- Good Sam Community

- Groups

- Fifth Wheel Group

- Forum

- Roadside Slide Failed

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Roadside Slide Failed

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-24-2015 03:14 PM

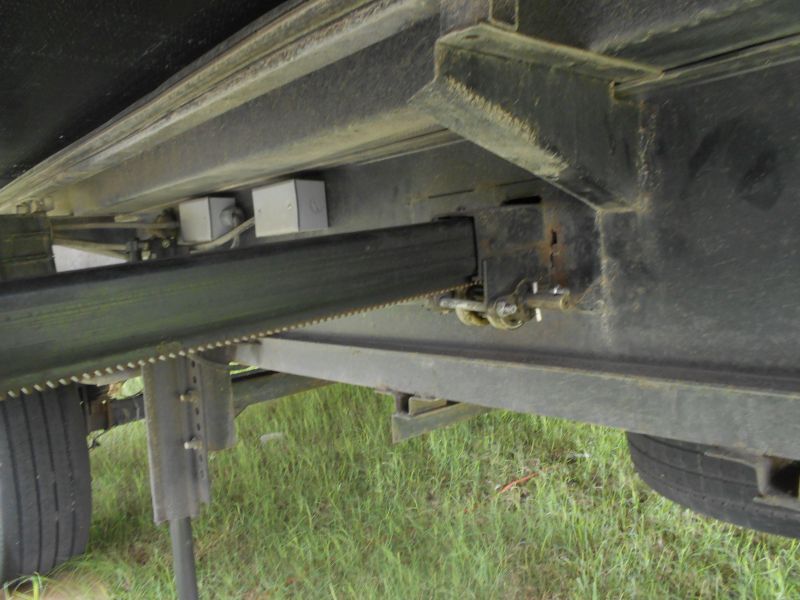

A week or so ago the long roadside slide, maybe about 20' long, started making lots of noise. I called a local dealer to come out and check it and made an appointment to get the RV in and repaired. Long story short, after about a week of seeing what the next failed part was going to be it turned out that one gear pack was completely stripped with the other two damaged. The weld on the middle rail of three had broken and one of the three rails had twisted. For those who don't know the way this works is that there are three rails with three gear packs that are tied together so that when one is pushed (or pulled) the other two turn with it. The push (and pull) is performed by a hydraulic cylinder.

For all you engineers out there, where would you put the hydraulic cylinder on a slide that is maybe 20' long with a French Door domestic refrigerator and a floor to ceiling pantry next to it and a TV on the other end? If you said that the hydraulic cylinder would be placed at a point determined to be the center of the weight on the slide you would be wrong. If you said that the hydraulic cylinder would be placed at the center of the slide you would be wrong. The hydraulic cylinder was placed about halfway between the rail at the opposite end of the slide from the refrigerator and pantry and the end of the slide. Its not even between the rails. Its about as far towards the end of the slide as it could possibly be installed.

Now am I crazy or would just about any reasonable person think that putting the hydraulic cylinder at the opposite end of the weight is a prescription for problems? Has anyone else had problems with a set up like this? Has anyone else have a similar system that works for them?

Thanks,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-30-2015 10:10 AM

taken wrote:

The design of having one hydraulic ram at one end (whether it's the heavy end or not, it's usually in the front) is completely normal. There is a shaft connecting the two gear packs keeping them turning at the same time. So, while it may look crazy, it's used all over the industry.

The washer trick is a band aid cure for a slide that is out of height adjustment. If the slide is adjusted correctly there should always be enough down force to keep the gear pack and the idler gears in mesh. The heads at the end of the idler tubes need to be adjusted down to increase the pressure on the idler tube while it is in motion going in and out. If Lippert advised anyone to do this, it's because they knew that telling them how to correctly adjust the slide would take time and if you don't do it correctly, you could throw things further out of adjustment.

What's causing the problem with your out of height adjustment scenario is, as the slide goes in, the weight of the slide is coming off the tubes too soon transferring to the floor of the RV. This is what's unloading the idler tubes and causing them to jump gears. If you look at the outside of your slide where your idler tubes meet the slide cross rail you will find the two adjustable heads. Each will have two bolts and nuts over slotted holes. The nuts/bolts lock them in place but when loosened can allow the head to slide up or down. Below the head is a long bolt with a set nut. This long bolt will raise or lower the head when it's set nut and the two previously mentioned nuts/bolts are loose.

Last summer my new rig had this very problem. When I brought it back to XLR to get it straightened out I talked extensively with one of Lippert's main techs who came to the plant to address my issue. He told me Lippert knows about the washer trick and they've also seen the gears cut off the bottom of the idler tube and welded on lower to try to scab a cure. None of this is correct. There is only one correct way and that is to align the slide in the trailer correctly. He said dealers, mobile techs, and do it yourselfers do this type of repair ALL the time but it just isn't the right way to do it and will likely lead to another failure in the future due to moving the stress to an area that it's not meant to be. He said he's always shocked that people go to such lengths to correct something but completely ignore the adjustments that are built into the system to cure this very issue...

That all makes sense. My understanding is that with ours, BTW the plunger is about 3' from the back of the slide, one of the rails, maybe the middle rail, was not perfectly square with the frame and gear pack causing the gears to wear. With that said it still makes no sense to me that the plunger would be placed at one end or the other of the slide when there is room at the center and its even closer to the pump.

