- Good Sam Community

- Groups

- Truck Camper Group

- Forum

- Happijac lubrication

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Happijac lubrication

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-17-2009 07:37 PM

First you have to make a little tool like this. An old hanger works good. This will serve two purposes, explanations following.

Remove the two screws that hold on the motor.

Pull the motor off the jack.

Pull out the spring loaded socket.

Remove the lever and pin...a pair of flush wire cutters works well. Wedge them underneath and they pop right out.

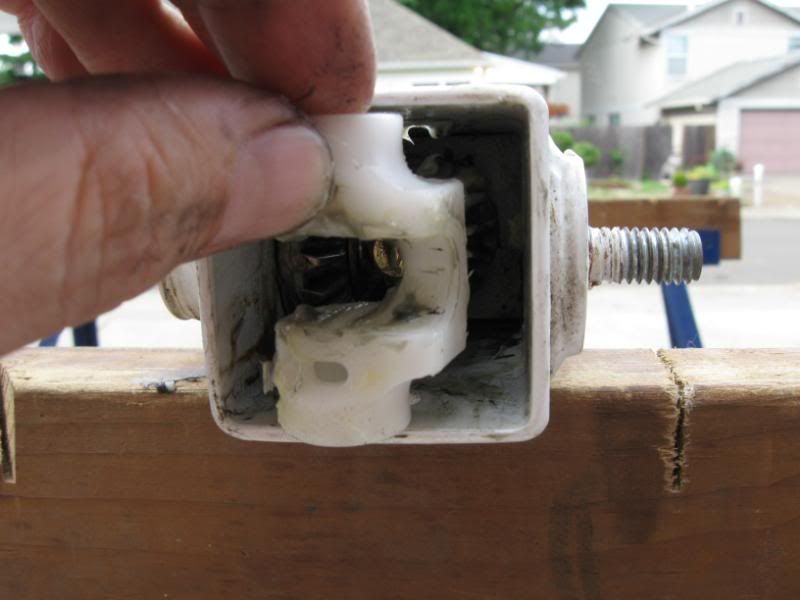

Remove the internal plastic manual mechanism...note how this is installed. one side has a round hole and the other an oval shape where the lever goes.

There is a "C" clip here, you need to remove it with the little tool you made. Just put it in from the side and pull back. It will pop right out.

Once you get the clip off then pull out the manual socket.

This is the hole in the socket that is to be oiled, but as you can see in the next few pics, the only thing that is being lubed is the socket itself.

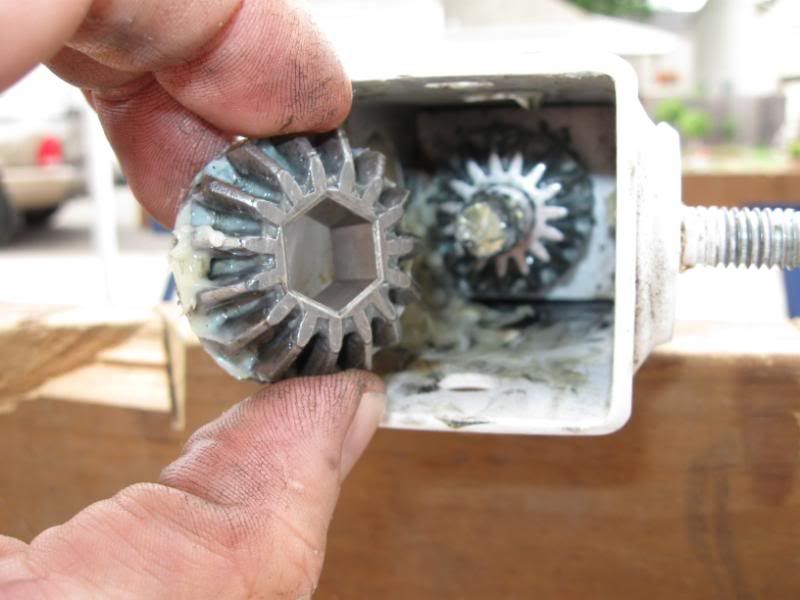

Once you pull out the socket, remove the manual gear.

Now as you can see the oil really goes nowhere. There is actually a lot of grease here. What your going to do next is pull this gear off that shaft straight towards you. Use that tool again to hook the gear from behind and pull it. You may have to do it a few times, the shaft gets a little burr on it but if it gets stuck ,just push it down and keep yanking, it will come off!

Once the gear comes off, this is what the back looks like. It has two slots. The slot that has the closed ends is what holds the pin in place. IT IS IMPORTANT YOU PUT THIS BACK TOGETHER THE WAY IT COMES APART!

Rotate the shaft so the pin is facing towards the corner and pull it out.

Now pull the leg assembly out of the jack housing.

Get ready to inspect and re lube.

Pull this cinch spring off and inspect this bearing.

Use an air ratchet or drill to turn the worm screw all the way out, inspect and re lube.

Re-assembly is just the opposite of the tear down. I found that even though this jack was sticking on me, it was still pretty well lubed, but maybe not enough.....Hope this dispels any unknown facts as to how these things work. One other note is that if the worm drive of the leg was to wear out...seems like you should be able to replace it rather than the whole jack. MMMMMM...haven't got to that yet but I wonder if they sell it seperatly? Does any one know?

