

Here are some other shots of the coupler.

Latch open

Latch closed

Front view

Side view with tow ball in place and latched. I also measured the clearance up and down and front to back when latched. Both where 1/8" total movement.

Now the views that where convincing to me of what would occur when hitched up and WD engaged.

A side shot with the tow ball next to the coupler. Notice the flat spot on top of the tow ball. Every tow ball I have in 2 5/16" has this flat spot. I do not know if every 2 5/16" ball has this, mine do. That flat spot will play a key role in the next pics.

Two side shots mocking up how much engagement at the top of the tow ball will have with the Anderson WD hitch pushing the coupler forward and pulling to tow ball to the back of the latch area.

And 1 more

From those last 2 pics I have come to this conclusion:

- The flat top tow ball eliminates approx 3/16" of the top of the ball sphere from touching inside the ball coupler.

- 1/8" of vertical clearance exists up and down with the coupler latch.

- If the ball drops 1/8" down from clearance plus the 3/16" flat top ball, there would be no dome engagement if the ball is pushed down and back into the latch.

- The back of the ball sphere and the back inside of the coupler dome are curved and create a very good sliding cam angle of the 2 parts in relation to each other.

From the above bullet points I conclude:

A 1,400# tongue weight creates a 1,400# downward force to seat the coupler on the ball.

For a tongue weight of 1,400# the Anderson WD hitch could produce between 6,000 to 7,800# of force pulling on the bottom of the chains. Even if it was 4,000# as Anderson stated in their video it would not change the conclusion.

The higher WD chain force will overcome the tongue weight pushing down. The TT will cam up on the back side of the tow ball and create the 1/8" clearance up top. The TT tongue will lift up the 1/8"and combined with the 3/16" flat to ball, there is no dome engagement left. Almost all 6,000 to 7,800# of WD force pulling on the tow ball will be transferred into the safety latch.

This is my conclusion from what I saw tonight. Anyone see something I missed in this theory to change the outcome?

Thanks

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-24-2012 09:09 AM

dougsee3 wrote:

I can not post a pic. from my phone.

If you look at the TT hitch were the ball fits into the top of the ball socket.

The trailer TT hitch would have to rise up away from the ball to put excessive force (or all of the force) against the coupler latch.

What the latch is really doing normally is preventing the hitch from lifting off the ball rather than taking all pressure from braking and in this case the chains forcing the latch against the ball.

Dougsee3,

Good point. I do not know what your coupler looks like. I just happen to have these pics on my photo server from long ago. This TT coupler was in an accident where the TT flipped on it's side so if someone finds damage in these pics that is why.

This Shelby coupler is the same type as mine. I will try to get pics of mine tonight if the weather cooperates.

On this brand/model coupler "it appears,” the entire rear portion of the latch withdraws from the ball. The top of the coupler "appears" to have a small formed dome in the top of the coupler.

The question now is does that formed dome create enough of a ledge to keep all the force of the WD from the Anderson unit to not apply it to the latch?

OR

Does the strong WD force pulling back does still apply force on the latch even with the domed top?

This could be a race of forces as to who wins. If the WD chain force is high enough it “may” overcome the tongue weight pushing down.

Then do the chains still pull the ball out of the dome partially and down into the latch and you still end up with latch issues? H'mm good question. I need to think on this one some more. Not enough time duirng lunch.

Does yours look like this?

All ball couplers may are not made the same.

Thanks

John

PS If you need help posting pics, PM me an email address, I can help.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-24-2012 06:58 AM

I guess my question was too simple. I was wondering if a-frame members were more resistant to let's say a 4x load applied the way Anderson does versus the vertical load of 1x by spring bars. Some particular spec (compression, modulus, inertia, ect, over my head!) of a tube to 'better' resist a force, ie the bending spec is X versus Y pulling on bottom which is Z times greater. I see there is a lot more going on, great explanation.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-24-2012 06:23 AM

If you look at the TT hitch were the ball fits into the top of the ball socket.

The trailer TT hitch would have to rise up away from the ball to put excessive force (or all of the force) against the coupler latch.

What the latch is really doing normally is preventing the hitch from lifting off the ball rather than taking all pressure from braking and in this case the chains forcing the latch against the ball.

8.1 Workhorse

Acme Eze-Tow Dolly

_________________________

Last RV

2005 2500 Avalanche 8.1/3.73

2004 30' Terry Quantum 290FLS

Calgary Alberta

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-23-2012 06:30 PM

be part of the WD Hitch kit.

