- Good Sam Community

- Everything RV

- Technical Issues

- Mysterious Propane "Leak"

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Mysterious Propane "Leak"

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-08-2022 12:26 PM

After 5 years or so my propane pigtails had hardened. Since the regulator was the original from 2004, I decided I should replace it also. What motivated both was what seem to be very slow leak. I left one of my half empty propane tanks with the valve open but without using any propane for several months. When I finally checked the tank was empty. I put in a new tank, charged the propane lines, ran both the stove and the furnace. I shut off the tank and noticed the regulator showed red after a couple hours. I switched the regulator to the other tank, opened and then closed the valve and again the regulator showed red in a couple of hours.

After changing the regulator and pigtails. I did a careful leak test. No soap bubbles and absolutely no propane odor. This time, I used the stove and furnace and then shut the valves. I expected to see a green indicator on the regulator for many hours. Instead it changed to red in well under 2 hours. I switched over and had the same results with the other tank. I did several checks and the pattern repeated with about 1 1/2 hours until the regulator changed from green to red. I checked for odors and leaks everywhere with no problems.

It has now been several days since I replaced the regulator and pigtails. Last night I did another test and the regulator was still green after 4 hours when I went to bed. Today I did another check and it took 8 hours for the regulator to show red.

Any ideas that can explain this or point to additional testing?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-18-2022 09:44 AM

However, note that the temperature is what changed…

3 tons

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-18-2022 07:52 AM

2017 Heartland Torque T29 - Sold.

Couple of Arctic Fox TCs - Sold

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-18-2022 07:46 AM

When I first replaced pigtails and the regulator, after shutting off the tank, the empty indicator on the regulator showed red in 2 hours of less. I think I check that several times. A day or so later, I tested and found the indicator took 6-8 hours to turn red.

The tank has been open for the past 10 days with no other work and no appliances in use. I tried another leak test. I went to bed 14 hours after shutting off the tank and the indicator was still green. This morning after 20 hours and a 15 degree drop in temperature, the indicator was red.

So how does the leak test go from under 2 hours to 6 hours and now to over 14 hours without any changes?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-17-2022 05:57 AM

Grit dog wrote:3 tons wrote:Grit dog wrote:3 tons wrote:

My camper has been sitting for about a month with the propane bottle shut off. After each use, I first shut off the appliances before shutting off the tank valve, because the camper rest in our RV garage…FWIW, after all this time I just checked and the regulator valve is still showing green…

The one thing that I can say is that teflon tape is not intended for use on any of the threaded brass fittings having tapered-ends…

3 tons

You included an extra word when you said “not” in the last sentence.

Hopefully no one follows those directions and just tries to crank pipe thread fittings together without tape or pipe dope….

Wrong, the operative word I used is ‘tapered’ (meaning a compression fitting)…With this type fitting no teflon or pipe dope is used because it might interfere with the compression seal, thereby resulting in a leak…Compression is what does the sealing-in of the gas (and why their use for gases…), threads are not what does the sealing…

For an example check this out at about 13 min in:

https://www.youtube.com/watch?v=oBRMRAZykJs

3 tons

10-4.

Flare or compression fittings. Yup.

I read as tapered threads.

Apologies.

No apologies needed, lots of understandable confusion about this, additional clarity is warranted.

3 tons

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-17-2022 04:35 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-16-2022 09:15 PM

Sometimes it is better to ask for clarification, then throwing darts in words.

I have been building machines for 40 years, in both the machine tool and food industries. Each industry has different slang and names for things that are used every day in their respective industry.

When brass machined fittings are called out, the ends of the fitting can have several names used by tradesmen.

NPT in the US I think we can all agree on, has tapered threads on pipe and fittings that require a thread sealant when making a pressure seal.

We also have other fittings that have tapered ends on them that are made out of brass, steel, plastic and other materials. The tapered ends are part of a compression seal setup that does "not" require sealant in the joint. The pipe or tube used to join with the tapered end fitting, has a flared taper on it to match the fitting and create a pressure tight seal without sealant.

