- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- Cargo carrier and tongue weight reduction??????

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Cargo carrier and tongue weight reduction??????

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-22-2015 05:26 PM

Blue Ox Avail

BrakeBuddy Advantage

2015 Malibu

"Get busy living, or get busy dying."

Andy Dufresne, The Shawshank Redemption

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-28-2015 08:55 PM

On 10/26/15, Gdetrailer wrote:

If you look closely you will notice that the axles are 2/3 the way back from the front (IE tongue)..

If you place 100 lbs on the rear bumper your will remove 1/3 of that weight from the tongue or roughly about 33 lbs..

On 10/28/15, Gdetrailer wrote:I agree with the first sentence of the first quote -- the axles are about 2/3 of the way back.

Using 1/3 of the weight added to the rear as being the amount removed from the tongue I mentioned WILL be close enough.

The OP's trailer is about 27' long.

Using your 2/3 rule of thumb, would put the axles about 18' behind the ball.

The example in my first post put the axles at 17.8'.

I assumed the center of the cargo carrier would be 1.5' behind the rear of the trailer, putting it at 28.5' from the ball -- about 10.5' behind the axles.

I guess we have a fundamentally different understanding of how an old fashion "teeter totter" works.

My understanding is that 100# placed 10.5' from the fulcrum would be balanced by about 58# placed at 18' on the other side of the fulcrum.

Your understanding seems to be that 100# placed 10.5' from the fulcrum would be balanced by about 33# at the other end.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-28-2015 06:30 PM

let's say the "real" load changes to 900# when cargo is added.

Let's say a scale with 2000# capacity and accuracy of 2% of full scale (40#) is used to provide an indication of these real loads.

The "indicated" load with no cargo might be 960# or 1040#, or it might be 1000#.

The "indicated" load with cargo at the rear of the TT might be 860# or 940#, or it might be 900#.

If you're interested in the amount of "tongue weight reduction", the calculated difference between the "no added cargo" indicated load and the "added cargo" indicated load might be as low as 960-940 = 20# or as high as 1040-860 = 180#.

The scales readings could give errors of +/- 80% versus the "real" difference of 100#.

OTOH, they might be accurate to within a few pounds -- but how are you going to know?

Seems to me you might as well use an estimate based on a formula.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-28-2015 04:58 PM

"...An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." Col. Jeff Cooper

Sunset Creek 298 BH

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-28-2015 04:48 PM

Ron Gratz wrote:RinconVTR wrote:Absolute accuracy??? I guess that depends on your definition of "accuracy".

A tongue weight scale runs around $130. It will answer the question, with absolute accuracy, and no estimations.

There are several threads and many posts on ORF discussing the accuracy of one particular tongue weight scale.

This thread is just one of them.

I suggest anyone who thinks they can get "absolute accuracy" with a tongue weight scale should read the user comments.

Perhaps the simple formula offered by TundraTower in this post (as requested by the OP), reduced by 10% to account for the effect of axle spacing, will produce an estimate which is more accurate than the reading from an "absolutely accurate" tongue weight scale.

Ron

Ron,

With all due respect I would have to agree with RinconVTR on this.

I really do not think that the OP was looking for a way to calculate the exact change in tongue weight down to a fraction of an ounce..

While you are very welcome to show off your mathematical prowess it is not needed or as complicated as you are making it to be.. The OP (like I was at one time) is looking for any GREAT MASSIVE changes in the tongue weight for a given amount of weight added to the rear bumper..

Typically you do not need to know the exact weight to the ounce of what the tongue weighs, really a "ballpark" number can suffice..

Given you have tongue weights of 400-1,000 lbs or more you can have a acceptable error range of + (-) 10 or even 20 lbs..

It will never hurt a thing for trailer stability as long as you don't go under 10% AND provided long as your trailer tongue weight is not already on the tippy top brink of overload of your vehicle you have nothing to worry about.

What you are really missing is something called Center Of Gravity (AKA COG).. Your calculations are missing that and that will give you massive errors when driving down the road..

COG is a dynamic measurement and it messes with the tongue weight as you are towing..

Think of a trailer as a old fashion "teeter totter".. The tongue on one end , the rear of trailer on the other and your axles are placed in between..

The tongue weight IS fluctuating while your are driving down the road.. As the tongue goes up the COG shifts towards the rear and the tongue goes down the COG shifts towards the front. Your calculations are only good for a dead stop standstill..