- Labels:

-

Truck Campers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-24-2017 05:04 PM

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-24-2017 03:38 PM

Once I got the gear off I thought I was home free to complete the chore...

But... the bottom leg would not extract from the housing! I think there was so much rust inside and it wedged between the inside of the outer shaft and outside of the inner shaft. There were deep scores in the paint of the inner shaft clear to the steel:

I tried tapping the lower leg out with a hammer to no success. Then I got a bigger persuader but it started to really tear up the foot pad:

I figured if I could at least get the jack apart I can weld up a new pad so I keep on pounding. But in all of the banging I only budged the lower leg about 9"... whatever is bound up inside will no longer allow it to move. At one pint I had already resigned myself that I will be buying a pair but I wanted to get this dang thing apart to see the inerds.

Who has the best prices on jacks?

2005 Dodge 3500 SRW, Qcab long bed, NV-6500, diesel, 4WD, Helwig, 9000XL,

Nitto 285/70/17 Terra Grapplers, Honda eu3000Is, custom overload spring perch spacers.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-23-2017 02:34 PM

d3500ram wrote:

Was/ is there a consensus on the best type of grease to use for this repair?

I used boat trailer axle grease...

That was over 10 years ago... No more issues as of yet. I do use our jacks a lot!

Jim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-23-2017 02:22 PM

2005 Dodge 3500 SRW, Qcab long bed, NV-6500, diesel, 4WD, Helwig, 9000XL,

Nitto 285/70/17 Terra Grapplers, Honda eu3000Is, custom overload spring perch spacers.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-23-2017 06:43 AM

jjinatx wrote:

My 1st truck camper had manual jacks. I got a socket for my cordless drill that fit like the crank. Mush easier than hand cranking.

-jj

My RT's are manual as well. The TC is set up for electric jacks but the heads are expensive (1500 bucks) and I can buy a lot of cordless drills for 1500. Mine are the same, up and down with a drill adapter. I run 2 cordless drills. my wife has one, I have the other, she is on one side, I'm on the other. Takes us about 5 minutes total from storage position (jacks retracted) to extended.

Maybe 'Santa' will send a set down the chimney this Christmas, who knows.

I'm being a 'good' boy this year... I think at least.:R

1997 Ford 7.3 OBS 4x4 CC LB

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-23-2017 05:44 AM

-jj

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-22-2017 04:19 PM

2005 Dodge 3500 SRW, Qcab long bed, NV-6500, diesel, 4WD, Helwig, 9000XL,

Nitto 285/70/17 Terra Grapplers, Honda eu3000Is, custom overload spring perch spacers.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-22-2017 04:05 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-22-2017 01:03 PM

It does not have a motor... fully manual 4150's on all 4 corners of a Northstar Arrow camper as indicated in signature 2 posts above. I am going to tackle it this weekend.

Also- If anyone wants a document copy of the procedure, PM me with an e-address and I can forward a .docx. doc and PDF version for any member who would like one.

2005 Dodge 3500 SRW, Qcab long bed, NV-6500, diesel, 4WD, Helwig, 9000XL,

Nitto 285/70/17 Terra Grapplers, Honda eu3000Is, custom overload spring perch spacers.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-21-2017 11:51 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-21-2017 07:34 PM

1) I have manual 4150 jacks with no motor. Can I assume that the procedures described within will for the most part apply to manual jacks?

2) Before any disassembly, does the jack need to be in a fully retracted (up) position? My jack in question is really kinda' tight in the position it is in that I do not think I can retract it if that is necessary. Can I disassemble in the current partially extruded position?

thanks.

2005 Dodge 3500 SRW, Qcab long bed, NV-6500, diesel, 4WD, Helwig, 9000XL,

Nitto 285/70/17 Terra Grapplers, Honda eu3000Is, custom overload spring perch spacers.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-09-2017 03:43 PM

Old Islander wrote:

BTW, HappiJac sent me a package of 13 PDF's with a good deal of information about these jacks (exploded diagrams, etc). They total about 10 megs. If anyone can suggest a public place to upload them so they're available to all, I'd be happy to do that.

I use http://files.engineering.com/upload.aspx. Not sure what the size limit is.

'17 F350 Powerstroke Supercab SRW LB 4X4

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-09-2017 12:07 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:59 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:29 PM

One issue I had with mine was the socket part that the manual jack handle inserts into.

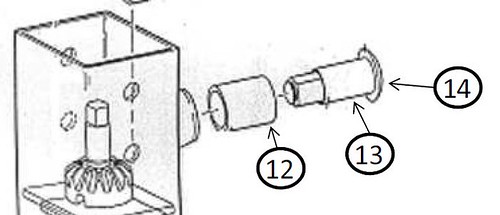

Here they are from the exploded parts diagram:

On a couple of my jacks, this metal insert (#13) was so stiff turning in the plastic sleeve (or bushing), that the housing got quite hot while running the jacks up/down. The electric motors were working a lot harder than they should have had to. A bit of machine oil in the socket didn't help.

I have a wood lathe and after cleaning the surface of the metal insert, mounted it on the lathe. Then trued it up with a fine flat metal file. It was almost like some sand had gotten in there and scored the surface. When I reinserted it into the plastic bushing with some lithium grease, it turned as smooth as butter, and the jack now works perfectly.