- Good Sam Community

- Everything RV

- Technical Issues

- Re: 3000W Chinese Gensets Info.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

3000W Chinese Gensets Info.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-02-2005 06:20 AM

professor95 wrote:

EDIT ADDED 45/5/2013- When this thread started in March of 2005, I never expected to see it survive this long or amass the quantity of information that has been shared here.

In the eight year run of this thread we have amassed almost 10,000 postings and surpassed a million views. This creates somewhat of a dilemma for anyone who has just discovered the forum.

Since the amount of information is virtually overwhelming, I suggest you set your preferences for this thread to read "newest first" and then begin to page backwards.

What you will find in these pages is a wealth of info on virtually any make or model of Chinese manufactured synchronous (non-inverter) generator in the 3,000 watt performance class. Info will include how to rewire series coils to parallel to obtain maximum wattage from a single 120 volt outlet. Tips on further reducing sound levels, how to care for these generators, which ones are "RV ready" and provide the best overall performance for the dollar invested. Which companies NOT to deal with, where the best prices are, how to safely wire the generator into a home or RV, how to check your RV for electrical faults, sources for generator accessories, which 20/30 adapters are safe to use and which are not. How to convert a gasoline generator to propane or NG. This is only the beginning. The forum has a life of its own with the focus sub-topic switching frequently. Still, the main topic of utilizing the amazing, inexpensive Chinese gensets is always there. The amount of creativity and innovation presented in these pages is indicative of the talents shared in the diverse backgrounds of the folks who make up our combined RV community.

Many of the original brands and models of Chinese gensets mentioned in the introduction and early pages of the thread have since disappeared. New EPA and CARB emissions requirements, company bonds assuring the emissions warranty will be honored even if the company goes out of business, and fierce competition in the industry have changed the playing field. Champion Power Equipment has become the apparent "trophy team" providing an ever expanding retail outlet, an ample parts supply, a strong warranty and excellent customer service. CPE has continued to improve their product and now offers a new model (#46538) with exclusive convenience, safety and performance features aimed at the RV market. Big names like Cummins/Onan, Honda and Generac all now have Chinese built open frame synchronous gensets available. Ironically, the prices often found on these gensets has not significantly changed during the past eight years - even with the devaluation of the American Dollar and new EPA/CARB requirements.

I also encourage you to use the search function and even the advanced search options to find information. Key works such as "rewiring", "PowerPro", "Champion", "Onan Homesite", "Duropower", "ETQ", "Jiung Dong or JD", "Tractor Supply", "Costco", "Lowe's" and "Home Depot" are all examples of keywords that will give you specific information on different models being sold by retailers today.

Or, you can fill your glass with your favorite beverage (keep more close by - maybe some munchies as well :D, sit back at your computer, tell your wife (or significant other) that you will see her in the morning and spend the next 10 or so hours reading through the postings.

No one on the forum gets mad if you ask a question that is a repeat. Please do not hesitate to post to the forum. All questions are considered important and those active on the forum will do their best to respond with a valid answer.

Also note we are not out to knock the Honda, Yamaha, Kipor or other brands of high end digital gensets. We recognize the quality of these products and their suitability for quite, efficient RV use. But, there is a flood of reliable, inexpensive and comparatively lower cost gensets coming out of China that are excellent alternative choices for the RVer wanting power to run an air conditioner, microwave, etc. without excessive noise or breaking the budget.

Oh, one last thing. The folks on this forum are true gentlemen. We do not flame one another or the product discussed - period. Ugly contributors usually have their comments and remarks ignored by our masses. It is not a forum to start arguments to obtain a clear win. We do disagree on many issues, but we have all agreed to do that in a respectable manner.

We now have the introduction of more and more inverter gensets. There is a rather extensive thread named "The Official Unofficial Champion 2000i Generator" on this forum. Today, I added info on the new Champion 3100i inverter genset. Discussion on this product may get moved to its own thread at a later date.

Many have looked upon this thread with distain saying Chinese is cheap and doomed to failure. I remember saying exactly the same thing about Japanese products a few decades back. But, over the past eight years the track record for Chinese built generators has shown otherwise.

Please, join us in a fascinating journey down the Chinese built genset road of knowledge.

