- Good Sam Community

- Groups

- Truck Camper Group

- Forum

- Re: Happijac lubrication

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Happijac lubrication

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-17-2009 07:37 PM

First you have to make a little tool like this. An old hanger works good. This will serve two purposes, explanations following.

Remove the two screws that hold on the motor.

Pull the motor off the jack.

Pull out the spring loaded socket.

Remove the lever and pin...a pair of flush wire cutters works well. Wedge them underneath and they pop right out.

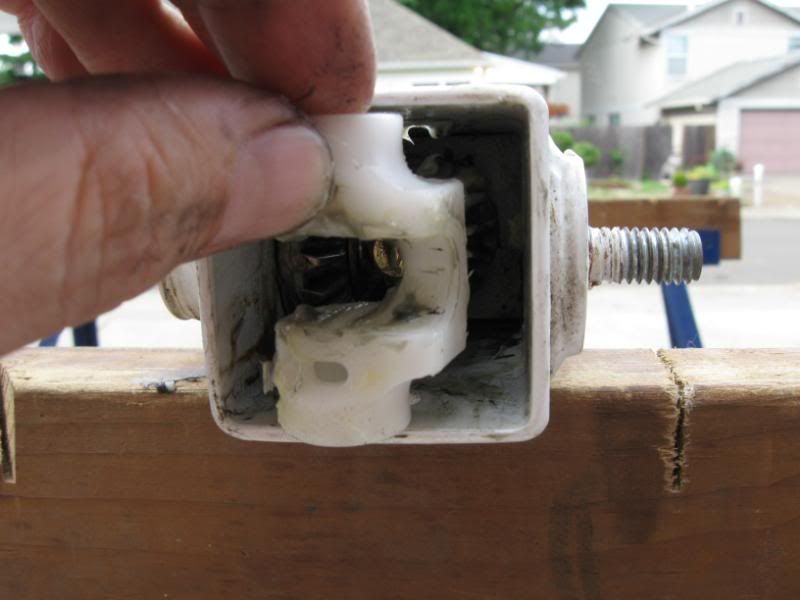

Remove the internal plastic manual mechanism...note how this is installed. one side has a round hole and the other an oval shape where the lever goes.

There is a "C" clip here, you need to remove it with the little tool you made. Just put it in from the side and pull back. It will pop right out.

Once you get the clip off then pull out the manual socket.

This is the hole in the socket that is to be oiled, but as you can see in the next few pics, the only thing that is being lubed is the socket itself.

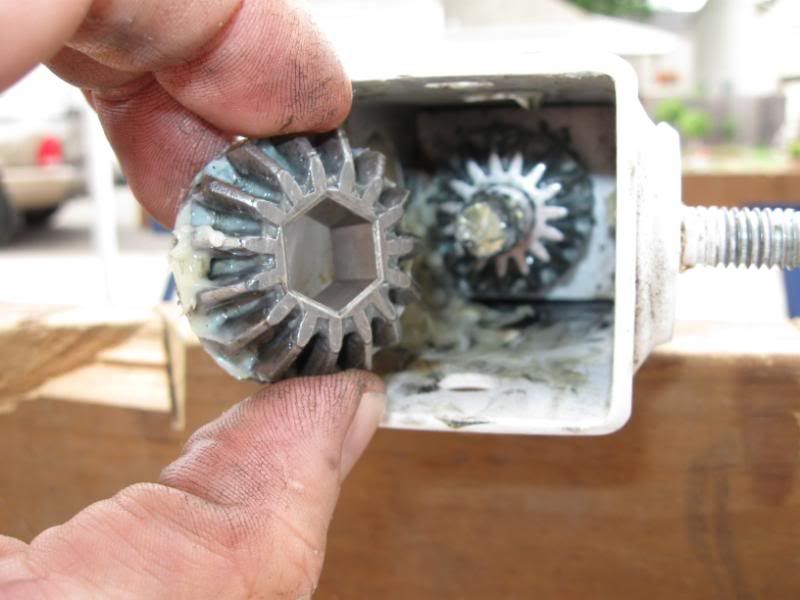

Once you pull out the socket, remove the manual gear.

Now as you can see the oil really goes nowhere. There is actually a lot of grease here. What your going to do next is pull this gear off that shaft straight towards you. Use that tool again to hook the gear from behind and pull it. You may have to do it a few times, the shaft gets a little burr on it but if it gets stuck ,just push it down and keep yanking, it will come off!

Once the gear comes off, this is what the back looks like. It has two slots. The slot that has the closed ends is what holds the pin in place. IT IS IMPORTANT YOU PUT THIS BACK TOGETHER THE WAY IT COMES APART!

Rotate the shaft so the pin is facing towards the corner and pull it out.

Now pull the leg assembly out of the jack housing.

Get ready to inspect and re lube.

Pull this cinch spring off and inspect this bearing.

Use an air ratchet or drill to turn the worm screw all the way out, inspect and re lube.

Re-assembly is just the opposite of the tear down. I found that even though this jack was sticking on me, it was still pretty well lubed, but maybe not enough.....Hope this dispels any unknown facts as to how these things work. One other note is that if the worm drive of the leg was to wear out...seems like you should be able to replace it rather than the whole jack. MMMMMM...haven't got to that yet but I wonder if they sell it seperatly? Does any one know?

- Labels:

-

Truck Campers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-29-2013 04:14 AM

Mine were in bad shape and I discovered a broken cinch spring in one upper unit. I will be ordering parts from Happijac as soon as I get back from Colorado.

