- Good Sam Community

- Everything RV

- Technical Issues

- Re: Planning Solar Panels

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Planning Solar Panels

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-22-2016 10:05 AM

I'm working on my very first DIY camper conversion, using a 2010 extended Ford E250.

I was looking at solar panels yesterday, I was going to make the move eventually but maybe sooner than I originally thought.

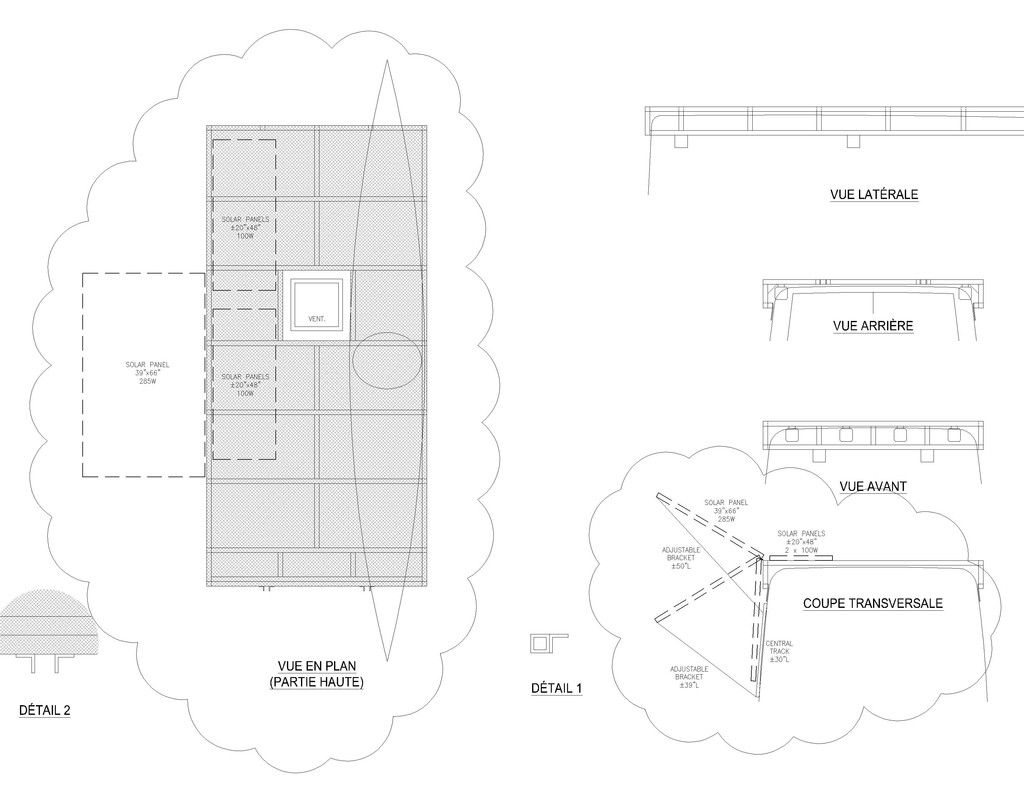

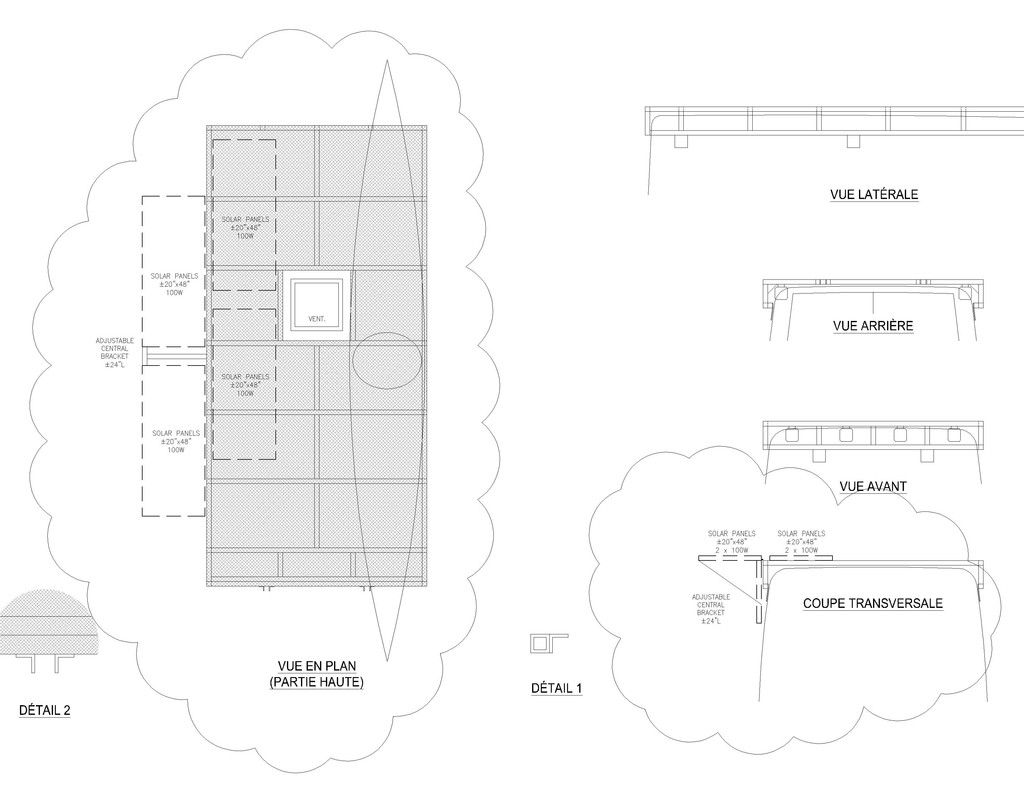

I just want to plan where the panels will be mounted on my roof rack and how many I needed, this is what I came up with.

I can fit a big 285W solar panel on the side of my van, with hinges on top and some sort of an adjustable bracket (see drawing)

I can also fit two smaller panels on the top of the roof rack but only in a specific area, I need space for my canoe or kayak on the right side and I can't put them too close to the rear which is the highest point of my van, as of now I have 2-3 inches of space when I back up through my garage door...

There probably is a 100W thin model I could install, around 20"x48" ish ?

Take a look at my roof rack drawing, I added the panels (clouds)

Also Is 485W of solar energy worth it? I don't know much about solar, I'll have two 6v golf cart batteries at 225AH.

My rig is fully equipped, 3 way fridge, microwave + convection, LED lights, pump, fans, AC + DC outlets...

I red that you can get more energy out of your panels by tilting them to face the sun.

Does anything exist on the market today to manually adjust the angle of a panel, I was thinking of adding a sturdy central bracket.

Thanks for any help! 🙂

DIY conversion build, extended 2010 Ford 5.4L E250 + high top, from Montreal Canada, new to all this so please be patient and clear with me (never built or camped in a van yet)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 03:25 PM

Almot wrote:

I don't see where the canoe rack is described. You mentioned panel mounted on the roof rack, so panels are approximately at the same height as canoe rack, only soft cradles are few inches higher. Normally people use 2"-3" high supports under gunwales. If you keep 10-12" distance from cradles to panel, I don't see this causing much problem.

There is no canoe/kayak rack, the roof rack's flooring is an aluminum wire mesh that you can walk on, I will tie the kayak down to it.

Maybe this picture will help.