That would add cost, but a better solution to all. From busted self tappers to

deformation to sliding along.

Issue would be that the A frame angles may or most likely not be 'standard'. So

even more expense for the HD Hitch OEM to provide cross member kits

Then to solve that issue, a variable gusset at both ends of that cross

member...more cost but net less cost for this

But that is the best solution to all of this, IMO

1996 GMC SLT Suburban 3/4 ton K3500/7.4L/4:1/+150Kmiles orig owner...

1980 Chevy Silverado C10/long bed/"BUILT" 5.7L/3:73/1 ton helper springs/+329Kmiles, bought it from dad...

1998 Mazda B2500 (1/2 ton) pickup, 2nd owner...

Praise Dyno Brake equiped and all have "nose bleed" braking!

Previous trucks/offroaders: 40's Jeep restored in mid 60's / 69 DuneBuggy (approx +1K lb: VW pan/200hpCorvair: eng, cam, dual carb'w velocity stacks'n 18" runners, 4spd transaxle) made myself from ground up / 1970 Toyota FJ40 / 1973 K5 Blazer (2dr Tahoe, 1 ton axles front/rear, +255K miles when sold it)...

Sold the boat (looking for another): Trophy with twin 150's...

51 cylinders in household, what's yours?...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-23-2012 05:51 PM

red31 wrote:

Would this system be less stressful on the trailer's a-frame members?

Hi Red,

A quick answer to your question is, it depends.

The hitch is advertized as one size fits all and does not list a bottom end but does a top end of 1,400# TW and 14,000# tow rating. If every trailer and TT A frame was built like the 1,400# TW, 14,000 GVW rated frame is, then this would be easier to answer.

Let's look at a few things and the differences of a traditional WD hitch and the new Anderson as they pertain to TT's.

For explanation purposes the conventional WD hitch has chains or L brackets to hold the ends of the WD bars. I'll use the chain example however both have the same effect on the WD bar for what I am going to state.

- On a conventional WD hitch when TV and TT are towing down a level road straight ahead each chain is under equal loading. And so is the Anderson.

- During a turn with a conventional WD hitch on level flat road the chain load is again close to equal in the big picture of things. There are some smaller changes but not drastic. On the Anderson in a turn the chains change force from the left to right side some. The inside chain become a little looser and the outside turn chain becomes a little tighter. As the turn continues the hitch shank slips in the shank socket both chains came back to be closer to equal. The chain forces change but not what I would consider major. As long as you always went camping on perfectly level ground there would be a lot less A frame issues on a conventional WD hitch.

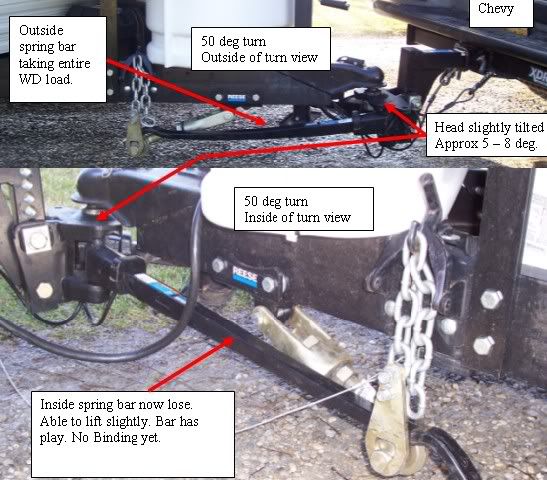

- Now lets enter the real world of camping. The TV going in and out of turns all the time where an angle exists between the TV ground and the TT ground. Here large changes will come in the conventional WD hitch. If the TV is tilted enough the WD head tilts with the truck and the inside turn WD bar and completely unload. The outside WD bar now is taking all the load so that out side bar can approach being twice as loaded in the chains. This action creates an unbalanced load in the A frame. That unbalanced load in some cases has broken the A Frame on TT frames that have had issues if the tongue weight and WD bars where large enough. The Anderson chains do not change as drastic in loading even on uneven ground. So in this perspective the Anderson is better IMO.

Here are some pics to show what I was referring too. Here is the turn.

The inside WD bar I could rattle around with my foot. In my case I had a 5" C Channel A frame. 5" C Channel is strong enough to resist the twisting that can come from a WD hitch for the 1,200# TW that camper had.