2005 Outfitter Apex 8

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-20-2013 02:34 PM

I will take them apart next year and see how it is. Once you get use to do it, it takes maybe 1 hour to remove, apart, rebuit, install.

Bigfoot 2008, 10.4, F350, 2006, Diesel 6.0, Black, 4x4, long box, Air lift, Rancho 9000, Rear sway bar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-20-2013 01:07 PM

I have used 4 coats of ZEP wax for my inner tubes. Made a horrible mistake coating them with light oil.

I believe there is a probability of capillary action working moisture up the inner tube from the ground. One of my 2002 vintage 4150's had rusted inside the outer tune and outside the inner tube quite badly. Could be the weather here in Ontario.

Just working on my first teardown of a 4150...all because of the generous sharing of knowledge here on this forum. Thanks all.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-19-2013 06:01 AM

Bigfoot 2008, 10.4, F350, 2006, Diesel 6.0, Black, 4x4, long box, Air lift, Rancho 9000, Rear sway bar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-18-2013 06:34 PM

Kidoo wrote:

Just received the top assembly. One word of caution, the pin would not go in the top hole when trying to assemble the new unit. I took it appart, where the spring meet the two parts clutch, and there was TWO washers on one side of the bearing, very small washer but the pin would not go, took it off and no problem.

Did you contact Hjac to let them know about the issue?

I would be interested why they had 2 washers.

Did you just remove 1 washer?

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-18-2013 05:00 PM

Bigfoot 2008, 10.4, F350, 2006, Diesel 6.0, Black, 4x4, long box, Air lift, Rancho 9000, Rear sway bar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-29-2013 07:04 PM

This part is made of many little balls, I hope it will eventually all clear from the screw shaft. The other side is really smooth, not binding at all.

The rear 4150 jacks uses the ACME block instead of ball screw and the shaft is made a bit different with smooth groove, the front jack screw is a much smoother shaft.

I also took a look at the other outer tube today and 2 were also bent a little, not much, but I gave it a few wack to make them as straight as possible.

I ordered an upper assembly from Happijack because I cannot find the Clutch / Wrap spring. I will also buy some TC1018 thrust bearings and thrust washer and replace them on all jacks. I think these bearings should be cleaned at least every two years and relube and the o ring check to make sure they do not get destroyed, in all 4 of my shaft, the o ring where broken.

Bigfoot 2008, 10.4, F350, 2006, Diesel 6.0, Black, 4x4, long box, Air lift, Rancho 9000, Rear sway bar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-29-2013 06:01 PM

Kidoo wrote:

Just got the answer from Hapijac, they answered within a day! They sell the upper assy as a kit for 42 dollars. It includes all what is needed to fix the thing, bearing and washer, wrap clutch spring, connecting barrel and square plate.

They also sell everything else you need to fix your jack.

I am impressed! Kudos to Hjac!

It does seem that the rear jacks are a lot more reliable but they do not have to do the work that our front jacks do.

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-29-2013 03:04 PM

They also sell everything else you need to fix your jack.

Bigfoot 2008, 10.4, F350, 2006, Diesel 6.0, Black, 4x4, long box, Air lift, Rancho 9000, Rear sway bar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-28-2013 05:31 PM

MeyerzLance wrote:Kidoo wrote:

Hope the company will answer my request, otherwise I will not be a happy camper. Camper is only 5 years old without any abuse.

They sold me the parts I needed. Shouldn't be an issue

Thanks, that will make rebuild easier.

Bigfoot 2008, 10.4, F350, 2006, Diesel 6.0, Black, 4x4, long box, Air lift, Rancho 9000, Rear sway bar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-28-2013 04:41 PM

Kidoo wrote:

Hope the company will answer my request, otherwise I will not be a happy camper. Camper is only 5 years old without any abuse.

They sold me the parts I needed. Shouldn't be an issue

2007 Northstar

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-28-2013 01:15 PM

Bigfoot 2008, 10.4, F350, 2006, Diesel 6.0, Black, 4x4, long box, Air lift, Rancho 9000, Rear sway bar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-28-2013 12:45 PM

The o ring between the barrel and bottom of the head are also all torn apart. I believe it brakes up like that when you get them to snug when they are up, it probably squeze the o ring too much. This cause the o ring to get in between the screw and the head and it created lots of dragging.

HOpe the company will answer my request, otherwise I will not be a happy camper. Camper is only 5 years old without any abuse.

Bigfoot 2008, 10.4, F350, 2006, Diesel 6.0, Black, 4x4, long box, Air lift, Rancho 9000, Rear sway bar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-28-2013 06:19 AM

Bigfoot 2008, 10.4, F350, 2006, Diesel 6.0, Black, 4x4, long box, Air lift, Rancho 9000, Rear sway bar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-11-2013 07:32 PM

woodhog wrote:

Hi Jim...

I was also wondering what instructions they gave Devildog, I did mine the way you showed me and it worked very well...

There was talk that the company would not give our the instructions due to so called liability issues...

That is absolutely correct! We will have to wait on Devildog to tell us what Hjac said and actually what he did.

I will say this, after I lubed my jacks the first time I have been a happi jac guy. I have done them 2 times.

Almost 14 years now... and I use the cr** out of mine.

I have had to sand some places on the outside tubes from rocks chipping the paint and then rust sets in... Otherwise... No other problems.

Jim