- Good Sam Community

- Everything RV

- Tow Vehicles

- Re: Dexter HD Suspension & EZ-Flex Install (long w...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Dexter HD Suspension & EZ-Flex Install (long w/ pictures)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jul-02-2008 06:00 PM

Now it's worth mentioning here that this type of job isn't exactly for the "faint of heart"... Basically what your going to do is to put your TT on Jack stands and rip off the suspension and install a new one... Your going to need a pretty good assortment of standard mechanics hand tools and an air compressor with a variety of air tools is also very helpful... I would also suggest that you buy the

Harbor Freight Ball Joint Tool

that you see in this post... It is used for pressing in bronze bearings and serrated bolts and works very well for this application...You could just use a big hammer and beat things into submission, but pressing the bearings and bolts in is a lot more elegant and easier on the frame and also the installers hands... I also used an air operated impact (gun) wrench, an air operated ratchet wrench, demolition bar, numerous 1/2" drive sockets, 3 pound hammer, grease gun, assorted screwdrivers, vise grips and other hand tools...

Start the project by putting your trailer on jack stands on a good firm surface... I also used my 6 stabilizer jacks attached to the trailer to further aid with stability... Here are some photos of that...

You should also have 2 or 3 hefty jacks, either the bottle type or floor type to aid in the installation... I use a 4 ton floor jack and a 12 ton bottle jack... The 12 ton picks up the TT effortlessly and is small and compact... Here are a few photos of them...

Start by removing the standard OEM idlers and shackles... This is done by removing the lock nuts on the inside of the suspension components and then hammering the bolts out of the hangers... All the bolts on my OEM suspension system were serrated, so using the impact gun to turn them and remove them would have damaged the shackle hangers by reaming out the mounting hole... If I would have done that then the new serrated bolts would have no material to bite in to... Here are a few pictures of the old suspension components...

Here is the rear OEM bolt...

In this photo the springs have been removed from the idler and their plastic bearings have not yet been removed...

Once the old components have been removed, you can begin to install the new ones... When pressing in the new bronze bushings, it is a good idea to use a pilot bolt or installation bolt so that the soft bronze bearing does not distort or bend... Here is a bolt I used for that purpose... Note that I ground off the serrations... This bolt is also used to push out (hammer out) the plastic bearings...

Here are a few typical plastic bearings after about 6000 miles... Some were already showing signs of extreme wear...

Now we can install the bronze bushings in the spring eyes... Apply grease to the inside of the spring eye, the outside of the bronze bearing, and the inside of the bronze bearing as well... Then use the Harbor Freight Ball Joint Tool (HFBJT) to push the bronze bearings into the spring eye as shown below...

Once the bearing is pressed into the spring eye, then we press the serrated greasable bolt into hanger using the HFBJT...

This isn't the spring eye but here we are pressing the idler bolt into the hanger the same way you would do it with the spring hanger...

Once you complete the spring eye ends, then you can install the EZ-Flex Idler... It is installed by holding the idler between the frame hanger, inserting the proper size bolt and using the HFBJT to press the serrated bolt into the hanger... In the picture below the EZ-Flex idler has been hung on the bolt...

In the picture below, the serrated bolt is being pressed into the hanger...

Once you have the EZ-Flex Idler mounted you can install the HD shackles for the front and rear springs... Here are a few photos of that operation... The photo below shows one shackle in place...

The photo below shows the second HD shackle being installed...

And this is what the assembly looks like when completely installed...

Here are a few photos from underneath the trailer looking at the inside view of the suspension components...

And here are a few extra views of the HFBJT in use... This tool was really a life saver... We used a similar tool that my buddy had at his shop when we did the previous trailer and I knew I would need a similar tool to successfully complete the installation of the HD EZ-Flex Kit...

And the finished product with the TT wheels again mounted...

It took me all day yesterday to install the EZ-Flex kit and HD suspension shackles on the curb side of the TT... I spent about 8+ hours on it but it was somewhat a learning experience... Today I installed the street side portion of the kit and I did that in about 4 hours... Not too bad for the first time although I don't plan to do another any time soon...

I haven't done a test ride yet - that will come in about 2 weeks when we attend another rally, but I suspect the HD Suspension shackles and EZ-Flex will be a big improvement just like the last one was, although my last one had a solid idler assembly, not rubber shock mounted like the EZ-Flex...

I'm having some problems getting grease to flow in the spring eye portions of the greasable bolts... I called Dexter Tech support and they suggested I reverse their direction... All the greasable bolt holes should run in a horizontal plane facing either the front of rear of the TT as opposed to pointing either skyward or ground ward... Dexter says the grease will not migrate properly if they are in the up or down position... So I reversed the direction of the leaf spring eye bolts and I still can't get grease into them...

I'm going to run the TT a bit and see if the bronze bearings loosen up to the point where they will take grease readily... I remember my last TT being like this and sometimes I had to jack the frame a bit to relieve pressure on the greasable bolts... We'll see what happens with this issue... There were no problems getting grease into the center idler and shackles...