Thanks for your reply.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-29-2015 12:44 PM

The washer trick is a band aid cure for a slide that is out of height adjustment. If the slide is adjusted correctly there should always be enough down force to keep the gear pack and the idler gears in mesh. The heads at the end of the idler tubes need to be adjusted down to increase the pressure on the idler tube while it is in motion going in and out. If Lippert advised anyone to do this, it's because they knew that telling them how to correctly adjust the slide would take time and if you don't do it correctly, you could throw things further out of adjustment.

What's causing the problem with your out of height adjustment scenario is, as the slide goes in, the weight of the slide is coming off the tubes too soon transferring to the floor of the RV. This is what's unloading the idler tubes and causing them to jump gears. If you look at the outside of your slide where your idler tubes meet the slide cross rail you will find the two adjustable heads. Each will have two bolts and nuts over slotted holes. The nuts/bolts lock them in place but when loosened can allow the head to slide up or down. Below the head is a long bolt with a set nut. This long bolt will raise or lower the head when it's set nut and the two previously mentioned nuts/bolts are loose.

Last summer my new rig had this very problem. When I brought it back to XLR to get it straightened out I talked extensively with one of Lippert's main techs who came to the plant to address my issue. He told me Lippert knows about the washer trick and they've also seen the gears cut off the bottom of the idler tube and welded on lower to try to scab a cure. None of this is correct. There is only one correct way and that is to align the slide in the trailer correctly. He said dealers, mobile techs, and do it yourselfers do this type of repair ALL the time but it just isn't the right way to do it and will likely lead to another failure in the future due to moving the stress to an area that it's not meant to be. He said he's always shocked that people go to such lengths to correct something but completely ignore the adjustments that are built into the system to cure this very issue...

TV - 2017 F350 SRW CC SB 4X4 6.7

TH - 2015 FR XLR 395AMP

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-29-2015 12:21 PM

view of where you need to place the washer for the stripped gear fix.

You can see the washer between the two tubes. Ideally I'd like to tack weld it in place. I will try this fix away from home so I'm going to try a small amount JB Weld in the washer hole and around the edges. I'll lay the washer on some wax paper and slide it into the gap. May have to use some paper shims until the JB Weld sets up.

[URL]

[URL]Tnx to Joe for the pics. Should have put jwakeman.

Crew Cab long bed 6.0 gasser 4.10

2019 Open Range OF337RLS

Yamaha EF3000iSE

retired gadgetman

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-28-2015 08:20 AM

Silver 05 Dodge RAM LB CTD Dually 4Speed Auto SWD 3.73, Westin Sportsman Grill & Taillight Guards,Husky Mudguards, Retractable Ball Hitch, Onboard Air & Horns, MaxBrake - towing 2005 Keystone Montana Big Sky 3670 with Star Performance adapter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-27-2015 05:50 AM

Crew Cab long bed 6.0 gasser 4.10

2019 Open Range OF337RLS

Yamaha EF3000iSE

retired gadgetman

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-27-2015 05:47 AM

2018 Cardinal Luxury Edition 3250 RLX

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-26-2015 09:00 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-26-2015 08:05 AM

Put the washer in the top of the guide channel to take out the slop.

Again sorry for the confusion.

2016 Montana 3721

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-25-2015 05:13 PM

wvcampers wrote:

The rams on my Cardinal are not in the center of the slides. I have not had any problems with the slides. I do have the fridge in one slide but not as large as yours. The Cardinal is 08 and gets lots of use.

Thank you for that. Do you have two rams? Ours has only one that is outside of the three gear rails about 3' from one end of the slide and about 17' from the other end.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-25-2015 01:45 PM

2018 Cardinal Luxury Edition 3250 RLX

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-25-2015 03:30 AM

laknox wrote:ThePostman wrote:jwakeman wrote:

Yes it is lippert. The front rams is in about a foot and the back is in about 3 foot. I am unable to locate the stuff FR sent me about the fix at this time

We only have one ram on a slide that is probably about 20' long and the ram is on the light end of the slide maybe three feet from the end.

I can't imagine =anyone= designing something like that. Lousy, lousy engineering. I totally agree with your analysis of the design.

Lyle

Exactly what I thought but the manufacturer and Lippert claim that there are many units out there just like ours that have never had a problem. I'm trying to verify that. BTW, the manufacturer is saying that they may pay at least some of the cost for moving the ram to the center of the slide.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-24-2015 07:46 PM

ThePostman wrote:jwakeman wrote:

Yes it is lippert. The front rams is in about a foot and the back is in about 3 foot. I am unable to locate the stuff FR sent me about the fix at this time

We only have one ram on a slide that is probably about 20' long and the ram is on the light end of the slide maybe three feet from the end.

I can't imagine =anyone= designing something like that. Lousy, lousy engineering. I totally agree with your analysis of the design.

Lyle

B&W OEM Companion & Gooseneck Kit

2017 KZ Durango 1500 D277RLT

1936 John Deere Model A

International Flying Farmers 64 Year Member

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-24-2015 07:19 PM

Crew Cab long bed 6.0 gasser 4.10

2019 Open Range OF337RLS

Yamaha EF3000iSE

retired gadgetman

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Nov-24-2015 04:14 PM

jwakeman wrote:

Yes it is lippert. The front rams is in about a foot and the back is in about 3 foot. I am unable to locate the stuff FR sent me about the fix at this time

We only have one ram on a slide that is probably about 20' long and the ram is on the light end of the slide maybe three feet from the end.