This is the question I posted that got it all started back in March 2005.......

Randy

For a little over a month now, I have been somewhat intrigued by the availability of a 3000 watt, 6.5 HP generator at Pep Boys and Northern Tool for under $300.00. The engine on this generator looks identical to a Honda 6.5 HP OHV engine. Knowing that the Chinese have become very adept at “cloning” reputable technologies from other manufacturers, I was not surprised at the similarities. Neither store could give me any information on the generator nor did they have a “running” display model.

I have done a little research. This is what I have discovered:

Many of these generators are imported by ELIM International (www.eliminternational.com) out of Buffalo, New York from Jiung Manufacturing in China. (The unit at Northern is identical but carries the JIUNG name.)

The engines are indeed a Chinese knockoff of the popular 6.5 HP 196cc Honda Engine. “Supposedly” Honda has licensed the engine technology to the Chinese manufacturer of the product.

The Chinese company that makes the ELM3000 generators is a rather large, diverse, long-standing company with a reputation for “above average quality” Chinese made products (Jiung Manufacturing). There are many more Chinese companies making almost identical gensets.

The generators at PepBoys do have a six month limited warranty. But, it is only on the engine (not the generator) and requires paying for shipping to and from Buffalo. Probably not a very practical thing to do if you have warranty issues.

ELIM does supply replacement parts (a PDF parts manual is available on the ELIM web site). No prices are given for replacement parts nor is there an “availability listing”.

The generator head itself is a brushless design. The only really significant wear parts in the generator are the bearings – most likely universally available.

The published dB rating is 67 at 23 feet. This is “reasonably” quite for a generator of this size as most comparabl.... The 67 dB rating is the same as Honda gives their 3000 watt CycloInverter with a “look alike” eng...

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-08-2010 11:01 AM

I elected the down draft fan on the current install mostly because it was my only logical choice. But, on the previous install inside the insulated box the lower center exhaust fan was elected because it was the closest to the normal exit path for both cooling air across the engine and through the alternator.

I did not do any flow testing on updraft fans, but I do know that they work. It just did not seem practical to be bringing heated air back across components I was trying to cool.

The biggest mistake I see is NOT considering air flow in the cabinet design. There is (was?) a mistaken theory that hot air came out the back of the alternator. The actual path is into the back of the alternator and out the bottom where the alternator connects to the engine.

Incoming air flow to the engine fan/shroud and rear of the alternator is critical. Absolutely nothing should be there to keep cool air from flowing in or to allow recirculation of heated air from inside the cabinet. Simply putting a big fan on a box will not work!

As for a 12 VDC source, why are you even using yet another battery? I elected to use the on-board camper battery for starting and running the 12 volt fan. Why add weight and maintenance that is un-needed? Additionally, the battery charger output from the generator is unregulated. It “might” recharge a battery in a pinch, but the life span of the battery will be proportionally reduced in relation to the frequency of using the generator battery charger. 10 gauge copper wires are good for running to the starter for a distance of 20 feet. You can go longer but the voltage drop at the 25 amp cranking current begins to become a consideration. Best to parallel twin #10 or even #12 wires after 20 feet unless you want to run larger gauge #8 or #6.