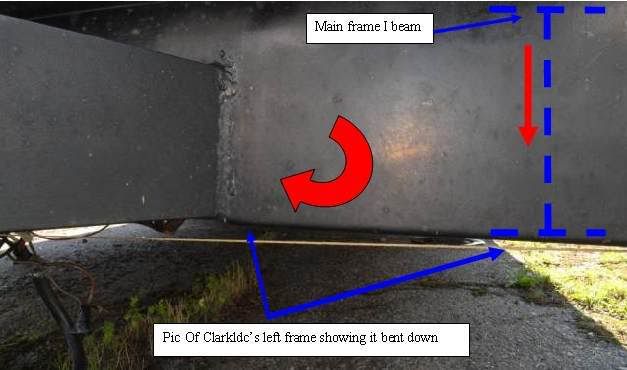

Now what WD forces can do if the A frame is not strong enough for these unbalanced loads?

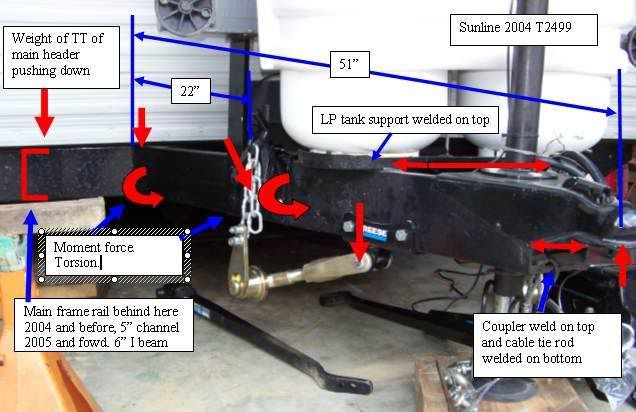

One mode of failure is the A frame side rails twist. The header and battery shelf needs to resit that twist. If they cannot then the header can buckle and the battery shelf. Here is the start of the problem

Left gone unchecked the header buckles more and more and eventually separates from the A frame members.

Below you can see here how the chains pull on the top of the A frame creating the force that makes the twist. The key to not having this become a problem is to have the A frame rails stiff enough or reinforced to resist the twist or the header made to handle the twist. In my case my camper in this pic was made strong enough to resist the twist.

The Anderson does not have the same loading on the top of the A frame or large unbalanced chain loads so that mode of failure would not be the same as a conventional WD hitch on a light A frame.

The Anderson does have other concerns the conventional WD hitch does not.

- The chain loads on the Anderson are a lot higher then the conventional WD hitch. We are still sorting out if it is 2, 3 or 4 times higher. While they pull forward they are at an angle to the A frame pulling inward. So you are pulling on the bottom of the A frame at an angle and with a higher chain load. If you have a light A frame the higher WD chain force and the angle of pulling is a new thing to work through if it is a problem or not.

- The next area of concern is the urethane spring bracket. They provide a clamp feature that uses 5/8" bolts to squeeze the side of the A frame for grip. And they want those bolts torqued to 150 ft. lb. On a big A frame that is beefy, that is not a problem. In thin wall box tubing of light weight TT's it may deform the tube and then you are towing the camper by pulling on that deformed tube. See here for the clamp.

Since all A Frames are not created equal, making a generic marketing statement that one size fits all is a stretch. If you have a thin wall tube A frame, check with your TT manufacture if the A frame can handle this hitch.

Hope this helps

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-23-2012 02:31 PM

Gallifrey wrote:Most likely, it wouldn't damage the coupler body itself, but may very well destroy the latch. A latch kit for a common, rebuildable coupler isn't much money and is easy to replace. Not all couplers are rebuildable. To replace the whole coupler, I charge $150-200 for labor, plus the coupler, $30-60, to come out to wherever the trailer is and do the job. Mobile welding rates vary by geographic area. Shop welding rates also vary in comparison to mobile rates.

Anyway, if someone were to try this hitch out and it did damage the safety coupler, any ideas on how much it would cost to repair or replace the coupler?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-23-2012 11:41 AM

and forth inside the coupler...then does the chain plate at the bottom of the ball

shank then get bangs around?

Does it then deform the hole and/or the shank?

Since your analysis says the likelyhood of the ball banging around the coupler

is slight in relation to the acceleration numbers...this is a moot point

Have a P3 and my brake pedal light switch makes about 1/64"-1/32" before the

MC rod is moved. Set my P3 to skid the trailer tires at approx 25 MPH on dry

pavement.

Your comments settles or at least alleviates my concerns on the possible movement

of the ball within the coupler, but am still not comfortable with the WD forces

on the coupler latch/pawl.