Now to common brass fittings used in LP gas systems used in campers. There are a variety of them, some are all NPT tapered thread on all ends, while others can have only tapered flare ends or a combination of both. Here is where the joint naming can be miss read as the word taper shows up in both cases and may means something different pending ones background.

To me, a brass adapter fitting with a tapered end on it, I call it a flare fitting, not a tapered end fitting as that is from my background and industry I worked in. Other industries may call them out differently.

If any one has heard of Parker, they are one of the big fitting manufactures I used that they refer to them as flared fittings also. Again in the industry I have worked in. Other industries may call them something else.

There is 37 degree flare style made from steel for high pressure, https://ph.parker.com/us/en/37-flare-fittings

And there is 45 degree flare for lower pressure and the LP gas fittings we find in our campers. https://ph.parker.com/us/en/45-flare-fittings

A brass adapter fitting could have NPT tapered thread on one end and a 45 degree flared male or female connection on the other end. You use thread sealant on the NPT end and no sealant on the flared end.

While a flared fitting has a taper on the end, in the industries I come from, the taper word is not used in the call out, we use the word flare or flared end.

Hope this helps

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-16-2022 08:41 PM

3 tons wrote:Grit dog wrote:3 tons wrote:

My camper has been sitting for about a month with the propane bottle shut off. After each use, I first shut off the appliances before shutting off the tank valve, because the camper rest in our RV garage…FWIW, after all this time I just checked and the regulator valve is still showing green…

The one thing that I can say is that teflon tape is not intended for use on any of the threaded brass fittings having tapered-ends…

3 tons

You included an extra word when you said “not” in the last sentence.

Hopefully no one follows those directions and just tries to crank pipe thread fittings together without tape or pipe dope….

Wrong, the operative word I used is ‘tapered’ (meaning a compression fitting)…With this type fitting no teflon or pipe dope is used because it might interfere with the compression seal, thereby resulting in a leak…Compression is what does the sealing-in of the gas (and why their use for gases…), threads are not what does the sealing…

For an example check this out at about 13 min in:

https://www.youtube.com/watch?v=oBRMRAZykJs

3 tons

10-4.

Flare or compression fittings. Yup.

I read as tapered threads.

Apologies.

2017 Heartland Torque T29 - Sold.

Couple of Arctic Fox TCs - Sold

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-16-2022 06:46 PM

3 tons wrote:Grit dog wrote:3 tons wrote:

My camper has been sitting for about a month with the propane bottle shut off. After each use, I first shut off the appliances before shutting off the tank valve, because the camper rest in our RV garage…FWIW, after all this time I just checked and the regulator valve is still showing green…

The one thing that I can say is that teflon tape is not intended for use on any of the threaded brass fittings having tapered-ends…

3 tons

You included an extra word when you said “not” in the last sentence.

Hopefully no one follows those directions and just tries to crank pipe thread fittings together without tape or pipe dope….

Wrong, the operative word I used is ‘tapered’ (meaning a compression fitting)…With this type fitting no teflon or pipe dope is used because it might interfere with the compression seal, thereby resulting in a leak…Compression is what does the sealing-in of the gas (and why their use for gases…), threads are not what does the sealing…

For an example check this out at about 13 min in:

https://www.youtube.com/watch?v=oBRMRAZykJs

3 tons

Ummm, NPT threads are tapered and definitely need PTFE tape or pipe dope. You are confusing tapered (e.g. NPT threads) and compression fittings. Those are definitely not the same. As a matter of fact, while folks think NPT means National Pipe Thread, it does not. It actually means National Pipe Tapered.

CPC website

2017 F-150 XLT 4x4 SuperCab w/Max Tow Package 3.5l EcoBoost V6

2017 Airstream Flying Cloud 23FB

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-16-2022 05:56 PM

I have not used my RV in over a year and barely used it since Covid started. After my month long test I plan to cycle the furnace, stove, HW heater and check afterwards using the switch over indicator.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-16-2022 05:04 PM

JimK-NY wrote:

John, thanks for the impressive detailed information. I know for sure I would like to avoid tackling all of these possible issues. At this point I am trying to assess the amount of leakage. I weighed my primary tank and have had it opened for 10 days. In another couple of weeks, I will do a weight check. I did check the HW heater again and think there is a very, very faint odor. So if I decide to do more checking and possible repairs, I will start there.

