- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- Best Fix for a little sealant delamination Front C...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Best Fix for a little sealant delamination Front Cap

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-02-2014 07:51 AM

2003 F350 6.0L 4X4 DRW, Oil bypass filter, Coolant Filter, Blue Spring fuel pressure mod, DELO ELC, DashBoss Bluetooth engine monitor, EGT/FP gauge, SuperSprings, torklift hitch/tiedowns, 48" SuperTruss, fastguns, Kenwood CMOS Backup Camera.

- Labels:

-

Truck Campers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-04-2014 08:42 AM

2003 F350 6.0L 4X4 DRW, Oil bypass filter, Coolant Filter, Blue Spring fuel pressure mod, DELO ELC, DashBoss Bluetooth engine monitor, EGT/FP gauge, SuperSprings, torklift hitch/tiedowns, 48" SuperTruss, fastguns, Kenwood CMOS Backup Camera.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-03-2014 07:34 AM

WyoTraveler wrote:

You can also use eterna bond tape along with icor self leveling caulk. Really needs attention before damage increases.

Agreed, Eterna Bond alone will do it but I would go chaulking also.

https://af996travels.wordpress.com/

05 DMAX 2500HD with lots of stuff

2013 AF 996

73 FJ40 Landcruiser

72 Honda Trail 70

05 Kawasaki 700 quad

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-03-2014 07:22 AM

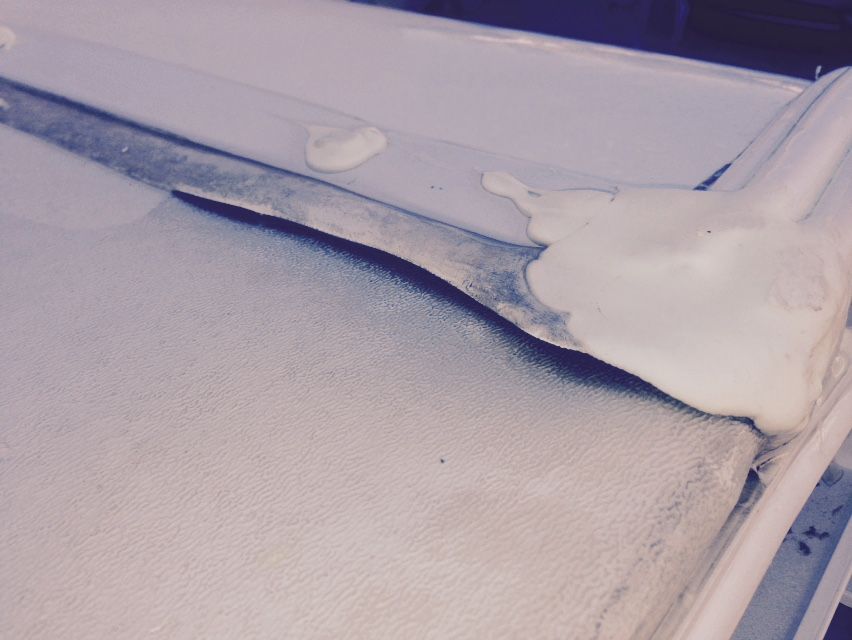

After taking mine apart with the help of an out of state AF dealer , I saw how the mfg. lapped the roof layers on their units.

The dealer offered a solution to the AF mfg. many times over the years, as he rebuilt the nose caps on a lot of his units. He changed the direction of the layering and sealed the edges of the filon before sealing it up.

After he did that, none came back leaking. As for his method of repair, it all fell on deaf ears as far as AF was concerned.

The downward slope of the AF cab-over roof allows water to gather at that seem when the unit is parked stationary.

Being that this is how most campers spend most of their life (parked) you would think the roof layers (shingles) would be lapped like a roof on your house, to shed water .

AF believes they should lapped in the opposite direction allowing water to shed while your driving in the rain at 60 mph .

Driving in the rain all of the TC's life , it would probably not delaminate . After you seal it you might want to consider moving to a wet climate and drive it 24/7 , they were designed to work that way . 🙂

Once the ends of the filon are penetrated by water its over.

The filon has a cardboard backing in order for it to bend. That cardboard like backing soaks up water like a sponge causing the glue to let go, the filon delaminates from the under structure.

Check your basement and firewall area, that's where some of my rain water settled. Some rolled along the basement frame area , out the back near the dump valves. Water collected at every horizontal area under the kitchen sink, along the outside wall.

****The AF common ground is located between the firewall and the water heater. You can see it in the drivers side corner of the camper if you use a small mirror and flashlight. This rusted and killed all my 12 volt power while on the road.

I connected the generator cable inside my empty generator compartment to restore my common ground to get things working again. It was a temp/perm fix because it worked ,it lasted and saved me from ripping out the water heater to get at that rusted ground.

The rest of the water soaked my mattress completely. I had the pleasure to sell it at a garage sale as a water bed to re-coop some of my lost money.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-03-2014 06:19 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-02-2014 05:30 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-02-2014 01:34 PM

2010 Arctic Fox 1140 DB, 220 watts solar, custom 4 in 1 "U" shaped dinette/couch, baseboard and Cat 3 heat, 2nd dinette TV, cabover headboard storage, 67 TC mods

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-02-2014 12:43 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-02-2014 11:32 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-02-2014 10:57 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-02-2014 08:32 AM

ScottG wrote:

I would remove all the loose sealant in that area and uncover the screws in the trim piece that covers the seam. Make sure they are tight and the wood underneath isn't rotten. You need a mechanical junction to keep that point from opening again. You may even want to add another screw of two to keep this area tight. Then reseal with Dicor self leveling caulk.

Ditto.

Dicor self leveling sealant is what's there already.

If nothing more happened than the sealant lifting, then after it's removed, apply more.

I think AF uses butyl rubber putty under the metal strip, which seals up that area should the Dicor separate, but a thorough inspection is a good idea once you get the Dicor sealant removed.

I would remove ALL of the Dicor sealant at the corner, and apply new. Do the same at the other corner

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-02-2014 08:13 AM