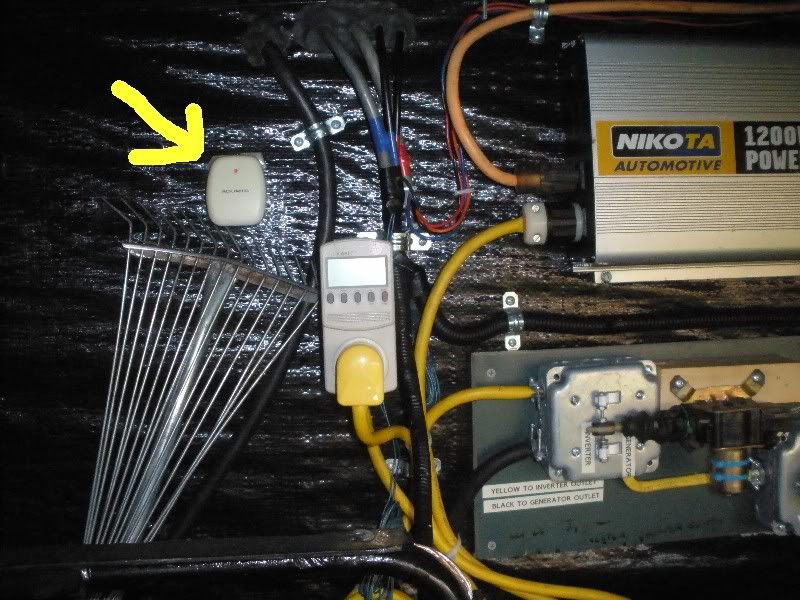

I made some shots of the inside of my “cave” yesterday. You will note the location of the over temperature shut down sensor directly over the engine. The white button thing is a fire alarm sensor. I think it is 140 degrees – but my old, cluttered mind may have gotten the numbers confused with something else. Anyway, it sounds an extremely irritating alarm if it gets too hot. The small white thing on the back wall, near the rake head, is the transmitter for the wireless monitor inside the camper.

You can also see how the exhaust is heat shielded and some “pink stuff” that is supposedly used on the space shuttle as insulation. The claim is it is equal to 12" or more of fiberglass. Can’t vouch that all of these claims are true, but I am using it anyway and it seems to help. I would like to have a couple of square yards of the stuff to experiment with - but all I have is the single square foot shown.

You can also see the Garretson regulator and the trunk solenoid used to prime the mixer. My solenoid does not cut out after 3 seconds – that must be something GM added to the solenoid in later designs. I also use a separate button on my remote for the prime function.

Your set-up looks great! I am anxious to see some temperature vs. load graphs in the future.

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-08-2010 10:57 AM

jlaustin wrote:

1) My LPG converted carb has a 3/16" orifice for the LPG. I've tried 3/16" i.d. Tygon for the vapor line between regulator and carb and the unit runs fine (this was tested with a fully loaded generator). Any reason not to continue to use this? It's rated a "1" for compatibility with propane.

2) No matter which feed block - your design or mine, with a dead cold engine, the remote starter has to try about 4 times to start the engine. It will fire every attempt, but of course when it fires the remote cuts out the starter and that's it until about the fourth attempt. I'm using the GM trunk release solenoid to activate the primer - as I told you, it "cycles" in that it holds down for about 3 seconds, releases for a couple of seconds, then down again, and so on. Do you think it might do better to go the bypass solenoid valve route and get continuous prime until the engine starts? (I'm waiting for the engine to get cold right now so I can manually hold the primer down continuously and see what happens - I'll report back on that.)

I "think" I've discovered the answer to question 1 & 2 ... don't you just hate it when posters answer their own questions?:R

My opinion/experience is that it DOES matter about the vapor line size - this a.m., I went back to the 3/8" i.d. vapor line and didn't change anything else. The vapor line is slightly less than a foot long. When I changed back to the 3/8", the dead-cold engine started on the second crank attempt by the remote starter! (With the 3/16" line, it was taking 4 or 5 attempts).

It always fired with the smaller line, but it seemed to have difficulty sustaining running. My theory is that the larger i.d. line creates a much larger "reservoir" of LPG from the primer and thus doesn't starve the engine before the regulator can sense the demand and release enough gas to "catch-up".

Can anyone think of a better explanation?

I'm still very much interested in opinions on question 3!

Regards,

John

2005 Pilgrim 274RL-5SS

2008 F-250

Amelia - the Welsh Terrier. Daisy, Bonny, & Rosie - the cats!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-07-2010 05:31 AM

professor95 wrote:

Pretty cool, John. I love innovation!

But, to be honest, I am surprised it works. 1/4" is getting pretty small for a load block. My guess would have been it would only have worked with the screw backed out all the way. Anything larger than your 206 cc engine will almost definitely require the regular size load block.

Professor,

After I posted, I went back to my pastime of reading the thread ... I'm up to page 730!!! Somewhere in the "low 700's", I stumbled across the trials and travails of building load blocks! Apparently, there's a lot more to consider than just building a big needle valve! Anyway, the block does work, but I have NOT tested it with a fully loaded-up generator - it might be too small. However, I'm now trying to finalize some things so I can get the unit ready for the summer - maybe more experimentation next winter. I'm sticking with your design for now because I know it works.