On this picture the roof rack is not installed so it's a lot tighter fit, around 2" clearance on top, and like I mentioned earlier the highest part is the rear of the roof rack, that's why I can only add panels toward the front if they are 1.5" thick.

If I come out during the winter I have to make sure there is no snow on the ground near the door opening.

Ho and naturally I will put the kayak on top once I'm out of the garage.

DIY conversion build, extended 2010 Ford 5.4L E250 + high top, from Montreal Canada, new to all this so please be patient and clear with me (never built or camped in a van yet)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 12:07 PM

Array size and batteries:

There is a rule 1W per 1AH, but it should really be calculated individually because a lot depends on your usage pattern. 2*6V batteries @225 AH each need 45A max. 4*6V need 90A max. 500W solar will generate 35A max.

I think that you can have 4*6V with 500W because you will have an alternator in addition to solar. Also, if you conserve energy and use less than 85-90 AH a day with 4*6V, batteries will cycle in 80-100% SOC. At this point it only accepts low current and you will never need more than 20-25A.

Panel voltage is not the controller output voltage, or the battery voltage. This leads to discussion of 12V panels vs 24, PWM vs MPPT, and has been discussed here way too many times.

Single small panel has 18V, battery needs 13-14V. PWM controller understands only amps. It will cut the excess volts. These volts are lost. In other words, panel watts are lost.

MPPT controller transforms Watts into Amps W/V=I, where W is panel watts and V is battery voltage. If you have 570W, MPPT will transform 570/14 = 39A after controller losses. Doesn't matter - what voltage, series or parallel, it will still convert 570/14=39.

MPPT conversion comes with losses 4%-10%, losses are higher when you feed higher voltage, but these losses are not terribly high.

One problem with MPPT is that panel voltage drops in a hot weather. This doesn't matter for PWM because PWM cuts them off. But with MPPT these lower volts mean lower watts going into controller, so after conversion W/14=I the current will be lower.

You see now why people don't like discussing PWM vs MPPT. Many variables. The bottom line is - get more total wattage. The more, the better.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 10:38 AM

2oldman wrote:evy wrote:400w is usually pretty good for 2 batteries. of course it depends on your usage. Big inverters, running big appliances takes more.

