- Good Sam Community

- Everything RV

- RV Tips & Tricks

- Good and Bad about Blue Ox Sway Pro

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Good and Bad about Blue Ox Sway Pro

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-22-2013 05:07 PM

Thanks in advance for taking a moment to tell me the good and bad!!

Lovely Wife Carla 🙂

The Crew Alicia and Johnathan :B

The Camping Dog Kamp Chaos 🙂

2013 Keystone Cougar 32RBK

2006 Ford F350 Crew Cab Lariat 6.0 PowerStroke

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-15-2013 05:17 PM

CHD Dad wrote:

Following up on this - I have not received a response to two emails back to them. Site claims email reply within 3 hours which was the case when I got the canned response the first time. When I got more specific they have ignored me so far. I then placed two phone calls, 3 days apart (Mon and Wed). Both times the rep could not answer any of the specific questions that were brought up earlier. Both times the rep told me an engineer would be happy to call me back to explain how their sway control works vs. any other manufacturer with head tilt, angles of deflection needed between TV/TT, etc.

Still waiting on that call...

They were very responsive with me and friendly. Perhaps you questioned their design and they had no other answer to say except that they feel it controls better than other systems.

I was just disappointed as I thought there was more to the bar angles.

The way the engineer explained it to me in the email, I thought it had the standard down tilt, but also twisted outward with offset so that the bars would swing up and down at greater angles when out of a straight line alignement. I actually pictured the bar catch trunnion with the pin not being straight up and down, but twisted a bit sideways, at a predetermined angle. I just misunderstood and see that they simply made that predetermined angle on just the downward tilt, that almost all trunnion bar systems offer.

The bad thing about the Blue Ox Sway Pro, is that if the built in sway control turns out to minimal and poor, there's no way of adding additional friction sway control arms, like on a basic (no Dual Cam) Reese trunnion or round bar chain pull up WDH.

BTW, the engineer did personally call me and I talked with him. However it's obvious that his explanation didn't clearly detail the sway control action as I came away with the same thought as I did with the email.

Live and learn.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-15-2013 05:11 PM

So I was researching the Equalizer brand. It seems a good alternative to the Reese Dual Cam HP system since they corrected the sliding arm bracket. I then found in the instructions that you couldn't use a traditional ball nut wrench. You had to use a 1 7/8" socket since the nut went into an enclosed area. The sockets are about $25 but they are 3/4" drive which is very very expensive. Since this size drive is in the hundreds, I thought about just using a 3/4" drive breaker bar. Luckily Sears had one where the head slides up and down on a round bar. It was $33. So just to put the ball on would cost $58 and that's with no torque spec!!!

Before I even planned to buy another hitch system, Blue Ox or Equalizer, I wanted to take apart my Reese Dual Cam system. I previously broke the head socket by the bar pushing against the cam lobe from an incorrect install. Then I found another problem after dealer sent tech to my home, to replace broke parts and reinstall. I found one of the cams was angled up, not allowing the bar indent to seat flat on the cam and get wedged into the gap between the cam and the cam pull up bracket. So I took it all apart to inspect. I thought I found a bent cam frame bracket.

Well took it all apart and neither of the cam frame brackets are welded perfectly square but I thought the one tab that bolted to the frame had bent.

I swapped the cams and now everything fit perfect.:h

Well I then put the cams back into their original frame brackets and now everything is square and perfectly aligned.:h

Thought maybe it was aligned because the force wasn't on the cam to push it out of alignment. Well, hooked it all up and pulled it about 50'. ALL IS GOOD!:B

The service tech somehow bolted it out of alignment but it's all good now. Very Strange but I'll take it.

I readjusted the cam on the bar indents and all is perfect now.

I may need to adjust the links, not sure. Even though my new 2012 F150 is supposedly the same truck as my 2010, the ride is a bit stiffer. Better suspension?? Or is it the lower profile 18" tires next to the 2010's 17" tire's tall side wall profile?? I'll see and if it needs, I'll adjust it on the go. Actually this parts pretty easy.

So I'm sticking with my Reese since it's working. Keeping my fingers crossed.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-15-2013 09:52 AM

Still waiting on that call...