Typically for bumper pull trailers the axles ARE placed using the "60/40 rule" or the "2/3 rule".. In other words the axles are placed at 60% from the front which will be 40% from the rear.. That IS the same as axles are 2/3 back from front and 1/3 from the rear.

This rule is pretty much across the board used for all bumper pull trailers in the North American part of the world.. It IS the recommended placement per Dexter and other axle manufacturers..

Using the info I posted you "dissed" earlier for ALL intents and purposes IS "accurate" enough for the OP to determine if the weight they plan to add to the rear will remove TOO much weight from the tongue..

Using 1/3 of the weight added to the rear as being the amount removed from the tongue I mentioned WILL be close enough.

As far as you "dissing" the Sherline scales, I don't have one, instead I use the bathroom scale method.. It works very well.

Sherline scales accuracy depends on PROPER placement of the scale, you MUST place it correctly under the ball part of the coupler.. Any other placement will introduce errors.

I also took multiple measurements then averaged them, this way I could rule out possible read errors or scale errors.

I also checked my bath scales against a shipping scale which is used for shipping freight via UPS/Fedex and even large bulk freight shipping companies (pallets).. I calibrated my scales so they would be as close to possible to known scales that have been verified as accurate.

The silliness of where this thread has gone is just unbelievable..

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-28-2015 04:27 PM

Ron Gratz wrote:RinconVTR wrote:Absolute accuracy??? I guess that depends on your definition of "accuracy".

A tongue weight scale runs around $130. It will answer the question, with absolute accuracy, and no estimations.

There are several threads and many posts on ORF discussing the accuracy of one particular tongue weight scale.

This thread is just one of them.

I suggest anyone who thinks they can get "absolute accuracy" with a tongue weight scale should read the user comments.

Perhaps the simple formula offered by TundraTower in this post (as requested by the OP), reduced by 10% to account for the effect of axle spacing, will produce an estimate which is more accurate than the reading from an "absolutely accurate" tongue weight scale.

Ron

Enough already Ron. A scale will get you a real weight, even if its not "absolutely accurate" in terms of science and engineering with calibration certification. E...nough.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-28-2015 01:36 PM

RinconVTR wrote:Absolute accuracy??? I guess that depends on your definition of "accuracy".

A tongue weight scale runs around $130. It will answer the question, with absolute accuracy, and no estimations.

There are several threads and many posts on ORF discussing the accuracy of one particular tongue weight scale.

This thread is just one of them.

I suggest anyone who thinks they can get "absolute accuracy" with a tongue weight scale should read the user comments.

Perhaps the simple formula offered by TundraTower in this post (as requested by the OP), reduced by 10% to account for the effect of axle spacing, will produce an estimate which is more accurate than the reading from an "absolutely accurate" tongue weight scale.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-28-2015 12:24 PM

scbwr wrote:

I'm adding a lightweight cargo carrier to the rear of my travel trailer by having a receiver welded on to the frame. So, the carrier will weigh 28 lbs. (unloaded) and I wouldn't carry more than 200 lbs. of cargo on it. Is there a mathematical formula that can be used to determine how this will reduce the tongue weight? My trailer, fully loaded for travel is 6500 lbs. Will adding 230 lbs. in back of the bumper reduce the tongue weight to cause a problem or require tweaking the WD hitch? Thanks for any help you can provide!!

This thread got real ridiculous...real fast.

A tongue weight scale runs around $130. It will answer the question, with absolute accuracy, and no estimations.

I have a lighter TT, running 4300-4500 depending on what we load. I added a hitch to the bumper and an aluminum rack with a very large plastic storage container bolted to it. I pack it with bottles, chainsaws, generator...you name it. 150 for sure-200lbs tops. My tongue weight, via actual tongue weight scale, changed very little. Unfortunately, I dont remember the exact number, but it was very low.