Some questions that I think will be of general interest:

1) My LPG converted carb has a 3/16" orifice for the LPG. I've tried 3/16" i.d. Tygon for the vapor line between regulator and carb and the unit runs fine (this was tested with a fully loaded generator). Any reason not to continue to use this? It's rated a "1" for compatibility with propane.

2) No matter which feed block - your design or mine, with a dead cold engine, the remote starter has to try about 4 times to start the engine. It will fire every attempt, but of course when it fires the remote cuts out the starter and that's it until about the fourth attempt. I'm using the GM trunk release solenoid to activate the primer - as I told you, it "cycles" in that it holds down for about 3 seconds, releases for a couple of seconds, then down again, and so on. Do you think it might do better to go the bypass solenoid valve route and get continuous prime until the engine starts? (I'm waiting for the engine to get cold right now so I can manually hold the primer down continuously and see what happens - I'll report back on that.)

3) The DuroPower 3550ES has 4 metal foam-lined enclosure panels around the sides (some have some small vent slits), an open bottom, and normally the top is enclosed, but not tightly, by the gas tank. I've removed the gas tank, lined the inside of the panels with Hardiebacker (covering-over the vent slits), and have a temporary Hardiebacker panel to close the top. I've thoroughly insulated the exhaust/muffler and left it inside (I wanted compactness and the ability to remove the unit from the FW mount without having to dismantle anything). I suspect I'll need some supplementary ventilation or a fan for extreme conditions. Right now I envision putting a hole in the Hardiebacker top above the muffler to simply let the hot escape. Some of the engine cooling air hits the top of the muffler enclosure - I "think" a hole above that area will be even more inducive to a draft effect around the muffler - since it's totally open on the bottom, air should be able to freely rise. Since I'm not at this point going the total enclosure route like one uses to install in a "cave" in a FW (mine is mounted externally on the back of the FW), I don't think I need to go the bottom-mounted fan route. The vent hole in the top would have a cover about 3" above it - a piece of sound-attenutating lined diamond plate or aluminum sheet to provide a cover/lid for the genset - I could leave the periphery beneath the top tubular rails of the genset frame open to let the hot air escape - I would also turn down the edges of the lid to baffle the area somewhat.

Now to get to the question!!!!!

If that doesn't provide sufficient cooling and I need a booster fan, I have a 500 cfm 8" 12vdc (80 watts) "Procomp" fan that I could use to boost the draft above the muffler/generator. It would be desireable to use a temp sensor switch so it can run-on after shut-down until temps are down. I want to move the battery up on top of the genset (build an insulated battery box recessed in the other end of the Hardiebacker top) for ease of maintenance. (Mounted on the receiver hitch/bumper of the FW, the present battery is on the back-side of the genset). Rather than the puny 7 ah gel cell, how about going to something like a wet cell ATV battery (seems they stand abuse pretty well!). Would the trickle charger keep up with all of this, OR, could I tap off the 12v charging circuit off the generator (it puts out 13.5v and is breakered at 8.7 amps) to either charge the battery and/or run the fan???

Regards,

John

2005 Pilgrim 274RL-5SS

2008 F-250

Amelia - the Welsh Terrier. Daisy, Bonny, & Rosie - the cats!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-06-2010 10:43 AM

But, to be honest, I am surprised it works. 1/4" is getting pretty small for a load block. My guess would have been it would only have worked with the screw backed out all the way. Anything larger than your 206 cc engine will almost definitely require the regular size load block.

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-05-2010 05:15 PM

I happened to have an extra 3/8 male x 1/4 female x 1/4 female brass tee and noticed that a ("I think") 1/4 stop nut with a nylon insert would be a press-fit into the 1/4" female threads.

I coated the threads on one end of the tee with silicon RTV, put the nut "upside down" in the opening, and pressed it in with my vise. The threads gave a satisfying "crunch" and the nut seated evenly. I found a suitable screw, tapered the end, and screwed it into the nut. On the opposite end, I have a 1/4 barb x 1/4 fitting, sleeved with a piece of 1/4" o.d. copper tubing, resulting in a 3/16" orifice. The tapered screw fits neatly into the copper orifice and about 3 1/2 turns backed out is a good intial coarse setting to tune the engine.