2015 Nissan NVP 3500 SL 5.6L

Tekonsha P3 / "New" Blue Ox Sway Pro

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-12-2013 11:21 AM

(cam follower)

Also, it is the whole system, not just the WD Hitch system.

First thing I've always done when asked to help. Is to check tongue weight

and levelness

How much force does a trunnion/round-bar with a 'hook' at the end where there

is a cam going to produce when it goes off center?

1996 GMC SLT Suburban 3/4 ton K3500/7.4L/4:1/+150Kmiles orig owner...

1980 Chevy Silverado C10/long bed/"BUILT" 5.7L/3:73/1 ton helper springs/+329Kmiles, bought it from dad...

1998 Mazda B2500 (1/2 ton) pickup, 2nd owner...

Praise Dyno Brake equiped and all have "nose bleed" braking!

Previous trucks/offroaders: 40's Jeep restored in mid 60's / 69 DuneBuggy (approx +1K lb: VW pan/200hpCorvair: eng, cam, dual carb'w velocity stacks'n 18" runners, 4spd transaxle) made myself from ground up / 1970 Toyota FJ40 / 1973 K5 Blazer (2dr Tahoe, 1 ton axles front/rear, +255K miles when sold it)...

Sold the boat (looking for another): Trophy with twin 150's...

51 cylinders in household, what's yours?...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-11-2013 09:09 PM

2014 ORV really big trailer

2015 Ford Focus ST

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-11-2013 07:28 PM

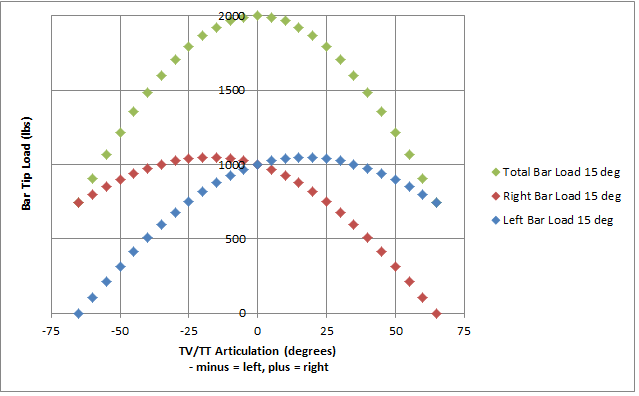

BenK wrote:The following chart shows how bar-tip force varies as a function of TV/TT articulation.

The amount of forces +/- is factored by the number of chain links, or more accurately how much the chain will allow the bar end to move or not move. The bar's preload will either increase or reduce...but am having problems with that, so see last sentence

I'll let you guys hypothesize the pound forces, both push and pull on

the tongue in reference to the center line

The chart assumes each trunnion axis is offset 4" from the ball center and the A-frame included angle is 50 degrees.

Each trunnion axis is tilted at 15 degrees in a vertical plane which is parallel to the TV's longitudinal centerline.

Each bar is loaded to 1000# at zero articulation (TV and TT aligned straight ahead).

Next we need to consider how much the right bar tip moves "forward" relative to its chain suspension point and how much the left tip mores "rearward" when the TT swings left.

Assuming a 4" offset for each bar trunnion, 25-degree angle between A-frame and TT centerline, and 30" from ball center to chain suspension point --

if the TT swings 5 degrees left, the right bar tip will move forward a theoretical 0.337" and the left will move rearward 0.327".

If we assume the distance between bar tip and chain suspension point is 4" (about what it looks like in the Blue Ox videos),

each chain will be at an angle of about 5 degrees from its original assumed vertical orientation.

The load on the right bar has increased to 1025# and it will be pulling forward with a force of 86# on the right chain latch.

The load on the left bar has decreased to 968# and it will be pulling rearward with a force of 79# on the left chain latch.

So, the forces due to the inclined lift chains will tend to return the TT to zero articulation.

HOWEVER, if the WD bar trunnions were at zero tilt and assuming the same distance from bar tip to chain suspension point, the restoring force would be almost identical to (actually slightly greater than) the restoring force resulting from the tilted trunnions.

And, the difference in favor of the non-tilted trunnions will increase as the articulation increases.

