- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- Best Roof Coating

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Best Roof Coating

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-07-2021 06:42 AM

Proguard, Heng's, Kool Seal, and Dicor. I would appreciate comments about any of these from experienced users in order to help make a decision.

Thanks so much!

Mike

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Sep-19-2022 02:10 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-27-2021 06:13 AM

JIMNLIN wrote:

I wouldn't draw any conclusion based on one persons bad experience with any product. Too many variables and in some cases 1000 times more folks have no issues with that product.

Years ago before rubber roof material most rv trailers came with mill finish aluminum roof material like my '84 26' fifth wheel rv trailer. Those old mill finish roofs were hot in the sun. The material came in huge rolls and was oily. This was before white aluminum material became available.

Not much in roof coatings was available back then other than Cool Seal White elastomeric. I applied 3 coats per instructions over the mill finish roof. WE kept the trailer 7 more years and no issues with it. The trailer was much cooler with the white roof. There were no leaks on the roof ...I just wanted a cooler camper and got it.

The oils on the roof material needed special attention for complete removal. I cycled the prep instruction three times. Heavy oils were used in the rolling and crimping mfg process.

Painting a vehicle or applying a roof coating takes special knowledge and mostly experience with prepping the job. The part I always hated.

Cool Seal is one of several products I have tried, each product has failed in one way or another. I also tried the big rage of bedliner of a few yrs back, it too failed and sadly when it failed it damaged the roofing underneath it, causing a tear which then proceeded to leak all winter long ruining my ceiling panels.

As I see it, each product is of dissimilar and incompatible material which has an expansion and contraction ratio that is also not compatible.

In other words, original roof expands/contracts at one rate, the fix in a can expands/contracts at a different rate. The two different rates then will stretch/shrink enough to eventually lead to the weaker material to fail.

The only way to 100% avoid dissimilar expansion/contraction rate is to use 100% the same material as the base OEM material. Oh, you might get close and lucky to find one that is similar enough for a short time but it will eventually fail.

My roof gets 100F more temps in the summer and can get weeks on end at -20F or a bit lower, that is a huge temperature swing and anything that is not compatible with that type of temp swings will fail.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-27-2021 05:56 AM

Years ago before rubber roof material most rv trailers came with mill finish aluminum roof material like my '84 26' fifth wheel rv trailer. Those old mill finish roofs were hot in the sun. The material came in huge rolls and was oily. This was before white aluminum material became available.

Not much in roof coatings was available back then other than Cool Seal White elastomeric. I applied 3 coats per instructions over the mill finish roof. WE kept the trailer 7 more years and no issues with it. The trailer was much cooler with the white roof. There were no leaks on the roof ...I just wanted a cooler camper and got it.

The oils on the roof material needed special attention for complete removal. I cycled the prep instruction three times. Heavy oils were used in the rolling and crimping mfg process.

Painting a vehicle or applying a roof coating takes special knowledge and mostly experience with prepping the job. The part I always hated.

'03 2500 QC Dodge/Cummins HO 3.73 6 speed manual Jacobs Westach

'97 Park Avanue 28' 5er 11200 two slides

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-26-2021 06:49 PM

https://crazyseal.com/advantages/?gclid=CjwKCAjw95yJBhAgEiwAmRrutJItNr3Oli1Y4r36rAp9R8jBgNBdvMEixobP5pW8I8rWMguKeYMKjxoCka4QAvD_BwE

2013 GMC 2500HD Duramax Denali. 2015 CreekSide 20fq w/450 watts solar and 465 amp/hour of batteries. Retired and living the dream!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-21-2021 09:50 AM

BarneyS wrote:

I used the ProGuard product quite a few years ago on my Sunnybrook trailer and again a few years back. At first I was quite happy with it but it has rapidly deteriorated and I am now in the process of scheduling a complete tear off and replacement of the roof covering.

You can see my post from 2012, with pictures, here.

I am afraid I can no longer recommend the use of this product.

Barney

BarneyS, your experience echos my experience with liquid repairs in a can. They look great for a short time and then deteriorate/peal/wear off in a matter of a few yrs after application.

I used a different brand with similar results, looked great for two-three yrs, then it started to wear thin in spots to the point the old roof started showing through. What didn't wear thin started to peal off.

It isn't an issue with the brand of the product or how well you clean/prep the roof. It is more of the fact that with liquid applications the liquid must be thin enough to brush/roll/spray on to the roof. Those layers will never be as thick as the original surface layer the roof had from factory and will require multiple applications to build up multiple thin layers.

It just will not last as long as replacing the roof with a new membrane.

Liquid repairs are fine if you are planning to hide defects of the roof for selling to the next unsuspecting buyer , but if you are planning to keep more than a few yrs replacing the roof is the better route.