I've found that the resultant fitting is a little more precise than the alternative and it usually takes more experimentation to get the engine to start intially. Once you find the "sweet spot", it's easy to adjust after that. The only advantages to this method I see are that it eliminates the jam nut and o-ring, the nylon insert provides its own seal and holds the adjustment well, it's smaller and lighter (esthetics creeping in here! HA!), and it's an easy way to make a block if you don't happen to have a tap handy to chase the threads.

Here's a pic of the completed block:

Here's a pic of the "business end". NOTE: The feed block did NOT work very well with this rather blunt taper as seen in this picture! I tapered the screw some more (almost to a sharp point) and it worked much better.

The ultimate taper I wound up with was about twice as long as the one in the above picture and almost came to a sharp point.

Regards,

John

2005 Pilgrim 274RL-5SS

2008 F-250

Amelia - the Welsh Terrier. Daisy, Bonny, & Rosie - the cats!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-04-2010 07:50 AM

jlaustin wrote:

Thanks to all for the temp sensor location, etc.!

A brief followup ... I have the FW over at the house for a few days while the concrete cures in the storage building I'm erecting. I finalized my mount for the DuroPower 3500ES on the back of the FW:

I bought a "Stowaway II" mount (normally used to support a storage bin and rated at 250 lbs capacity) and bolted it to my 2" receiver hitch on the back of the FW. I stabilized it by bolting the ends of the Stowaway mount to the FW's bumper. I repurposed the two rubber feet that came with the genset and put them between the Stowaway frame and the bumper. The result is a very solid mount! The hitch supports the majority of the weight and the bumper just serves as a stabilizer to prevent side-to-side sway.

Also, I ran some tests today on the DuroPower's ability to power the FW (LPG conversion). I plugged into the 30 amp receptacle, started the A/C fan first, then the 15K BTU A/C. The generator seemed unfazed and purred along at 120v. I turned on my 32" Samsung LCD HDTV (it only pulls about 80w) and no noticeable change in the genset or voltage. Turned on the fridge - again, no change. HOWEVER, turned on the microwave and the genset really sounded like it was lugging, the voltage dropped to about 105, and the A/C sounded like it was lugging, too. Soooo, sounds like plenty of power, just turn off the A/C when you want to run the microwave - no biggee!

I've got some tweaking to do of the sound abatement and then I'm going to assess whether the open bottom is adequate as-is or whether I need to add a supplementary fan.

BTW, I've also hit on an even easier way to build a LPG feed-block. I want to do some testing and then I'll post the details.

Regards,

John

1* 2008 Brookside by Sunnybrook 32'

1* 2002 F250 Super Duty 7.3L PSD

Husky 16K hitch, Tekonsha P3,

Firestone Ride Rite Air Springs, Trailair Equa-Flex, Champion C46540

"A bad day camping is better than a good day at work!"

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-04-2010 05:27 AM

Nice to see a post from you again. Now, that I think about the location of a sensor at the genhead exhaust, seems reasonable and another on the cylinder head. Under heavy load, the temp on my cylinder head did rise to 220 degrees with 90 degrees ambient and on the cover of the genhead to 200 degrees ( just luck I guess it didn't burn out) with the DP 3500EC in a well ventilated enclosure in the factory genset compartmant of the old MH. With these temps, the genset would shut down after about 20 minutes with a load above 21 amps. I never checked the genhead exhaust temp. That would have been interesting. My Champion is now back to stock, in the genhouse, so when we have a 90 degree day I will check the temp of the genhead exhaust with a load of 3000w and see what I get and how long it will operate.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-04-2010 04:24 AM

jlaustin wrote:

Thanks to all for the temp sensor location, etc.!

A brief followup ... I have the FW over at the house for a few days while the concrete cures in the storage building I'm erecting. I finalized my mount for the DuroPower 3500ES on the back of the FW:

I bought a "Stowaway II" mount (normally used to support a storage bin and rated at 250 lbs capacity) and bolted it to my 2" receiver hitch on the back of the FW. I stabilized it by bolting the ends of the Stowaway mount to the FW's bumper. I repurposed the two rubber feet that came with the genset and put them between the Stowaway frame and the bumper. The result is a very solid mount! The hitch supports the majority of the weight and the bumper just serves as a stabilizer to prevent side-to-side sway.