1996 GMC SLT Suburban 3/4 ton K3500/7.4L/4:1/+150Kmiles orig owner...

1980 Chevy Silverado C10/long bed/"BUILT" 5.7L/3:73/1 ton helper springs/+329Kmiles, bought it from dad...

1998 Mazda B2500 (1/2 ton) pickup, 2nd owner...

Praise Dyno Brake equiped and all have "nose bleed" braking!

Previous trucks/offroaders: 40's Jeep restored in mid 60's / 69 DuneBuggy (approx +1K lb: VW pan/200hpCorvair: eng, cam, dual carb'w velocity stacks'n 18" runners, 4spd transaxle) made myself from ground up / 1970 Toyota FJ40 / 1973 K5 Blazer (2dr Tahoe, 1 ton axles front/rear, +255K miles when sold it)...

Sold the boat (looking for another): Trophy with twin 150's...

51 cylinders in household, what's yours?...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-23-2012 11:08 AM

BenK wrote:I believe the new SAE J2807 Recommeded Practice for towing performance requires a SRW TV, operating at its GCWR, should be able to accelerate from 0 to 30 mph in 12 seconds. The corresponding acceleration, assuming it is constant, would be 3.7 ft/sec/sec or approximately 0.11 G. The force required to accelerate an 8000# TT at 0.1 G would be 880#.

Think there is another metric and that is during acceleration.

Would that then pull the ball away from the coupler back side to transfer the loading to the coupler front side?

How much is the force during acceleration and will that over come the tension of the plastic springs ?

Even if a TV could achieve twice this rate of acceleration, is seems unlikely that the combined acceleration force, aerodynamic drag, and rolling resistance would ever be great enough to exceed the forward thrust of the coupler against the ball.

Would there also be enough force to repeat this during the drive? Guess dependent on the frontal area of the trailer and other drag vs the TV pulling to a higher speedI believe SAE 2807 also specifies a TV should be able to accelerate its GCWR from 40-60 mph in 18 sec. The corresponding acceleration would be about 0.03 G. Again, not at all likely that the coupler would be pulling rearward against the ball.

With my setup and the controller leading the trailer braking, that would also have the trailer pull the coupler off the back side.Not sure what controller you have. Let's assume the leading "boost" is set to 20% of maximum TT braking force. That probably means the boost-related braking force would be about 10% of the TT's weight.

If we assume the TV weighs 7000# and the TT weighs 8000#, the boost braking would decelerate the combination at about 800/15000 = 0.05 G. In addition to decelerating itself, the TT would be pulling rearward against the TV with a force of about 350#. Again -- not nearly enough to overcome the forward thrust of coupler against ball.

Also assume the contact area of the plate steel hole and the ball tail end would not work itself. That the contact area is sufficient to distribute that constant load change from working the metal contact area.I don't know what you mean by this, so I cannot comment.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-23-2012 08:57 AM

Would that then pull the ball away from the coupler back side to transfer the

loading to the coupler front side?

How much is the force during acceleration and will that over come the tension

of the plastic springs ?

Would there also be enough force to repeat this during the drive? Guess dependent

on the frontal area of the trailer and other drag vs the TV pulling to a higher speed

With my setup and the controller leading the trailer braking, that would also

have the trailer pull the coupler off the back side.

Also assume the contact area of the plate steel hole and the ball tail end would

not work itself. That the contact area is sufficient to distribute that constant

load change from working the metal contact area.

1996 GMC SLT Suburban 3/4 ton K3500/7.4L/4:1/+150Kmiles orig owner...

1980 Chevy Silverado C10/long bed/"BUILT" 5.7L/3:73/1 ton helper springs/+329Kmiles, bought it from dad...

1998 Mazda B2500 (1/2 ton) pickup, 2nd owner...

Praise Dyno Brake equiped and all have "nose bleed" braking!

Previous trucks/offroaders: 40's Jeep restored in mid 60's / 69 DuneBuggy (approx +1K lb: VW pan/200hpCorvair: eng, cam, dual carb'w velocity stacks'n 18" runners, 4spd transaxle) made myself from ground up / 1970 Toyota FJ40 / 1973 K5 Blazer (2dr Tahoe, 1 ton axles front/rear, +255K miles when sold it)...

Sold the boat (looking for another): Trophy with twin 150's...