Thanks again.

Hi Jim,

Thanks for the good words.

What are your thoughts on what you will do with your 10 day weight loss test when you find the number? What will you declare as good or bad? As I said above, anytime I check an older camper LP system, odds are high something has a fine leak or leaks that can fail the standard pressure drop test. Once you know, you sort of have to go hunting and find it and correct it.

I agree, the water heater gas valve is suspect, you can move the gas burner tube off the end of the valve, charge the system with gas, and use leak solution on the brass tip of the valve. If it blows bubbles, it leaks. Odds are favorable, yours will have some level of leak.

Here is a post of mine from March of 2006 when I started into chasing camper LP leaks. It also shows capping off appliances to hunt down what is causing what leak or leaks. There is some good info there and some real good responses from other posters which may help you. https://www.rv.net/forum/index.cfm/fuseaction/thread/tid/17306270/srt/pa/pging/1/page/1.cfm

An interesting one is by Chris Bryant almost all the way down the second page where he posted that about leak rate on the water heater valve. See here for a direct link to it. http://www.rv.net/forum/index.cfm/fuseaction/thread/tid/17306270/gotomsg/17334969.cfm#17334969

Hope this helps and let us know how you come out on this.

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-16-2022 02:57 PM

Grit dog wrote:3 tons wrote:

My camper has been sitting for about a month with the propane bottle shut off. After each use, I first shut off the appliances before shutting off the tank valve, because the camper rest in our RV garage…FWIW, after all this time I just checked and the regulator valve is still showing green…

The one thing that I can say is that teflon tape is not intended for use on any of the threaded brass fittings having tapered-ends…

3 tons

You included an extra word when you said “not” in the last sentence.

Hopefully no one follows those directions and just tries to crank pipe thread fittings together without tape or pipe dope….

Wrong, the operative word I used is ‘tapered’ (meaning a compression fitting)…With this type fitting no teflon or pipe dope is used because it might interfere with the compression seal, thereby resulting in a leak…Compression is what does the sealing-in of the gas (and why their use for gases…), threads are not what does the sealing…

For an example check this out at about 13 min in:

https://www.youtube.com/watch?v=oBRMRAZykJs

3 tons

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-16-2022 02:23 PM

Thanks again.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-16-2022 09:54 AM

JimK-NY wrote:

Thanks for the reply. Sorry for the delay but I just got out of the hospital. The camper is a Northstar Igloo. I think it was sold as a 2005 model but actually built in 2004. I am positive the HW heater is Atwood. I believe the furnace is also Atwood but cannot check on that or the stove top until I am able to climb stairs in a couple of days. The is no connection for a BBQ grill and the refrigerator is compressor.

I used it a couple of years as a fulltimer but since then it has been stored in the winter outdoors in Long Island, NY. Repairs have been minimal. I replaced the ignitor on the HW heater. I have replaced the pigtails every 2-3 years due to hardening. In addition to replacing the pigtails last month, I also decided to replace the switch over regulator due to age.

Hi Jim,

Hope you are doing well now, no worries on a later reply.

On the older campers, (20 year range +/-) there was a trend at the time by the RV manufacturer's to stick with certain brands for both quality and pricing on what that appliance manufacture offered.

It appears in your case, Atwood Mobile was the choice for the water heater, odds are high the furnace and the range. The fridge and AC unit could be Dometic as they offered both, or they split up in Norcold fridge and Coleman Mach AC.

I do total camper restorations & localized water damage repair as a somewhat extreme retirement hobby. Water damage is the main issue requiring restoration, but I go through every appliance and mechanical running gear etc. in this restore process. Most all these campers are in the 15 to 20 year old range which is about where yours is at. I do not do this for a living, so my sample set is close to 20 campers so far for this information. We have a few RV tech's on the forum who may have lots of years on this to confirm what I have been seeing.