Also, I ran some tests today on the DuroPower's ability to power the FW (LPG conversion). I plugged into the 30 amp receptacle, started the A/C fan first, then the 15K BTU A/C. The generator seemed unfazed and purred along at 120v. I turned on my 32" Samsung LCD HDTV (it only pulls about 80w) and no noticeable change in the genset or voltage. Turned on the fridge - again, no change. HOWEVER, turned on the microwave and the genset really sounded like it was lugging, the voltage dropped to about 105, and the A/C sounded like it was lugging, too. Soooo, sounds like plenty of power, just turn off the A/C when you want to run the microwave - no biggee!

I've got some tweaking to do of the sound abatement and then I'm going to assess whether the open bottom is adequate as-is or whether I need to add a supplementary fan.

BTW, I've also hit on an even easier way to build a LPG feed-block. I want to do some testing and then I'll post the details.

Regards,

John

Hey John,

I tested temp sensor locations and settled on mounting a temp sensor under the gen head where the gen head fan air exits. I figure generator head temp is what I want to know as per the professors advice. I do have a sensor on the cylinder head but the gen head temp is what I worry about and is what is displayed on my gauge inside the rv.

Brad

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-03-2010 04:44 PM

A brief followup ... I have the FW over at the house for a few days while the concrete cures in the storage building I'm erecting. I finalized my mount for the DuroPower 3500ES on the back of the FW:

I bought a "Stowaway II" mount (normally used to support a storage bin and rated at 250 lbs capacity) and bolted it to my 2" receiver hitch on the back of the FW. I stabilized it by bolting the ends of the Stowaway mount to the FW's bumper. I repurposed the two rubber feet that came with the genset and put them between the Stowaway frame and the bumper. The result is a very solid mount! The hitch supports the majority of the weight and the bumper just serves as a stabilizer to prevent side-to-side sway.

Also, I ran some tests today on the DuroPower's ability to power the FW (LPG conversion). I plugged into the 30 amp receptacle, started the A/C fan first, then the 15K BTU A/C. The generator seemed unfazed and purred along at 120v. I turned on my 32" Samsung LCD HDTV (it only pulls about 80w) and no noticeable change in the genset or voltage. Turned on the fridge - again, no change. HOWEVER, turned on the microwave and the genset really sounded like it was lugging, the voltage dropped to about 105, and the A/C sounded like it was lugging, too. Soooo, sounds like plenty of power, just turn off the A/C when you want to run the microwave - no biggee!

I've got some tweaking to do of the sound abatement and then I'm going to assess whether the open bottom is adequate as-is or whether I need to add a supplementary fan.

BTW, I've also hit on an even easier way to build a LPG feed-block. I want to do some testing and then I'll post the details.

Regards,

John

2005 Pilgrim 274RL-5SS

2008 F-250

Amelia - the Welsh Terrier. Daisy, Bonny, & Rosie - the cats!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-02-2010 05:07 PM

jlaustin wrote:

Professor,

Just to be sure I've got this right - you put the probe in the exit air "away from the exhaust" - I'm assuming you mean away from the engine exhaust, of course, but the probe is in the "exhaust"/exit air coming from the generator, correct?

I do happen to have an adjustable temp switch that I eventually intended to wire-in as an emergency overtemp shut-down. Can you be a little more specific where to put it "over the cylinder" (i.e., location and distance from fin, etc?)

Regards,

John

John,

I have a regular wireless indoor/outdoor thermometer sensor mounted in the "Cave" near the generator that monitors ambient air temperature, mostly radiant, with a receiver inside the camper. I use this for visually monitoring the compartment temperature. It is cheap, handy and effective.

Under the generator in the pathway for air moving after the overall cooling (before the exhaust fan) is an adjustable sensor that will sound a piezo alarm if the exit air exceeds 160 degrees F.

Directly over the engine cylinder, approximately 1" removed, is a 180 degree automotive fan switch that will shut down the generator if it should close. It is connected to the low oil cut-off switch.