Les

2000 Ford F-250SD, XLT, 4X4 Off Road, SuperCab

w/ 6.8L (415 C.I.) V-10/3:73LS/4R100

Banks Power Pack w/Trans Command & OttoMind

Sold Trailer - not RV'ing at this point in time

HUNTER THERMOSTAT INSTALL

HOME MADE WHEEL CHOCKS

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-03-2010 09:46 PM

To your comment on the cheap nylon bushings, that is not a Skyline exclusive. Mine also have the same cheap nylon bushings and talk to me each time I do a turn on the TT reminding me just how cheap they are...

Thanks for sharing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jul-28-2010 07:52 AM

Thank you for the response. I kept my original question short on info to keep from boring anyone. I had reviewed the work you did on your hangers and I have congratulated you many times in my mind over the past year. If I had the ability to weld mine would look very much the same as yours especially with the load distribution across the frame.

My signature shows what I pull and with what. The unit sits on top the springs and I had 2" box steel inserted between the springs and axles to level the 5er stern-aft when towing. Yesterday I made two cardboard templates the size of the K71-653-00 and K71-652-00 EZ Flex Equalizers (1 ea) per specs Dexter provides guessing at the bolt hole size for 7/16" or .4375" bolts. Also made 2 shackles, guessing at size being 3.5" x 1.25". Attached shackle templates to equilizer templates and hung the unit(s) on the existing 4" equilizer hanger mounting bolt. Result indicates a 1.4" reduction in overall 5er height; which does not present a tire-to-fender problem, but counters the 2" original lift for towing.

It appears I have 4 options. 1) Trade for a new 5er, 2) Learn to weld, 3) Find a capable person to weld the mod, 4) Install HD suspension parts from Dexter having improvement over plastic bushings. Option 3 being more difficult than it should be or else I'm just too picky about QA, but I'm not going to change at my age.

Thank you for your posts, pics showing excellent processes/work/mods, and support. You and Les always take the time to help others as we all make our way.

R. Kaiser

USACE Retread

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jul-27-2010 07:20 PM

kaiserrw wrote:

Just wondering if anyone has installed the EZ Flex Equilizer on a trailer with tandem AlKo axles on 35" spacing and a 4" equilizer. I spoke to a Dexter rep yesterday concerning which packaged parts would be appropriate and was told it is doubtful the system could be properly installed to work on my trailer.

Since my 5er does not have Dexter components under it, I can understand their reluctance to assure a potential customer their product will function as desired.

I have done the EZ flex on my Alko setup but not knowing exactly what you are referring to the 4" equalizer. You mean the monster vertical equalizer? Actually Dexter has one like that too. Is this the one you mean? This is a Dexter.

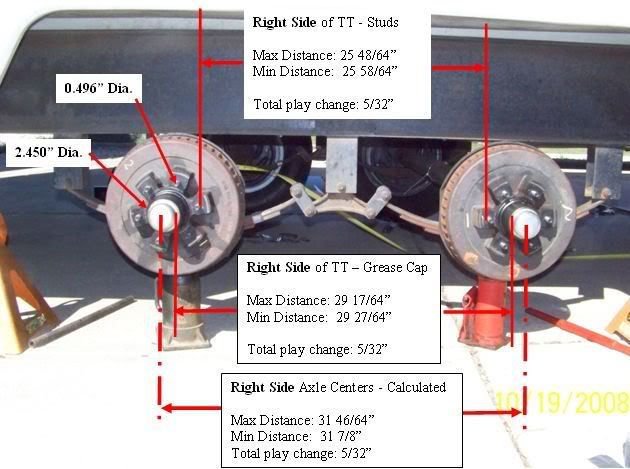

Mine are 32" nominal axle centers. This pic is before my alignment corrections.

And by using the EZ flex in place of the Alko equalizer which was wider left to right I lost some tire clearance, top of tire to bottom of fender. But I corrected for it on the hanger. This clearance issue was also altered by me going from 5,200# axles to 6,000# axles as the 6K's have a beefed up axle seat and drop the camper 1/4" The EZ flex dropped me 1/4" as well with the Alko equalizer so I had 1/2" to make back up.

The Alko laying over top of the Dexter

If you are referring to that 4” tall equalizer, you are going to have to do some hanger work similar to the work I did. But if you do, then the EZ flex should work. I doubt you can get it to work and not have a tire to fender issue on the pure stock configuration.

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jul-27-2010 08:08 AM

Since my 5er does not have Dexter components under it, I can understand their reluctance to assure a potential customer their product will function as desired.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jul-19-2010 03:40 AM

taking grease. Jacked the trailer up a little to relieve some of the pressure and finally got them to take the grease.