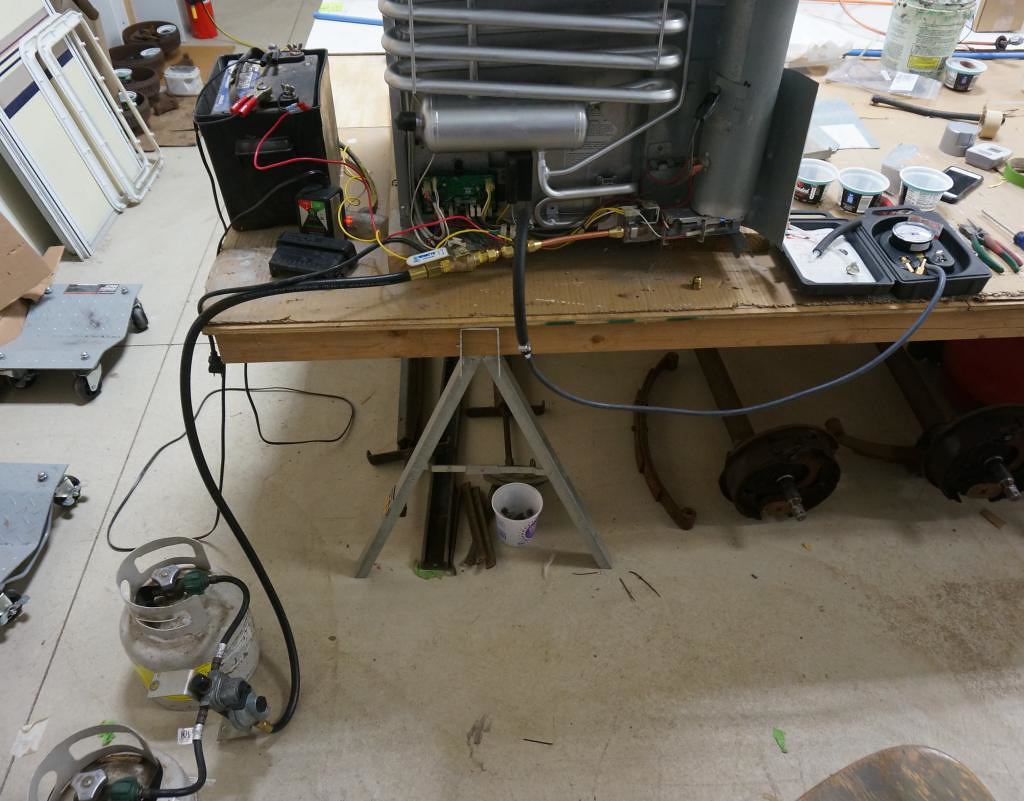

In this restoration process, I normally end up pulling all appliances out of the camper that are mounted in the siding to do a bench test, clean up and repair on all of them. I have to fix the rot, so out comes the siding mounted appliances. When it comes to the LP system, I test each appliance separate and then as a complete system. There are 3 tests to make this complete and I use either a manometer or a precision LP gas gauge. The gauge is quicker, but if a question comes up, I verify it with the manometer.

You could very well have small LP leak or leaks on the appliances. In fact, I have yet to restore a 20 year old vintage camper without some LP gas leak somewhere.