All of these positions are "relative" to my install. As Floyd suggested, perhaps putting a sensor directly on the alternator shell may be appropriate. In any event, we need to keep the alternator under 190 degrees - preferably well under. Exhaust pipe temperatures will naturally be high and can give erroneous readings. Therefore, I prefer to keep any sensors well away from the exhaust pipe (or muffler).

Changing gears for a moment......

My comment on our toys not being adequate for running a 15K BTU rooftop RV air conditioner on an upper 90 degree day was not intended to be exclusive to Chinese 3,000 watt class generators. Any 3,000 watt class generator will be overtaxed when called upon to run such an A/C unit when the compressor is locked in continuously while trying to keep a RV cool on a super hot day. This includes Honda, Yamaha, etc. that are in the 3,000 to 3,500 watt class - inverter or synchronous. It would take a 5,000 watt or larger unit to operate in extreme temperatures at a 100% loaded duty cycle. I have discussed this before, many pages back, but with summer heat approaching I just don't want anyone expecting more to be disappointed.

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-02-2010 10:33 AM

jlaustin wrote:professor95 wrote:

Depends......

If you have an adjustable thermostat like the Fenwall I have you can put it most anywhere.

If you use a fixed temperature switch like a 180 degree sensor from a car over the cylinder is a good location.

We are looking at two different things. One is high temperature shut down, the second is measuring/monitoring temperature.

I have found if the air temperature inside the enclosure, near the generator, goes over 160 degrees we have a problem. You can monitor this at most any point in the air flow exit path away from the exhaust. Just keep in mind that if the air temp is over 160 the temperature inside the alternator is well over 190, which is the break down point for the armature windings enamel insulation.

...

Professor,

Just to be sure I've got this right - you put the probe in the exit air "away from the exhaust" - I'm assuming you mean away from the engine exhaust, of course, but the probe is in the "exhaust"/exit air coming from the generator, correct?

I do happen to have an adjustable temp switch that I eventually intended to wire-in as an emergency overtemp shut-down. Can you be a little more specific where to put it "over the cylinder" (i.e., location and distance from fin, etc?)

Regards,

John

More thought here. If the idea is to protect the armature windings from over temperature, then why not locate the probe in/on the aluminum casing of the genhead? What else is to be protected from overheating? There is no more fuel tank? Prof has said, 140 degrees is max for the fuel tank.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-02-2010 09:54 AM

professor95 wrote:

Depends......

If you have an adjustable thermostat like the Fenwall I have you can put it most anywhere.

If you use a fixed temperature switch like a 180 degree sensor from a car over the cylinder is a good location.

We are looking at two different things. One is high temperature shut down, the second is measuring/monitoring temperature.

I have found if the air temperature inside the enclosure, near the generator, goes over 160 degrees we have a problem. You can monitor this at most any point in the air flow exit path away from the exhaust. Just keep in mind that if the air temp is over 160 the temperature inside the alternator is well over 190, which is the break down point for the armature windings enamel insulation.

...

Professor,

Just to be sure I've got this right - you put the probe in the exit air "away from the exhaust" - I'm assuming you mean away from the engine exhaust, of course, but the probe is in the "exhaust"/exit air coming from the generator, correct?

I do happen to have an adjustable temp switch that I eventually intended to wire-in as an emergency overtemp shut-down. Can you be a little more specific where to put it "over the cylinder" (i.e., location and distance from fin, etc?)

Regards,

John

2005 Pilgrim 274RL-5SS

2008 F-250

Amelia - the Welsh Terrier. Daisy, Bonny, & Rosie - the cats!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-02-2010 06:29 AM

professor95 wrote:jlaustin wrote:MrWizard wrote:

If me , I would follow the Professor's example with the cylinder ?, this is where the heat is generated 'pun intended' and you don't want the engine to overheat & seize, if the engine temp is where it belongs, then everywhere else should also be OK.

I'm only up to page 626 on attempting to catch up on the thread!:B

Is there a recommended location for the probe on the cylinder - it's going to be very different out on a fin versus deep between the fins, or, in the direct path of the cooling air versus out of the airstream?

Regards,

John

Depends......

If you have an adjustable thermostat like the Fenwall I have you can put it most anywhere.

If you use a fixed temperature switch like a 180 degree sensor from a car over the cylinder is a good location.

