- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- EMS Installation Question

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

EMS Installation Question

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-02-2015 05:07 AM

I could remove the metal box as well and just set the EMS there could I not?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-04-2015 07:22 AM

myredracer wrote:GrandpaKip wrote:

If you think about contact area of electrical connections, all you really need is the equivalent of the cross section of the wire. I would be more concerned with the capture ability of the flat spots. A simple way around that is to whack a flat spot in part of the wire to sit on the flats.

I suppose you could do that and may be better than not doing anything, but stranded would still be best. Hammering copper conductors isn't exactly standard industry practice...

I agree about the stranded wire. Any wiring I do in the camper is stranded, AC or DC.

A slight flat spot also keeps the wire from rolling to one side in some lugs when tightening.

2015 Skyline Dart 214RB

2018 Silverado Double Cab 4x4

Andersen Hitch

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-04-2015 05:01 AM

Hi Don;

You can use Romex. For the ground wire, don’t use the crimp end, but bend it to the right screw down on it.

No need to use the junction box.

Dave

David J. Kurt

Customer/Technical Support

Progressive Industries

1020 Goodworth Drive

Apex, NC 27539

919-267-6948

Fax: 919-267-6975

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 10:19 AM

hawkeye-08 wrote:

I plan on installing one of these in next few years myself so have been reading with interest.

Here is what I have learned, there are several ways to accomplish this that will work. The best way may be stranded wire, but solid will work. I would also suggest checking connections on EMS annually to ensure things have not loosened up...

The more I read the better I like having my ems. Another place I keep an eye on is the converter stranded battery cable set screw lugs. It's surprising how hot they get even when tight. My PD hasn't been bad but I had a wfco for a short time and it seemed worse. You can only tighten it so much or its going to break.

It's a weak point in the engineering of it. imo

Seems like a crimped lug and a stud would be better. Just like at the other end on the battery.

But then again they are used in set screw lug applications all the time so it's a weak point on the board?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 09:49 AM

Here is what I have learned, there are several ways to accomplish this that will work. The best way may be stranded wire, but solid will work. I would also suggest checking connections on EMS annually to ensure things have not loosened up...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 07:58 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 07:38 AM

" Yep, that is pretty much the standard for RV manufacturers. But if you inspect them, you can often find many of the them that should be tightened more and some that do not have the wires twisted together very well. I doubt that the factories used licenced electricians and from what I've seen in some cases, not much training at all and they certainly don't take whatever time is needed to do a thorough/professional job. "

LOL, that pretty much describes most of the RV!!!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 07:34 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 07:34 AM

GrandpaKip wrote:

If you think about contact area of electrical connections, all you really need is the equivalent of the cross section of the wire. I would be more concerned with the capture ability of the flat spots. A simple way around that is to whack a flat spot in part of the wire to sit on the flats.

I suppose you could do that and may be better than not doing anything, but stranded would still be best. Hammering copper conductors isn't exactly standard industry practice...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 07:25 AM

number 4 solid used in panels with set screw connectors. 170 amps

Solid

Set screw connected 170 amps

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 07:13 AM

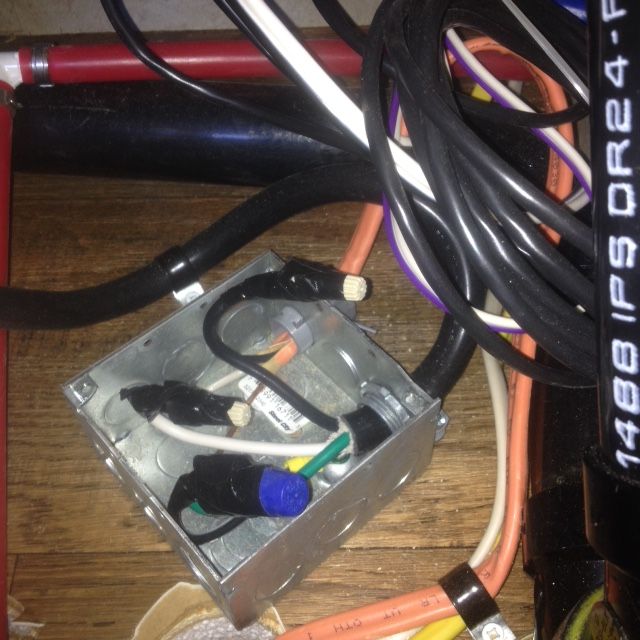

ems install

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 07:08 AM

2015 Skyline Dart 214RB

2018 Silverado Double Cab 4x4

Andersen Hitch

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 07:02 AM

rjxj wrote:

Zero stranded to solid but it's not a problem if you need to do it. Stranded to solid is used in many 120 v applications such as can lights etc. but I think this is what we are talking about: Yes you will find stranded in places like light fixtures but they are light gauge conductors and carry low current. Nevertheless, making a good stranded to solid connection with a twist-on wire nut is harder than solid to solid, esp. in larger wire gauges like the #10. I've seen a lot of bad stranded splices in light fixtures and larger gauges over the years.

He wont have stranded to solid either. He will have the existing solid from the panel to the EMS and solid from the EMS to the furrion connector. All romex will be stationary and secured like the rest of the romex inside the rig. He's using the original cord with a new furrion end from his rig to the pedestal. If he is planning to connect #10 solid to the line and load lugs inside the EMS, I stand by my assertion that it's better to use stranded wire, but that's just my professional opinion as an EE.

Solid wire in set screw lugs is very common. Yes it certainly is, but as in my previous post, the design and contour of lugs in circuit breakers is different and provides better contact surface area.

His original junction box had stranded to solid in it from the manufacturer, with wire nuts. Yep, that is pretty much the standard for RV manufacturers. But if you inspect them, you can often find many of the them that should be tightened more and some that do not have the wires twisted together very well. I doubt that the factories used licenced electricians and from what I've seen in some cases, not much training at all and they certainly don't take whatever time is needed to do a thorough/professional job.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 06:15 AM

myredracer wrote:rjxj wrote:

That's interesting. Every connector in my house panel from 15 to 60 amp uses a screw connector with solid wire.

How many #10 splices have you got that are actually stranded to solid? Solid to solid is a different matter. Plus being in an RV that is subject to vibration and wide temp. swings is different than in a house.

Where would you have a 60 amp connector (wire nut) in a house?

Zero stranded to solid but it's not a problem if you need to do it. Stranded to solid is used in many 120 v applications such as can lights etc. but I think this is what we are talking about:

" I recommend against connecting #10 solid wire directly to the lugs of the EMS and only use stranded."

He wont have stranded to solid either. He will have the existing solid from the panel to the EMS and solid from the EMS to the furrion connector. All romex will be stationary and secured like the rest of the romex inside the rig. He's using the original cord with a new furrion end from his rig to the pedestal.

Solid wire in set screw lugs is very common.

His original junction box had stranded to solid in it from the manufacturer, with wire nuts.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-03-2015 05:58 AM

rjxj wrote:

That's interesting. Every connector in my house panel from 15 to 60 amp uses a screw connector with solid wire.

If you are referring to a wire nut (aka marrette) how many #10 splices have you got that are actually stranded to solid? Solid to solid is a different matter.

If you are talking about a circuit breaker, look very closely at them and you will see a different profile to the lugs like in this pic which is a residential 15A brkr. Note the concave shape on each of the two contact surfaces of the lug. The lug in the EMS is basically flat on at the contact points.