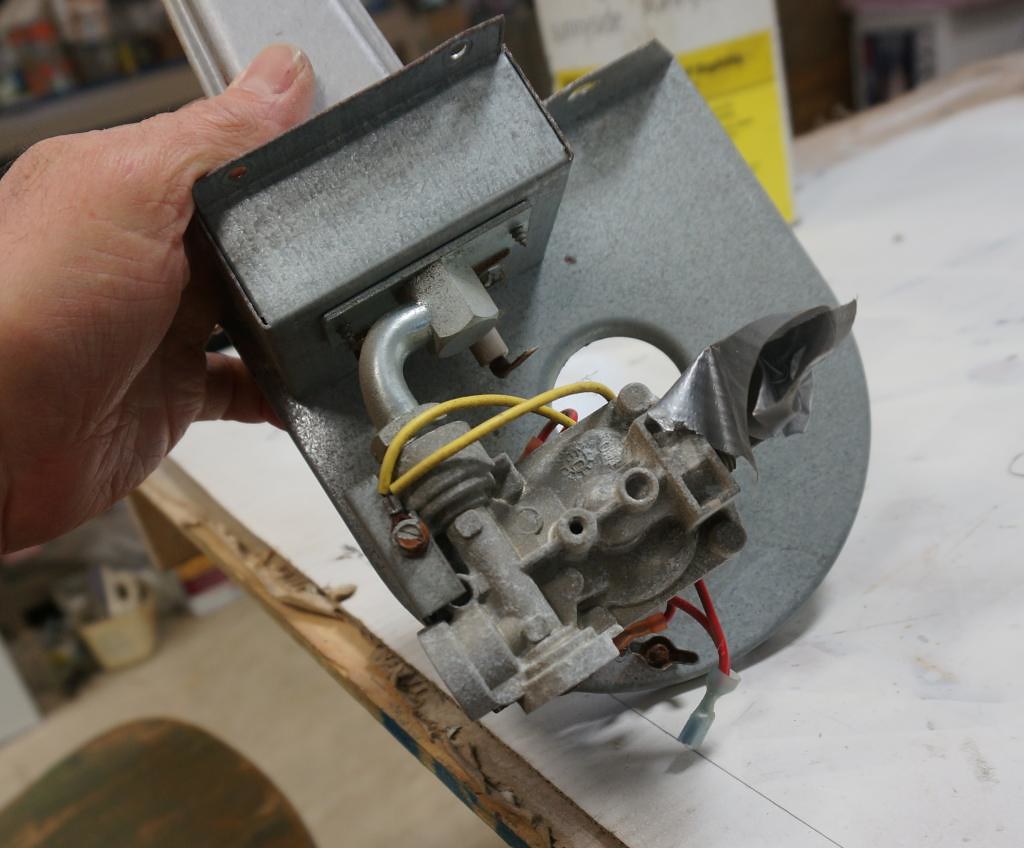

Lets start with the furnace. The gas valve leaking is about a 50/50 issue with a fine leak. This may be aggravated by the camper not being used in a long time. When the outside of the valve has corrosion fuzz on it, odds are not good for it. While the valve tests great for no leaks at the start, once the valve is cycled, tests there after show it does not always seal up tight. See the pics from the bench test.

The fuzz on the outside of the valve.

The bench test setup using the gas gauge.

Confirming the leak at the valve

I even test the new valve before installing. They do work from the start thankfully.

These RV LP gas valves are not rebuildable, all you can do is replace them. I suspect what happens is, being stored outside in an unheated space, spring time condensation sweat when the metal was cold, then started to warm up, starts the bare aluminum into a corrosion cycle. You being in NY and I am in OH, that cold/frozen and warm thaw cycle happens. The valve internally gets a small level of corrosion on the valve seat and it will allow a fine leak. All I can do is replace the valve and move on.

The Atwood water heater has the issue worse I think as the valve is closer to outside for corrosion. See here,

The gas valve out on the bench test. When they look like this, odds are high they will fail the LP leak test.

After cleaning up the heater and the outside of the gas valve, I do the LP test.

Yes, it leaks, the bubble test shows the location after the gage test fails.

New valve next to old, replace, retest, and all works well and passes.

New valve installed and under use testing

The Atwood stove, since it is inside the camper, the burner knobs I have not had much issue with. But the stove regulator, I can have a diaphragm leak. This leak was on a newer camper, only about 2 - 3 years old at the time. I'll leave the new Dometic non working stove regulator issue for another time.

The Domectic fridge, it uses a different type of gas valve. So far I have not had the fridge gas valves fail the leak test, even when 20 years old. I'm sure they can, but they do not seem to be as pronounced as the water heater being the worst, then the furnace.

Cleaned up mounting bracket on the old gas valve.

Leak check

Live test

When the camper is all back together, I do a total system LP test. This checks for anything in the system for leaks and tests the main tank regulator.

I do these 3 tests.

1. System pressure drop test. I hook up the gauge at a stove burner as it is easier to get into the system. You charge the system, shut off both LP tanks, bleed the pressure down to 8" WC to open the main tank regulator and then wait and look for a pressure drop. The time length may change by state etc. For sure nothing less then 3 minutes and no drop at all. I test longer into the 15 minute time period. After doing the bench tests, I normally have no issue passing 15 minutes. But, the main tank regulator and the hoses are always suspect. If the hoses are hard as a rock, I change them before I start. I have had many main tank regulators be bad, for regulation more then diaphragm Leaks.