So, if there is truth in the assertion that tilted trunnions will provide a measure of sway control which cannot be provided by zero-tilt trunnions, I think we have not yet found the reason.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-11-2013 04:21 PM

each bar. Their offsets are the distance from the ball's center line

The bar attachment to the tongue is fixed and there is compliance via

the chains. The center of that attachment is vague and needs noodling

but suffice to say it is within the chain latch assembly.

As the trailer goes off center line both bars will follow via their

attachment chain and rotation on 'their' center line

Since different center lines, those points (the attachment points on

the tongue and the bar chain attachment points) all three will swing

in an arc. The trailer moves towards the drivers side for this discussion

The passenger side will have the distance from the tongue attachment

point to bar axis of rotation increase

If the bar was fastened solidly on the tongue...it would NOT allow the

tongue to swing to the drivers side, but since attachment is via a chain,

the tongue is allowed to swing towards the drivers side

The other (drivers) side bar will reverse mirror that, as the

distance between the tongue fixation point to bar axis of rotation

will REDUCE

One bar is in tension and the other will be in compression...but they

are NOT straight, but bent

The amount of forces +/- is factored by the number of chain links,

or more accurately how much the chain will allow the bar end to move

or not move. The bar's preload will either increase or reduce...but

am having problems with that, so see last sentence

I'll let you guys hypothesize the pound forces, both push and pull on

the tongue in reference to the center line

This is part of how a WD Hitch System (traditional, non-Andersen)

sway controls. The change in bar loading is another...I think and back

to the last sentence. 'Think' in changing the WD'ing on the TV has

some effect, but not sure enough to post and get rocks tossed at me, again...

The part am having a tough time visualizing is the heat tilt and what

that does dynamically to the above {edit}...have understood how the

head tilt works for increasing the bar tension, but +/- distance and

resistance to off center tongue movements is only a few years old in

my old noggin... :B

1996 GMC SLT Suburban 3/4 ton K3500/7.4L/4:1/+150Kmiles orig owner...

1980 Chevy Silverado C10/long bed/"BUILT" 5.7L/3:73/1 ton helper springs/+329Kmiles, bought it from dad...

1998 Mazda B2500 (1/2 ton) pickup, 2nd owner...

Praise Dyno Brake equiped and all have "nose bleed" braking!

Previous trucks/offroaders: 40's Jeep restored in mid 60's / 69 DuneBuggy (approx +1K lb: VW pan/200hpCorvair: eng, cam, dual carb'w velocity stacks'n 18" runners, 4spd transaxle) made myself from ground up / 1970 Toyota FJ40 / 1973 K5 Blazer (2dr Tahoe, 1 ton axles front/rear, +255K miles when sold it)...

Sold the boat (looking for another): Trophy with twin 150's...

51 cylinders in household, what's yours?...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-11-2013 07:02 AM

Barney

Hensley "Arrow" 1400# hitch (Sold)

Not towing now.

Former tow vehicles were 2016 Ram 2500 CTD, 2002 Ford F250, 7.3 PSD, 1997 Ram 2500 5.9 gas engine

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-11-2013 06:48 AM

2015 Nissan NVP 3500 SL 5.6L

Tekonsha P3 / "New" Blue Ox Sway Pro

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-10-2013 09:59 PM

CHD Dad wrote:

If I follow your video, when the TT is not in a straight line the added tension on one side will help pull it back into line. Wouldn’t all designs do that? Second, how far out of line does the TT need to get on a typical 1000# hitch setup which seems the most common. Would the TT need to get several degrees or feet off center for physics to kick in on the bars to pull things straight? I thought I read that you got rid of the torque bolts to prevent “dog tracking” but other friction systems don’t seem to have that issue unless they are way too tight or on something like a snowy road.

Blue Ox Representative wrote:I consider this to be a very disappointing response to your specific questions.

Thank you for your interest in the Swaypro, we built caster into the trunions of the hitch head. This is what gives you the sway prevention and the friction sway control is not needed, it does not need to go off center for it to work, it is always working. This is similar to caster in a car, when going down the road the caster built into your front end keeps you straight going down the road and returns you to center when turning a corner. Blue Ox Swaypro is unique in the built in caster. I hope this answers your questions below. Please let me know if you have further questions.

You asked, "Wouldn't all designs do that?" The response was, "we built caster into the trunions of the hitch head."