Once you start painting the roof, you will have to paint it again and again as the paint wears out.

In hindsight, I should have taken some pix of my roof as the liquid repairs deteriorated to show the forum, it is disheartening to go through the expense, hard work and time just to realize it only gives you a few good years and then you have to do it all over again.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-21-2021 08:53 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Aug-21-2021 04:49 AM

Ride-rite air bags Rancho 9000x

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-23-2021 10:58 AM

You can see my post from 2012, with pictures, here.

I am afraid I can no longer recommend the use of this product.

Barney

Hensley "Arrow" 1400# hitch (Sold)

Not towing now.

Former tow vehicles were 2016 Ram 2500 CTD, 2002 Ford F250, 7.3 PSD, 1997 Ram 2500 5.9 gas engine

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-24-2021 05:06 PM

I don't have a lot on my roof but I will remove the old Dicor that is around the antenna and apply new.

Thanks again for the information. I'd go up on the roof and take some pics but its covered with ash from the forest fires we are having. If it clears up I will do it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-24-2021 12:20 PM

qtla9111 wrote:

Great write up John. Truly appreciated. I am wanting to use the Eternabond on the edges and other areas as you show in the picture.

On the roof accessories, is it necessary to use Dicor first and then later follow up with Eternabond or can I just put the Eternabond over the cleaned area?

Thanks again.

Your welcome and glad it helped.

A heads up on using Eternabond and Dicor under the eternabond (Ebond). Dicor gases off as it cures, and that gassing off period can be 2 to 3 weeks pending drying conditions. If you apply Ebond over uncured Dicor, the gassing off will create bubbles in the Ebond.

I wait 3 to 4 weeks for the gassing off and then Ebond. Longer is OK, just not shorter.

I'm note sure what context you are asking about

On the roof accessories, is it necessary to use Dicor first and then later follow up with Eternabond

I do not know the condition of your existing Dicor, or how old it has been on. Pictures really help in these cases. If Dicor is heavily cracked and crumbled, in my mind it shot. In that case, I would use a heat gun and all edges dulled putty knife and clean off the bad Dicor down to clean Dicor or none left, put new Dicor on, let it gas off, then Ebond. This gives you double sealing.

Also about cleaning, Ebond or even more Dicor, will not properly adhere to dirt filled old Dicor or roofing. If you have sound, old and dirt imbedded caulk, or the roof, it has to be totally cleaned before applying new Dicor or Ebond. Most times, soap and water will not clean heavy dirted up Dicor. For EPDM roofing, you need to use mineral spirts on a rag, clean with it, wipe it off as soon as it is clean, then follow with a high evaporating off cleaner wiped on a rag to take the oily reside left over by the mineral spirits. Do not let the mineral sprits soak on the caulk on rubber. I use Naphtha as my high evaporating off cleaner. Etneraclean works and some use denatured alcohol as the high evaporative cleaner. Technically denatured alcohol is not rated as a cleaner, it is stove fuel, but they still use it.

If that does not answer your question, explain more what your mean.

Hope this helps.

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-24-2021 11:54 AM

On the roof accessories, is it necessary to use Dicor first and then later follow up with Eternabond or can I just put the Eternabond over the cleaned area?

Thanks again.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-24-2021 08:07 AM

qtla9111 wrote:JBarca wrote:TECMike wrote:

And I also should have used 303 Protectant on mine through the years. Your roof is a testimony to that product.

I never knew how much the 303 really does for the good of the caulk and the rubber, by cleaning the roof correctly and using the 303, until I saw it with my own eyes, on the same age roofing system, that is not washed, and not cared for on the caulk.

John

John,

Could you share your process for cleaning the roof correctly?

Thanks

Hi,

Here is the process I use on Dicor EPDM Brite Ply roofing. In my case I do not have a walk on roof so I do this from the side of the camper. I would do it from the side even if I had a walk on roof. The roof is too slippery when wet. The key for cleaning is, you want to remove the dirt but not over scrub to take off the white shed layer. Mold is cleaned differently and is not dirt, one needs to learn what is mold and what is dirt. If the detergent did not touch it, odds are high, it's mold.

1. Rinse roof with hose sprayer to rinse off loose dirt and fully wet the work area.

2. Using laundry detergent (I use Tide) water mixture and a "soft" car wash brush on a pole, wash the roof like you do your high end sports car. All this is trying to do it get the dirt as that is all the detergent will take off.

3. I clean the inside of the gutter rail with a tooth brush. The dirt/dust buildup can be bad in there and the dirt slows down water draining from the gutter.

4. Rinse the work area well. Move ladder down to the next work area and repeat. Rinse side of camper as you move from the stuff that flows off as you go. Do not let it dry on.