2. Main regulator pressure set point test. Next if I have no leaks, I do the main system pressure setpoint. Here I need to get upstream of the stove regulator. Since I was on the gas burner control I have the down stream stove regulator pressure already, but I do not totally know the main system pressure. If I can get my 11" WC on the main pressure, I'm good to the next test. This can be where I start finding main tank regulators be bad. I adjust the main tank regulator as needed to get up to or down to 11" WC.

3. Main regulator lock up or max pressure test. This test point is still at the stove upstream of the stove regulator, but it tests the max pressure when the furnace and water heater are in operation. You do not want above 14" WC or a lot below 11"WC. This is where an old or sometimes new, tank regulators fails the test. A 20 year old RV style tank regulator is often a problem. Not always, but often. The system will not maintain stable enough not not go above or below the limits. Trying to adjust the setpoint is all you can do. So you replace the main tank regulator and start over on the leak checks and go again through the test.

The tanks hose fittings, either on the high side or the low pressure side have been a leaks source at the fittings. The main LP gas line sch 40 black iron pipe joints normally come out OK. The 3/8" copper hook up tubes to the appliance, if they are loose, they can leak. Leak bubble solution finds them.

The end results of my learnings are, RV grade LP gas components are not high quality like in a home or industry. Everything is throw away and not the greatest quality even when new. It's sad. I also see new campers being built now with flex rubber lines in place of older hard lines. I'm not sure I really like that idea. They are faster to install, but longevity the jury is out, along with the oil in the hose issues that can come from rubber lines.

Hope this helps

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-15-2022 11:08 AM

JBarca wrote:

Hi JimK,

It appears your camper was made in 2004, that is an older camper at this point in time. A few questions as I may be able to explain some of what you are seeing, but we need more background info to be more specific.

1. Is your camper a 2004?

2. What brand and model are these appliances,

Water heater

Furnace

Stove/range

Fridge

Outside LP gas tap off the main gas line for a grill with a quick disconnect, do you have one?

I have tested a good number of older Atwood and Dometic products that are in the age of a 2004 camper and found several common trends. While Suburban/Norcold may have the same issues, I do not have as much data from those.

3. What state in the US is the camper stored at over the winter?

4. Is your camper stored inside a heated building or outside?

5. Have you or a dealer, ever replaced any gas appliance parts other then your new regulator and pigtails? If so, what parts did they replace?

I'll type out my findings as I restore older campers, but I want to make sure they are close to what you have, and we need more specific info to give better answers to help answer where very slow leaks can occur.

Hope this helps,

John

Thanks for the reply. Sorry for the delay but I just got out of the hospital. The camper is a Northstar Igloo. I think it was sold as a 2005 model but actually built in 2004. I am positive the HW heater is Atwood. I believe the furnace is also Atwood but cannot check on that or the stove top until I am able to climb stairs in a couple of days. The is no connection for a BBQ grill and the refrigerator is compressor.

I used it a couple of years as a fulltimer but since then it has been stored in the winter outdoors in Long Island, NY. Repairs have been minimal. I replaced the ignitor on the HW heater. I have replaced the pigtails every 2-3 years due to hardening. In addition to replacing the pigtails last month, I also decided to replace the switch over regulator due to age.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-14-2022 11:24 PM

3 tons wrote:

My camper has been sitting for about a month with the propane bottle shut off. After each use, I first shut off the appliances before shutting off the tank valve, because the camper rest in our RV garage…FWIW, after all this time I just checked and the regulator valve is still showing green…

The one thing that I can say is that teflon tape is not intended for use on any of the threaded brass fittings having tapered-ends…

3 tons

You included an extra word when you said “not” in the last sentence.

Hopefully no one follows those directions and just tries to crank pipe thread fittings together without tape or pipe dope….

2017 Heartland Torque T29 - Sold.

Couple of Arctic Fox TCs - Sold