The only thing different about their hitch is the trunnion angle is not adjustable.

Other hitches can be set at similar tilt angles.

Does that mean they also have built-in caster and don't need any other sway-control mechanism?

The only parallel I can see with automobile front-suspension caster is that the automotive kingpin pivots on a axis which is "tilted" rearward at the top,

and the WD bar trunnion pivots on an axis which also is tilted rearward at the top.

But, the similarity ends there.

To have a "caster" effect, a wheel needs to be attached to the lower end of a kingpin so that the wheel's contact point with the pavement is behind the point at which the kingpin's axis intersects the pavement.

And, whatever effect the Blue Ox tilted trunnion has, it is not unique.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-10-2013 06:52 PM

I also emailed them and received a quick reply. See below.

Thank you for your interest in the Swaypro, we built caster into the trunions of the hitch head. This is what gives you the sway prevention and the friction sway control is not needed, it does not need to go off center for it to work, it is always working. This is similar to caster in a car, when going down the road the caster built into your front end keeps you straight going down the road and returns you to center when turning a corner. Blue Ox Swaypro is unique in the built in caster. I hope this answers your questions below. Please let me know if you have further questions.

Thank you

Deanna

Blue Ox

Subject: SwayPro question

Hello – I am very interested in your Swaypro hitch. My friend has the old design and loves it. Never had a single issue and has towed thousands of miles with his rig. The new design is intriguing but I fail to see how it controls sway with zero friction. The old system had the bolts on the bottom to torque down similar to the Equal-i-zer. The new system swings freely from side to side (I got to look at one in person). I watched your computer simulation and understand what is being said, but how is your new design any different than any other hitch if you max out the head tilt of it? Reese, EQ, Curt, etc. – just max out the head tilt and their geometry would be similar. They all still have and need some sort of friction to control sway, be it an add on sway bar or built into the head/contact point or in the cam lobes. Your tilt is extreme but it doesn’t look to be so much more extreme than what could be done on most other hitches. Your chain capturing is unique and I like that quite a bit.

If I follow your video, when the TT is not in a straight line the added tension on one side will help pull it back into line. Wouldn’t all designs do that? Second, how far out of line does the TT need to get on a typical 1000# hitch setup which seems the most common. Would the TT need to get several degrees or feet off center for physics to kick in on the bars to pull things straight? I thought I read that you got rid of the torque bolts to prevent “dog tracking” but other friction systems don’t seem to have that issue unless they are way too tight or on something like a snowy road.

I am sincerely interested in purchasing the hitch. There are many pluses about it that I like but sway control is very important to me.

2015 Nissan NVP 3500 SL 5.6L

Tekonsha P3 / "New" Blue Ox Sway Pro

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-10-2013 02:16 PM

CHD Dad wrote:I'd say you have a better understanding of the load-deflection characteristics of a cantilever beam than some engineers do.

Definitely not an engineer so please feel free to laugh at my comments...

I thought the whole point of any tapered bar such as what is on the Blue Ox is that tip will flex more than the base.---When a force is applied to the free end of a cantilever beam, a bending moment will be imposed on the beam.

The bending moment will be zero at the tip and will vary linearly along the beam to a maximum moment, at the fixed end, equal to force times length.

The curvature at any point along the beam is directly proportional to the bending moment.

Curvature also is inversely proportional to the beam's area moment of inertia which, for a rectangular cross section, is equal to thickness cubed times width divided by 12.

For a beam of constant cross section, the curvature at any point will be maximum at the fixed end and will vary linearly to zero at the free end. The deflected shape, in this case, would be a parabola.

For a tapered beam, either tapered in width or tapered in thickness, the curvature along the beam might be constant. In this case, the deflected shape would be a circular arc.

If a tapered beam and a non-tapered beam have the same cross section at the fixed end and are subjected to the same force at the free end, the free end of the tapered beam will deflect more.

The tapered beam also will be subjected to greater bending stress along the length of the beam.

In fact, with the correct amount of taper, a tapered beam could be designed to have constant bending stress along its entire length.

If its the same cross section, but the material is thinner it should flex easier and faster than the thicker material towards the end of the bar going into the socket. It should be "progressively" easier to flex the bar the farther away you move from the socket as the bar tapers down in thickness.Yes, as distance from the fixed end increases, the curvature of the tapered beam will be greater and the deflection will be greater than for the non-tapered.