The bigger concern is balance. Smaller trailers like mine can get upset and begin to sway if there is too much hanging off the rear of the trailer. I came no where close IMO, as I could not sense any difference while towing.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-28-2015 11:47 AM

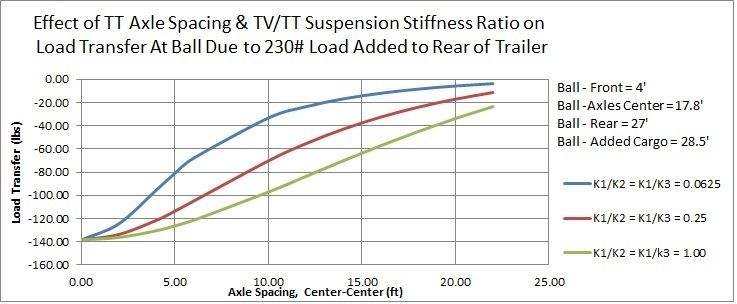

mosseater wrote:Yes, spring compression does come into play. This post will attempt to answer the "how much"?

There seems to be a law of diminishing returns, though, because at some point, more weight doesn't equal proportional reductions of tongue weight. Not sure if spring compression comes into play or what. It will help, just a question of how much.

There are three sources of springiness to be considered:

1) the upward displacement of the ball as load is decreased,

2) the downward displacement of the TT's front axle as load is increased, and

3) the downward displacement of the TT's rear axle as load is increased.

These three load-displacement relationships will have to be estimated because there is little or no data available to quantify them.

The load-displacement relationship at the ball (let's call this "K1") mostly is determined by the stiffness of the TV's rear suspension.

Some owners of 1/2 ton trucks have reported a TW of around 1000# causes the ball to drop about 4" when no WD is applied.

Based on this information, let's assume a value of K1 = 1000/4 = 250#/inch.

Based on information provided by Dexter axle, their Torflex axles with 2300-4000# capacity drop about 4" when fully loaded.

If this is typical for other axles, let's assume the stiffness for these axles is 4000/4 = 1000#/inch.

Let's call the front axle stiffness, "K2", and call the rear axle stiffness, "K3", and assume K2=K3.

The effect of suspension stiffness on load removed from the ball actually is dependent on the ratios of K1/K2 and K1/K3.

Using the values proposed above, we have K1/K2 = K1/K3 = 250/1000 = 0.25.

For these assumptions, each TT axle is four times as "stiff" as the springiness at the ball.

The graph below shows the effect of suspension stiffness for K1/K2 = K1/K3 ratios of 0.0625, 0.25, and 1.0. This range should cover the suspension stiffness ratios for virtually all TV/TT combinations.

For dual axle TTs, if the TV's rear suspension stiffness decreases relative to the TT axles' stiffness, the amount of load removed from the ball will decrease.

For this example and a TT axle spread of 5', if the stiffness ratio decreases from 1.000 to 0.0625 (a factor of 16), the load removal decreases from 126# to 81#.

In short, reducing the TV's vertical stiffness at the ball by 1600% relative to the TT axle stiffness caused a 36% reduction in amount of load removed from the ball.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-27-2015 02:42 PM

The OP wanted to predict changes in tongue weight due to weight added to the back of the trailer. You are right in that you do not need F1 for that analysis.

In my work this summer I was trying to predict how much of the WDH load is transferred back to my trailer axles, and it was that load transfer that I had in mind when I was looking at your formulas. But again, you don't need that for the OP's answer.

We pull a TT that weighs 7600 lbs total that sits on two 3500 lb axles. While it doesn't bother me to overload the Tundra chassis by 3-400 lbs, those trailer axles are built to a price point and are easily the weakest link in our rig. We replaced all the tires with the highest load range 5 weeks after the unit was delivered because they were going to be running right at their load limit.

I actually have a spread sheet that calculates all the axle and tongue loads based on what we put where, and everything that goes into the rig gets weighed (drives my DW nuts - an added bonus). If we get too close to the axle limits I'm going to move something to the truck bed or leave it home. Yeah, I'm compulsive about the load on my trailer axles.

Anyway, perhaps we've saved some brain cells today. At least this was more engaging than watching I Love Lucy reruns. Happy trails!

2014 Forest River Cherokee 264

Prodigy II / Equalizer 10K

103 nights & 12,700 miles since April '13

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-27-2015 01:45 PM

TundraTower wrote:The load applied to the A-Frame usually is established by trial and error -- changing ball mount tilt and/or number of chain links under tension (or raising/lowering L-brackets in case of Equal-I-zer).

1. You summed the moments around the axis of the coupler ball, but in order to create a load at the WDH ell brackets (F1 in your equation) the WDH hitch has to be engaged and the tongue jack retracted. When you do that the truck and trailer become one rigid member and you then have to consider the loads at the TV wheels in this sum of the moments and the equation has two more elements.