51 cylinders in household, what's yours?...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-23-2012 05:14 AM

Anyway, if someone were to try this hitch out and it did damage the safety coupler, any ideas on how much it would cost to repair or replace the coupler?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-22-2012 06:34 PM

Thanks, your thoughts confirmed mine. Just I did not have the drag estimates at speed. I did the force to get the 9,200# TT rolling and it was so low that I thought I made a mistake.

The TT drag does not seem to be enough to allow the tow ball to come off of the safety latch. So as I suspected they are towing with the chains potentially all the time.

I'll have to investigate the ball coupler saftey latch further. I have never even seen a rating on the latch when used in this manor. The rating is normally always by the ball pulling the camper by the coupler nose and the amount of tongue weight.

I still do not like the fact that one could be potentially towing the camper with the urethane spring frame brackets where the chain attaches. And as the WD chain force goes up as we suspect it will, this issue of the pulling on the brackets gets worse.

Maybe Anderson will publish some more WD data to help alleviate these concerns.

Thanks

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-22-2012 12:06 PM

I can respond to some of your points -- but not necessarily in the order in which you made them.

JBarca wrote:Let's assume each of the two chains is pre-tensioned to 2000# and each chain is parallel to the longitudinal axis of the TT. The chains would be pulling rearward against the spreader plate with a combined force of 4000#. With the TT at rest, the tension in the chains would cause the ball coupler to push forward against the ball with a force of 4000#.

Chains towing the camper When the TV is stopped or rolling forward at low speed, the chains are pulling the camper. The chain force is high enough that is it pulling the camper forward and seating the tow ball into the latch side of the ball coupler. Clearance exists between the ball sphere and the front part of the coupler that normally pulls the camper. The rolling resistance of the camper on the 28.3" OD tires on concrete or black top is less then the chain force under these conditions.

When being towed on level ground at 70 mph, the combined aerodynamic drag and rolling resistance acting on a TT probably would be less than 1000#, but let's assume it is 1000# for arithmetic simplicity. This means, as your title suggests, the chains would be towing the TT.

The combined chain tension of 4000# now is divided into 1000# pulling forward on the TT and 3000# pushing forward on the ball. IMO, it is highly unlikely that there would be any "banging" of ball against coupler. It looks to me as though the ball always will be pre-loaded in the forward direction.

Tow ball towing the camper There may be a point where the wind drag on the front of the camper or up hill (gravity) loads increase enough that the TT drag is higher then the WD tension in the chains. In this case the TT would shift backwards by the clearance in the coupler when the wind drag force overcomes the WD chain force. The tow ball leaves the coupler latch and now becomes seated into the front part of the ball coupler. The TT is now pulled by the ball coupler.Now, let's assume you actually could tow a 10,000# TT up a 6% grade at 70 mph. This would result in an additional towing force requirement of 600#. The previously calculated forward force on the ball would be reduced from 3000# to 2400# -- still sufficient, IMO, to preclude any "banging" of ball against coupler.

What we do not know yet, is on a 1,400# TT tongue weight, 9,200# GVW TT does the wind drag or up hill drag ever get high enough to let the ball coupler tow the camper? And any guesstimate on what speed that may be? I picked those weights only because they line up with my camper. The issue can occur under other TV and TT combos as well.IMO, if each chain is pre-tensioned to 2000#, it is highly unlikely that the combination of wind drag, uphill drag, and rolling resistance will ever result in the ball pulling forward against the coupler.

The high load on the coupler saftey latch is a large concern. If the TT seats and reseats back and forth constantly as you tow down the road, the fatigue on the coupler saftey latch is something to think through.IMO, the TT will not seat and reseat back and forth. However, I do think that coupler manufacturers should be asked to comment on any possible consequences of operating with the coupler constantly pushing forward against the ball.

IMO, your previous post gave a excellent analysis of how much WD torque might be generated by the Andersen hitch. The new hitch is rated for 1400# tongue weight. I doubt that a combined chain tension of 4000# would provide sufficient WD torque for a 1400# TW. It would be good if Andersen could provide some before and after axle load data.We understand how it has the ability to distribute weight. How effective it is and sensitive it is is another question.

Ron

- Need 5th wheel hitch and information in Tow Vehicles

- Fifth Wheel Hitches and sideways tilt in RV Tips & Tricks

- Should I install a WDH? in RV Tips & Tricks

- Is MB GLE450 sufficient for pulling Bullett Crossfire 2220ML in Tow Vehicles

- ECOTRIC and other off-brand turnover ball style hitches in Tow Vehicles