5. I can only reach a little past half way across the camper, so I need to go down both sides to do the total roof. The work area is about 4 1/2 ft across the 8 ft wide roof, and about 6 feet down the length of the camper for each ladder setting.

If you live in an area, the midwest or northeast, where mold grows, (in Ohio it grows fast) I do a mold clean on the roof every so often. This removes the black specs that can look like dirt. This is separate from the detergent washing.

Mold kill process. This is not done after every wash, only when needed. For Ohio and camper living outside, this may be once a year, maybe twice for heavy mold growing times.

6. After the detergent cleaning is over, and the conditions of day are right, I start the mold kill process. You want to avoid the high sun, high temperature and a high wind part of the day. Everything evaporates too fast in those conditions. The ideal condition is a cloudy day with low, to no wind, temps below 78 F ish. Early morning or later after dinner in the summer can work.

7. Hose wet the work area you are working on.

8. Using a non scented standard bleach and water solution in a 5 gallon bucket. (I use 2 gal water to 1/2 to 3/4 cup of fresh bleach to do a 32 ft camper) Spread the mixture on the roof with the car wash brush and you want it on wet. Do "not" scrub, scrubbing will not help, just brush it on, good and wet. And let it sit and soak for 10 to, most times no more then 15 minutes. Rewet it with solution if it starts drying during this time. You do not want it to dry onto the roof intentionally. The bleach needs time to work.

9. Before leaving that work area to go to the next, rinse the sides of the camper well for any bleach solution that runs down the side of the camper.

10. Move to the next work area and repeat the above. Ideally you can get the whole camper at once before it starts drying. But if you can't, then just do the left and right side and half the camper at once or what ever length you can do. You just do not want to rinse off the treated area until it has had time to do the mold kill work.

11. After the mold kill time is up, rinse the area well and the sides of the camper again. If there are some areas still not killed, repeat those areas. The roof will come back white.

12. Treat roof with 303 after it has dried after every cleaning/mold kill.

Notes:

Do not over scrub, that is what can take off excess white shed layer on the EPDM.

If the camper lives outside, 3 to 4 cleanings a year helps keep the dirt in check and build up bonded to the roof. The dirt comes off a lot easier, especially with the 303 on the roof. If the camper is stored inside, then about 2 cleanings per year.

If you have not done a cleaning in a few years, you most likely need to do 2 detergent washes, sometimes 3. You may even need to use a different cleaner if 2 washes with Tide do not remove the bonded on dirt buildup. On my project camper that have not been cleaned in many years, (some 10 years), 2 to 3 detergent washes plus a different detergent is really needed before the mold kill is common to bring the roof back to life. I have pics of that if wanted.

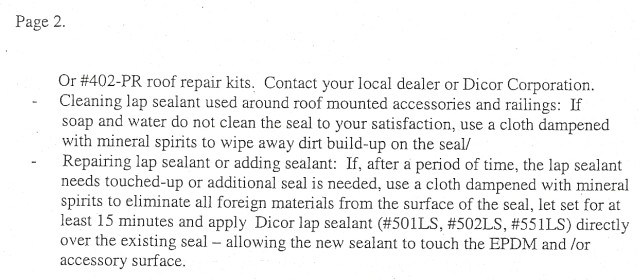

I really did not invent this process, maybe embellished it. Below is what came in my owners manual from Dicor in 2003. They state full strength bleach is OK, but I would never do that due to the decals on the camper.

A few pics from the process.

Directions that came in my manual.

This does take time. The bigger the camper, the longer the time.

Hope this helps

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-24-2021 05:30 AM

JBarca wrote:TECMike wrote:

And I also should have used 303 Protectant on mine through the years. Your roof is a testimony to that product.

I never knew how much the 303 really does for the good of the caulk and the rubber, by cleaning the roof correctly and using the 303, until I saw it with my own eyes, on the same age roofing system, that is not washed, and not cared for on the caulk.

John

John,

Could you share your process for cleaning the roof correctly?

Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-24-2021 01:57 AM

We now have a 37' fiver and the roof, in good shape was tan. I used the same Dicor for the EPDM roof but this time used Cool Beads Dicor and painted it White. Reduced inside temp by 15 degrees. Great product along with dicor sealant that I used when mounting 6 solar panels.

2015 F250 4x4 6.2L 6 spd 3.73s, CC Short Bed, Pullrite Slide 2700, 648 Wts Solar, 4 T-125s, 2000 Watt Xantrax Inverter, Trimetric 2030 Meter, LED Lights, Hawkings Smart Repeater, Wilson Extreme Cellular Repeater, Beer, Ribs, Smoker