2. Where were you going to get the constant F1, the load applied to the A frame by the WDH ell brackets? This was exactly the point of my comment - we don't know that number.

When the desired amount of load transfer is achieved, you have established the value of F1 without needing to know its value.

When the bars are engaged and you retract your tongue jack and everything settles, a good bit of the classic tongue weight on the ball is transferred back to these L brackets PLUS a moment force is created at the hitch (about 750-800 foot lbs for my case) which is what forces weight back to the TV front wheels.Actually, the magnitude of downward force on the L-brackets (or lift chains) is considerably more than the tongue weight.

In my example, it was necessary to transfer 250# to the TT's axles to cause the desired 500# to be transferred to the TV's front axle.

Let's assume the distance from TV rear axle to ball is 60" and the distance from ball to TT axles midpoint is 200" (giving the assumed rear axle to TT axles distance of 260").

Also, let's assume the distance from ball to L-bracket or lift chain is 30".

Then, the formula, F2 = F1*d1/d2, can be changed to F1 = F2*d2/d1 = 250*200/30 = 1667# (total for 2 WD bars).

The combined bar force acting over the moment arm of 30" generates a moment of 1667*30 = 50,000 lb-in.

The downward force of 1667# on the A-frame is balanced by the 250# which was transferred to the TT axles and by a downward force of 1667-250 = 1417# added to the ball.

At the same time, the front ends of the WD bars push upward against the ball mount with a combined force of 1667#.

The upward force of 1667# minus the 1417# which was added to the ball yields a net upward force of 250# acting on the hitch head.

This 250 acting over the assumed rear axle to ball distance of 60" yields an additional moment of 250*60 = 15,000 lb-in.

Adding the 50,000 lb-in of direct moment plus the 15,000 lb-in from net upward force on hitch head gives a total moment about the TV's rear axle of 65,000 lb-in.

Dividing this moment by the 130" wheelbase gives a load of 500# added to the front axle.

This simply shows that WD load transfer calculations can be done in more than one way.

The method I outlined in my previous post treated the combined TV and TT as a single body with external forces acting at 1) TV front axle, 2) TV rear axle, and 3) TT axle(s).

The method presented in this post, follows your model of treating just the TV and hitch with a moment input and a force input applied to the hitch head and vertical reactions at the front and rear axles.

There is no best way of approaching the problem -- as long as all approaches give the same (correct) result.

The force transferred to the ell brackets as things settle from unloaded to loaded state depends on the spring rate of the WDH bars and the spring rate of your truck suspension, neither of which is linear, and neither of which is really known by us.The spring rate of a WD bar is essentially linear -- as long as you don't exceed the elastic limit. However, linear or not doesn't make any difference because you adjust the WDH to give the desired results -- the bars bend as much as they need to bend.

The spring rate of the truck suspension also doesn't make any difference. With only two axles, you have a completely deterministic system and displacements don't enter into the calculations.

Ron, please don't take offense at the comments. This is an absolutely fascinating analysis. I'm 42 years out of college but it is still just Statics 101, and I recognize I may be making it more complicated than it is as we try to visualize the free body diagram and forces around the WDH.---I thoroughly enjoy receiving intelligent comments such as yours. I almost always learn something new when answering (or trying to answer) someone's questions.

Also, I'm 47 years out of college and my aging brain cells need all the exercise they can get.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-27-2015 11:12 AM

RON - Thanks for the WD hitch analysis, but there are a couple of questions in that analysis that go to my previous point. Referring to the first equation reproduced below (I can't figure out how to copy and paste here):

1. You summed the moments around the axis of the coupler ball, but in order to create a load at the WDH ell brackets (F1 in your equation) the WDH hitch has to be engaged and the tongue jack retracted. When you do that the truck and trailer become one rigid member and you then have to consider the loads at the TV wheels in this sum of the moments and the equation has two more elements.

- We had a flat on the front of our TV in Oklahoma this summer and a 4 ton jack would not lift the front corner of the TV. If finally dawned on me I was trying to lift the entire truck about the trailer axle axis. I disengaged the WDH bars and then was able to jack up the front corner of the TV with normal effort

2. Where were you going to get the constant F1, the load applied to the A frame by the WDH ell brackets? This was exactly the point of my comment - we don't know that number.

When the bars are engaged and you retract your tongue jack and everything settles, a good bit of the classic tongue weight on the ball is transferred back to these L brackets PLUS a moment force is created at the hitch (about 750-800 foot lbs for my case) which is what forces weight back to the TV front wheels.