However, the amount of tip deflection for any given beam, remains directly proportional to the applied load.

When the term, "progressive", is applied to a spring it usually means that the "spring rate" (incremental load divided by incremental deflection) increases as the deflection increases. This is not the case for a tapered beam.

While the amount of force exerted to the hitch head is constant, isnt the bar designed to be progressively softer the further away from the head? My thoughts are that is progressive in nature. The tips can flex easier to help absorb any shocks or small movements and as the load against them ramps up during a turn they resist flexing the further out of line it gets.The force acting on the tip of a WD bar with a tilted trunion is close to its maximum when the TV and TT are aligned.

As a turn is made, there is a slight increase in force followed by a relatively rapid decrease.

If not, what is the point of tapering the bar? Weight savings? You could make the entire bar smaller in cross section. It would be much cheaper than having those bars made with the taper to just saw cut mults out of plain bar stock.As mentioned earlier, with a tapered bar, you can achieve a more uniform distribution of bending stress along the length of the bar.

This means you can support a greater tip force with less material.

The bar is lighter, but can support the same load as a non-tapered bar.

In the case of the new Sway Pro, one possible advantage for the tapered bar is greater tip deflection for a given load.

Other WDHs have chains or L-brackets which can be used in combination with ball mount tilt for "fine tuning" the adjustment of the WD bars.

The new Sway Pro only has the rotating latch for "fine tuning".

The tuning resolution provided by a combination of chain links and head tilt probably is finer that that provided by chain links only.

Since the tapered Blue Ox bar has a lower "spring coefficient", a change of one chain link would give a finer tuning than using only the chains on other WDHs.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-10-2013 12:51 PM

Mike Up wrote:IMO, the new Sway Pro will not come close to providing as much "sway control" as the EQ or DC do.

So Ron, am I reading correctly as you don't feel the Blue Ox is going to do much sway control or prevention as an Equalize brand hitch or Reese Dual Cam hitch will do?

I would not tow with the new Sway Pro without using one or two friction sway bars.

I am a fan of other Blue Ox towing products and would like to be able to change my opinion regarding the "sway control" ability of the new hitch -- so, I'll continue to look for reasons to do so.

So far, I've not read, or been able to come up with, any convincing arguements.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-10-2013 10:11 AM

I thought the whole point of any tapered bar such as what is on the Blue Ox is that tip will flex more than the base. If its the same cross section, but the material is thinner it should flex easier and faster than the thicker material towards the end of the bar going into the socket. It should be "progressively" easier to flex the bar the farther away you move from the socket as the bar tapers down in thickness.

While the amount of force exerted to the hitch head is constant, isnt the bar designed to be progressively softer the further away from the head? My thoughts are that is progressive in nature. The tips can flex easier to help absorb any shocks or small movements and as the load against them ramps up during a turn they resist flexing the further out of line it gets.

If not, what is the point of tapering the bar? Weight savings? You could make the entire bar smaller in cross section. It would be much cheaper than having those bars made with the taper to just saw cut mults out of plain bar stock. Maybe bar travel? If the whole bar was thin maybe it would flex too much. Make it too thick and it would transfer every small shock load into the TT/TV combo and hitch head.

I will be the first to admit I was pretty upset with Blue Ox when they changed the design. My concerns at the time were that they didnt tell anybody about it and even Blue Ox customer service wasnt ready to answer the how and why questions. I ended up frustrated with it all and sent it back. Now that its been explained by users and Blue Ox the system again looks intriguing enough to try.

2015 Nissan NVP 3500 SL 5.6L

Tekonsha P3 / "New" Blue Ox Sway Pro

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-10-2013 10:01 AM

- Ram truck ABS/HCU recall in Tow Vehicles

- Norcold N821 inconstant cooling in Technical Issues

- VIDEO: F-250 Enlarging Cold Air Intake Using Existing Parts Cheap And Easy 2000 F250 5.4 Liter in Tow Vehicles

- Blue ox in RV Tips & Tricks

- Atwood hydro flame model 2H2C Two stage Furnace Digital Thermostat in Technical Issues