What I meant was, is 400watts of solar worth all the trouble and money spent or will I barely get anything in return?

No, panel voltage don't have nothing to do with battery voltage.

I wanted to have the possibility of adding 2 other 6v gc2 225AH batteries in the future (near or far) 😕

DIY conversion build, extended 2010 Ford 5.4L E250 + high top, from Montreal Canada, new to all this so please be patient and clear with me (never built or camped in a van yet)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 10:02 AM

evy wrote:400w is usually pretty good for 2 batteries. of course it depends on your usage. Big inverters, running big appliances takes more.

What I meant was, is 400watts of solar worth all the trouble and money spent or will I barely get anything in return?

No, panel voltage don't have nothing to do with battery voltage.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 06:45 AM

https://www.amazon.com/gp/aw/d/B01AXU17UI/ref=mp_s_a_1_3?qid=1464010025&sr=8-3π=SY200_QL40&keywords=...

Basically I should build a kit myself? Heavier and longer wire gauge, better charge controller.

Also I'm guessing that panel voltage don't have anything to do with the battery voltage right? 24v vs 12v (2x6v) the charge controller will deal with that?

Just like my trickle charger charged my van's 12v battery from a 110v outlet all winter long in the garage.

DIY conversion build, extended 2010 Ford 5.4L E250 + high top, from Montreal Canada, new to all this so please be patient and clear with me (never built or camped in a van yet)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 06:18 AM

2oldman wrote:

French.. how exotic. What does 'worth it' mean to you?

French exotic? Lol if you say so 😉

I had the roof rack fabricated out of aluminum localy by "exotic" welders haha.

But the rest of my drawings are all english.

What I meant was, is 400watts of solar worth all the trouble and money spent or will I barely get anything in return? I don't know maybe you should never go under 5-600watts for an efficient system? No idea...

DIY conversion build, extended 2010 Ford 5.4L E250 + high top, from Montreal Canada, new to all this so please be patient and clear with me (never built or camped in a van yet)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 06:16 AM

evy wrote:westend wrote:

One issue you're going to have with mounting any module on your roof is the carrier you have on there and shading. Even with nothing on the roof rack, if the modules are below the rack, a shade line will be crossing the cells and that shade line is going to be a thief of your harvest.

I'd suggest to do your audit and see how many amp hours/day you'll need. I'm thinking one large module will be enough to charge back fully in a morning.

If you look at my first post, and look at my roof rack, it is not your common "U" shape design that the side railings would be sticking up and casting shadows, it's basically an inverted "U"

The top platform has no sides.

And the flooring is made of a wire mesh that you can walk on so no shadows except maybe at sunrise/sunset if I have a kayak/canoe on the other side.

But yes I will do the audit.

As long as the modules are above the rack, no harm, no foul. If they are lower than the top of the rail of the rack, a shadow line will march across the modules with the transit of the Sun, ala a sundial. This will limit the harvest. If you camp in Ecuador, not much of a problem. If you are harvesting North of 45th parallel, you will see the effect, especially in Winter. Pull the truck into the sun and see if there are shadows. Raise modules accordingly.

I still believe there is good advantage to your initial installation plan, a module on the side with supports that elevate it. This leaves the roof rack to be used for it's purpose and no heroic measures to mount panels on the existing mesh. Tie wrapping acetate backed thin-flex modules sounds like a recipe for disaster. I think you'll also find that they do not produce power like a rigid module.

There are available panel racking systems or unistrut with attachment connections to various shapes. The racking systems have clips that allow modules to be attached easily. If you are contemplating full use of your roof rack, that is an another avenue to explore.

FWIW, when I was researching solar for my modest needs, it became evident that a single 24V (nominal) module and a small MPPT controller was going to give me good bang-for-the-buck, ease of installation, and give me good functionality from the controller. You can do your own cost analysis but be forewarned that with charge controllers, you get what you pay for. My controller was $200 but has temp compensation and full programmability for output and duration of cycles.

'71 Starcraft Wanderstar -- The Cowboy/Hilton

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 06:02 AM

So four x 100w panels is the maximum I can do.

That's settled.

DIY conversion build, extended 2010 Ford 5.4L E250 + high top, from Montreal Canada, new to all this so please be patient and clear with me (never built or camped in a van yet)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 05:47 AM

evy wrote:Almot wrote:evy wrote:

I'm afraid to ask what is better in series or parallel? lol

Shh... Don't ask. You are right to be afraid.

I'm not sure I understand what you mean about those flexible panels, they are 0.1" thick not 1.5"

I wrote "rigid panel". Must be 1am time in Montreal.

Yes it was very late lol

Know it's too early 😉

But I just want to understand, what's the problem with those semi flexible panels?