The force transferred to the ell brackets as things settle from unloaded to loaded state depends on the spring rate of the WDH bars and the spring rate of your truck suspension, neither of which is linear, and neither of which is really known by us.

Ron, please don't take offense at the comments. This is an absolutely fascinating analysis. I'm 42 years out of college but it is still just Statics 101, and I recognize I may be making it more complicated than it is as we try to visualize the free body diagram and forces around the WDH. In my case I decided the theoretical analysis was 80% of the work for an answer that is only 20% more correct. That's why I weighed mine in various states and determined the moment created by the WDH with field data, and now just apply that as a constant in my spreadsheet that calculates tire/axle loads as I load the trailer and truck. It isn't exact for every situation, but it is close enough.

Again, If I'm missing something or making this overly complicated, I welcome your insight. No flames were intended.

- - - - - - - - - - - - - - - - - -

Estimating load transfer via a WDH doesn't get any simpler than the following.

Let:

F1 = combined downward force exerted on A-frame at WDH lift brackets

F2 = downward load added to TT axles

d1 = distance from ball to WDH lift brackets

d2 = distance from ball to axles' midpoint.

Then:

F2 = F1*d1/d2

2014 Forest River Cherokee 264

Prodigy II / Equalizer 10K

103 nights & 12,700 miles since April '13

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-27-2015 07:42 AM

scbwr wrote:Using a TW scale or using a CAT scale will provide an estimate of TW changes.

I appreciate the responses. I've pretty much decided to buy a tongue weight scale sometime over the winter and then I can get an accurate reading with whatever I put on the rack. I'll get a baseline reading by measuring the tongue weight with just added weight of the hitch being welded to the trailer frame. Then I can see how it changes with the empty rack added, and then with cargo added to the carrier. If I have any problems, I'll take the trailer back to the CAT scales and get an updated weight of the trailer alone, so I'd really know exactly what the tongue weight is as a percentage of total weigth.

However, don't be fooled into thinking that you can measure TW changes with an accuracy of 1# or even 10#.

To get an estimate of change in TW, you'll need to subtract two readings -- each of which might have an error of +/- 25# if using a Sherline or +/- 20# if using CAT scales.

You'll be lucky if the difference is within 20# of actual and shouldn't be surprised in it's off by 40# or more.

Given the information you've provided and assuming your TT has an axle spread of 5', I believe it's reasonable to expect a TW reduction equal to about 55% of the weight of cargo carrier and its cargo.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-27-2015 06:38 AM

Blue Ox Avail

BrakeBuddy Advantage

2015 Malibu

"Get busy living, or get busy dying."

Andy Dufresne, The Shawshank Redemption

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-26-2015 07:11 PM

Ron Gratz wrote:Gdetrailer wrote:In the example I used, the distance from ball to added load was 28.5' and distance from ball to axles' midpoint was 17.8'.

If you look closely you will notice that the axles are 2/3 the way back from the front (IE tongue)..

If you place 100 lbs on the rear bumper your will remove 1/3 of that weight from the tongue or roughly about 33 lbs..

That puts the axles' midpoint at 17.8/28.5 = 62% of overall length.

If the TT had a single axle at 17.8',

100# added at the rear would cause about 100*0.38/0.62 = 61# to be removed at the ball.

In your example where "the axles are 2/3 the way back from the front" (and if the trailer is single axle),

100# added at the rear would cause about 100*0.333/0.666 = 50# to be removed at the ball.

In order to remove a load of 33#, the axles would have to be 3/4 of the way back -- not 2/3.

Ron

Well Ron, I have very bad news for you..

I have PERSONALLY weighed the tongue weigh difference using my 26ft dual axle TT and the result IS what I have mentioned above.

for 100 lbs my tongue LOST 33 lbs..

I also tested 200 lbs and the result was pretty darn close to 66 lbs..

Typically your axles ARE at 1/3 from the back and two thirds from the front in order to get proper 10%-15% tongue weight balance.

The dual axle tends to foul up calculations since the center is between the two axles and your axles do shift front to back a bit..

In other words measurements are a bit dynamic even when sitting still..

Additionally COG can affect the tongue weight which is an often overlooked item.. COG will shift some weight to the tongue if tongue is lower than level and if above level it is shifted towards the back..