I suspect next time will be easier after they loosen up a bit. Used Valvoline fully synthetic grease.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-27-2010 10:23 PM

On another note, I was going to buy a ball joint tool to finish the job after I ran into the initial problem but they wanted $120.00 up here for the kit, a little rich for my blood. Once again, thanks to everyone who has contributed to this post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-27-2010 06:03 PM

hoghead55 wrote:

I need help with the wet bolt install. I have a huge clamp from my welding buddy but cannot get the bolts to press in flush with the hanger. I am not having a problem pressing the old bolts out. Is there another way to seat the bolts such as using an impact wrench and pulling the bolt in place? I have tried driving the bolt in the last little bit using a sledge hammer and socket but no luck. Any suggestions would be greatly appreciated to finish the job.

This clamp is about the smallest that will work. It has a 3/4 ACME thread. I have used this on 3 installs and I can attest anything smaller and it will not do the job. The HF ball joint tool I believe and is 1" fine thread. You can get more power with the ball joint tool and if I have to do another one I will buy one.

A few things that help reduce the power needed:

Try and align the serreated teeth on the new bolt with as many of the prior cut teeth in the hanger. It helps vereses cutting all new teeth in the hanger.

There is 1 limited trick with the C Clamp if you have a 3/4" or larger one to start with. Arranging the head of the bolt to be on the screw side, preload the clamp as much as you can. Use sockets to not mark the grease fitting/hanger. 1 or 2 impacts on the screw using medium force hammer can seat them. Do not whale heavy with a heavy hammer.

You mentioned using the nut to draw in the bolt. No do not do that. The nut is made of low gage metal and will strip out for sure. I riped up several old one taking them off once rusted on.

Good luck and hope this helps

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-27-2010 05:29 AM

You will like the results. Quiets and smooths the ride remarkably.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-26-2010 08:51 PM

hoghead55 wrote:

I need help with the wet bolt install. I have a huge clamp from my welding buddy but cannot get the bolts to press in flush with the hanger. I am not having a problem pressing the old bolts out. Is there another way to seat the bolts such as using an impact wrench and pulling the bolt in place? I have tried driving the bolt in the last little bit using a sledge hammer and socket but no luck. Any suggestions would be greatly appreciated to finish the job.

Read the first post. The tool from Harbor Freight is shown which does the job. Do not try to pull the bolt in with an impact. You will strip the bolt.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-26-2010 08:25 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-23-2010 08:54 AM

Thanks to all who contributed for a job well done.

Sidney

2002 Excel,Ltd,30RGW,Hughes Autoformer,Honda Eu1000i, ClearSpot 4G+,

http://www.kayepics.com

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-20-2010 04:45 PM

First, I was surprised to learn there are five different Equaflex versions, according to their published pricing information, apparently for different weight trailers and number of axles.

Mine is is the EQ-4K, which is for lightweight trailers ranging from 4K-8K lbs.

My mechanic friend made the job look easy. I showed him this excellent and most helpful thread and he knew exactly what to do. He used his ball joint tool, similar to the Harbor Freight tool as shown above. Took him about four hours to complete both sides.

All of the bolts took grease, as they should, and the system worked fine. I could not tell any difference in ride quality, as my trailer came from the factory with the EquaFlex system. It still was as smooth as silk. I now have the comfort of knowing the bushings will never wear out and can now be lubricated.

Our trailer is a 2010 and had about 6K miles on it. The nylon bushings were still in OK, but starting to wear a little. Probably if my trailer were heavier, they would have shown more wear.

Just a note, the lady at TrailAir was most helpful and courteous. And extremely knowledgeable. Great customer service!

Mike

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-20-2010 03:26 PM

Was all pretty straight forward. Trailer is at same height it was before--shackles were the same length and equalizer was the same. This one gets, at least at this point, and A+++. I wouldn't have known about it or tackled it if it weren't for this post.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-18-2010 05:35 PM

Turk2500

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-18-2010 01:28 PM

RetchedOne wrote:

I think i see what your saying, but if i dont catch this, and install the equalizer, will it be bad?

It would mean that your tires could possibly rub on the top by touching the top inside surface of the wheel well if you hit a large bump or drove over a curb. I really doubt though that your trailer has the taller equalizers like Turk2500s does.

When you get the kit, compare the two equalizers like the picture posted by Turk2500 and see. Then you could run one wheel up on a ramp or lift one axle with a jack (put the jack under the spring hanger plate - NOT under the axle itself) and see how much clearance you have over the top of the tire. Compare that number with the difference in the two (if any) and that should tell you if they will work or not.

Barney

Hensley "Arrow" 1400# hitch (Sold)

Not towing now.

Former tow vehicles were 2016 Ram 2500 CTD, 2002 Ford F250, 7.3 PSD, 1997 Ram 2500 5.9 gas engine

- 1978 Holiday Rambler - 12V DC problems - no lights in Technical Issues

- Will Air bags make a big difference? in RV Tips & Tricks

- dingy induced sway in RV Tips & Tricks

- Simple and inexpensive roof vent modification (Vent Covers) in DIY Maintenance

- Recent cost to install solar by an RV tech/shop??? in Technical Issues