They sure would simplify things, using only tie-wraps to hold them into place so easy to move around, ultra light also, maybe they would vibrate or flap around with the wind on the highway? Unless I could manage to glue the center on the wire-mesh roof flooring? Is that the problem they have?

One word........"longevity".... internal shorting/open connections, cell cupping, (think of a bowl of water but with mud) scratching(while cleaning said mud) The risk of failure is to high for my blood....but perhaps not you?

Oh and zip tied to the mesh? Do you think flapping in the wind will increase there life cycle?....... Just some food for thought.

2016 Rockwood Mini Lite 2504S. TM2030 SC2030

640 Watts Solar. Costco CG2 208 AH and Lifepo4 3P4S 150 AH Hybrid. ElectroDacus. Renolagy DC to DC charger. 2000 Watt Inverter.

Boondocking is my Deal

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 05:16 AM

Almot wrote:evy wrote:

I'm afraid to ask what is better in series or parallel? lol

Shh... Don't ask. You are right to be afraid.

I'm not sure I understand what you mean about those flexible panels, they are 0.1" thick not 1.5"

I wrote "rigid panel". Must be 1am time in Montreal.

Yes it was very late lol

Know it's too early 😉

But I just want to understand, what's the problem with those semi flexible panels?

They sure would simplify things, using only tie-wraps to hold them into place so easy to move around, ultra light also, maybe they would vibrate or flap around with the wind on the highway? Unless I could manage to glue the center on the wire-mesh roof flooring? Is that the problem they have?

DIY conversion build, extended 2010 Ford 5.4L E250 + high top, from Montreal Canada, new to all this so please be patient and clear with me (never built or camped in a van yet)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-23-2016 04:51 AM

westend wrote:

One issue you're going to have with mounting any module on your roof is the carrier you have on there and shading. Even with nothing on the roof rack, if the modules are below the rack, a shade line will be crossing the cells and that shade line is going to be a thief of your harvest.

I'd suggest to do your audit and see how many amp hours/day you'll need. I'm thinking one large module will be enough to charge back fully in a morning.

If you look at my first post, and look at my roof rack, it is not your common "U" shape design that the side railings would be sticking up and casting shadows, it's basically an inverted "U"

The top platform has no sides.

And the flooring is made of a wire mesh that you can walk on so no shadows except maybe at sunrise/sunset if I have a kayak/canoe on the other side.

But yes I will do the audit.

DIY conversion build, extended 2010 Ford 5.4L E250 + high top, from Montreal Canada, new to all this so please be patient and clear with me (never built or camped in a van yet)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-22-2016 11:29 PM

I'd suggest to do your audit and see how many amp hours/day you'll need. I'm thinking one large module will be enough to charge back fully in a morning.

'71 Starcraft Wanderstar -- The Cowboy/Hilton

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-22-2016 10:07 PM

evy wrote:

I'm afraid to ask what is better in series or parallel? lol

Shh... Don't ask. You are right to be afraid.

I'm not sure I understand what you mean about those flexible panels, they are 0.1" thick not 1.5"

I wrote "rigid panel". Must be 1am time in Montreal.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-22-2016 10:01 PM

Almot wrote:Naio wrote:

Will I gave to forego this, with solar,

Yes. You don't want car-washers messing around panels on the roof, no matter what panels. Washing under the raised rigid panels is "possible" though tends to be done less frequent than before you installed them 🙂

Oh, that is a lot to give up!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-22-2016 09:59 PM

Almot wrote:

You don't have to decide on controller right now unless you have a strict budget. There WILL BE a controller for 400-600W that you are planning.Can I put 4 x 100w instead of these massive 66"x39" 285w panels? I know I'm loosing 85w and it'll be more expensive but I really don't know where I would fit another one of these.

I meant one 285W on the side like you said, and "another" one on the rear part of the roof.

4*100 you can do either all parallel, or in pairs, or all-series.

5*100 you would have to wire all-series.

I would stay away from those flexible sheets. Solar Blvd had some square-shaped 80W rigid panels. When raised 3" above the roof (1.5" panel thickness, 1.5" from frame to roof), rigid panel won't disturb the balance or air turbulence on the road.

I'm afraid to ask what is better in series or parallel? lol

I'm not sure I understand what you mean about those flexible panels, they are 0.1" thick not 1.5"

Can you just rephrase, I don't speak english to often sometimes I just don't get it lol

http://www.amazon.com/dp/B01DXYNGA0?psc=1

DIY conversion build, extended 2010 Ford 5.4L E250 + high top, from Montreal Canada, new to all this so please be patient and clear with me (never built or camped in a van yet)

- electrical in Technical Issues

- RV shore power plugged into inverter run by 12v battery and 100w solar panels in DIY Maintenance

- Norcold NN611VRT issue running of electric in Technical Issues

- Running A/C over draws the batteries causing inverter alarm in Technical Issues

- Solar advice requested. in Technical Issues