We are looking at two different things. One is high temperature shut down, the second is measuring/monitoring temperature.

I have found if the air temperature inside the enclosure, near the generator, goes over 160 degrees we have a problem. You can monitor this at most any point in the air flow exit path away from the exhaust. Just keep in mind that if the air temp is over 160 the temperature inside the alternator is well over 190, which is the break down point for the armature windings enamel insulation.

I did hit 150 in the "cave" last summer running the A/C for a long period of time. I got worried but it did not go higher. You could smell the results of the heat - which was disconcerting to me.

One thing you MUST remember is as the outside temps go up, cooling is reduced - even with a stock outside Chinese genny. Additionally, as the temps go up we want more cold from the A/C which imposes a heavier load on the genny and generates even more heat. Truth is the Chinese gennys we play with are not really adequate for running a 15,000 BTU A/C on an RV for long periods of time when the outside temperatures are in the upper 90's - no matter where they are located. This is one of the reasons I converted a 6,000 BTU window unit to fit in a Dometic RV rooftop cabinet for the bedroom in the fiver. At least we do not go to bed with sweat rolling off our bodies on those near 100 degree days.

A generator is the common thread to all RV type folks. When you think about it, a $300, 3000w Chinese Genset and over 600,000 hits to this thread, that had it's begining ( weaving ) over five years ago, will make you scratch your head, saying 'how did you do it'. And no end in sight. Professor95 has inspired many to think outside of the box with other 'add ons' like the 6,000 BTU A/C retro. I followed that link for a while, that was interesting. It fits well with the 3000w gen and must be almost as quiet as a mouse. For me, I had the desire to follow through with the same retro, but lack to skill. Still trying to figure a way to add a 6,000 BTU A/C in the MH bed room, some way some how. As for my Champion, the add on Electric start and retro to LPG has worked out quite well. Thanks again Prof, for all the inspiration, with 'show and tell' ~

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-01-2010 06:03 PM

jlaustin wrote:MrWizard wrote:

If me , I would follow the Professor's example with the cylinder ?, this is where the heat is generated 'pun intended' and you don't want the engine to overheat & seize, if the engine temp is where it belongs, then everywhere else should also be OK.

I'm only up to page 626 on attempting to catch up on the thread!:B

Is there a recommended location for the probe on the cylinder - it's going to be very different out on a fin versus deep between the fins, or, in the direct path of the cooling air versus out of the airstream?

Regards,

John

Depends......

If you have an adjustable thermostat like the Fenwall I have you can put it most anywhere.

If you use a fixed temperature switch like a 180 degree sensor from a car over the cylinder is a good location.

We are looking at two different things. One is high temperature shut down, the second is measuring/monitoring temperature.

I have found if the air temperature inside the enclosure, near the generator, goes over 160 degrees we have a problem. You can monitor this at most any point in the air flow exit path away from the exhaust. Just keep in mind that if the air temp is over 160 the temperature inside the alternator is well over 190, which is the break down point for the armature windings enamel insulation.

I did hit 150 in the "cave" last summer running the A/C for a long period of time. I got worried but it did not go higher. You could smell the results of the heat - which was disconcerting to me.

One thing you MUST remember is as the outside temps go up, cooling is reduced - even with a stock outside Chinese genny. Additionally, as the temps go up we want more cold from the A/C which imposes a heavier load on the genny and generates even more heat. Truth is the Chinese gennys we play with are not really adequate for running a 15,000 BTU A/C on an RV for long periods of time when the outside temperatures are in the upper 90's - no matter where they are located. This is one of the reasons I converted a 6,000 BTU window unit to fit in a Dometic RV rooftop cabinet for the bedroom in the fiver. At least we do not go to bed with sweat rolling off our bodies on those near 100 degree days.

2009 Cedar Creek 5th Wheel - 2004 Volvo VNL670 class 8 MotorHome conversion as toter.

Turbocharged, 12L, 465 HP and 1,800 ft. Lbs. of torque.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Apr-01-2010 02:57 PM

2015 Keystone Raptor 332TS 5th wheel toy Hauler (sold)

2004 Winnebago Vectra. 2011 Jeep Grand Cherokee toad