- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- Re: Question about Battery Load / Inverter Capacit...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Question about Battery Load / Inverter Capacity

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-22-2016 03:30 PM

I'm almost embarrassed to ask this, because I've read so many articles, posts about the topic - but I STILL can't figure it out. Here is my scenario :

I have (2) 12v AGM batteries wired in Parallel. I have 4 gauge wires coming off of one of the batteries, about 9 feet, to an inverter. First, I was using a PowerBright 1500W (3000 peak) inverter. I tried to run a Keurig Mini (1350W requirement) and then a very small heating device (1200W requirement) Both of them "tripped" the inverter and wouldn't. I wasn't totally shocked - especially with the Keurig, I know that the startup time to heat the water may exceed even their "peak" limits since it goes longer than a few seconds.

After talking to someone on the phone from PowerBright, they said that the inverter wouldn't handle the Keurig, but that the 2300W model would definitely handle it. So I purchased one of those. Same problem.

I've checked all of the obvious things (the Keurig definitely works, all connections are tightly connected, and the inverter DOES work for other devices, with smaller wattage requirements)

This leads me to what I'm wondering/thinking. Is it POSSIBLE, that my BATTERY BANK is what is limiting the running of the Keurig? I can't seem to find a simple equation or explanation as to how to calculate what load the inverter can handle. Meaning.... I *think* that even though the inverter can handle 2300 Watts - if the battery bank can't handle it... it doesn't matter what size inverter you have. I would think that 2 AGM (34M) Interstate batteries could handle a minute at 1350 watts draw...but perhaps not, as this is the only factor that I can't seem to clarify and would certainly explain why neither inverter worked!!

I'm hoping someone here with good experience/knowledge can please enlighten me. I'm not sure how else to test without adding more batteries (and I'm not even sure that's a logical solution). Thanks in advance for any help you can provide!

Thank you,

Tom

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-23-2016 06:44 PM

SoundGuy wrote:Just trying to stay focused on the OP.

Not sure where we disagree. :h Clearly the OP is using cable that's too long and of insufficient gauge for the load he's intending to power, not to mention he's attempting to run these heavy loads with just 2 AGM battery of unknown capacity. Doesn't make a lot of sense to me and now he's asking why it doesn't work? :R

You called out my quote from the manual and seemed to imply it can be ignored or there is a better system(blue sea) or if big wire is too much $$ just install what is affordable.

A simple "+1" is fine if we agree. Or just state your thoughts independently.

Sometimes messages just get crossed up a bit on the internet.

Cheers 😉

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-23-2016 11:18 AM

SoundGuy wrote:smkettner wrote:

Cable Gauges

When connecting the inverter to a battery bank use the thickest stranded

insulated copper wire available in the shortest length practical. If the inverter &

the battery are positioned within 4 FT of each other, a minimum of #4 gauge

wire should be used to make the connections. When the distance between

inverter & battery bank is 4-6 FT, a minimum of #2 gauge wire is required.SoundGuy wrote:

For the OP's application I'd agree cable gauge he's used is insufficient and cable length too long but I'm not sure I'd agree with this as a generalized statement. When I wired in my own 1000 watt inverter I could only find at reasonable cost 4 gauge wire so that's what I used. My intention was to have each cable no longer than 4' but because I wanted to protect the inverter from the elements by locating it in the trailer's front pass through storage compartment the runs from the battery to the inverter ended up being 6'. However, according to this Blue Sea DC Wire Gauge Chart I'm well within spec for up to a 100 amp draw. Typically though I wouldn't draw any more than 70 amps at most so although I had considered replacing those 4 gauge cables with something heavier I'm thinking now that I'll just leave it as is. I wouldn't doubt however that root cause of the OP's problem is that he's used cable that's too long and of insufficient gauge, especially when just 2 batteries of unstated capacity are most likely marginal for such a high draw application.smkettner wrote:

Yes you can engineer for the minimum and then use just half capacity and get by fine.

The manual I quoted is for the OP's inverter and should include not only running at max rating but also to consider getting full surge performance.

The OP is using the inverter near max. No reason to shortcut the OEM install instructions.

Not sure where we disagree. :h Clearly the OP is using cable that's too long and of insufficient gauge for the load he's intending to power, not to mention he's attempting to run these heavy loads with just 2 AGM battery of unknown capacity. Doesn't make a lot of sense to me and now he's asking why it doesn't work? :R

I'll never understand people that have to be insulting in their "responses". However, if it makes you feel superior to question the intelligence of sincere questions in these forums, have at it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-23-2016 11:06 AM

smkettner wrote:

Cable Gauges

When connecting the inverter to a battery bank use the thickest stranded

insulated copper wire available in the shortest length practical. If the inverter &

the battery are positioned within 4 FT of each other, a minimum of #4 gauge

wire should be used to make the connections. When the distance between

inverter & battery bank is 4-6 FT, a minimum of #2 gauge wire is required.

SoundGuy wrote:

For the OP's application I'd agree cable gauge he's used is insufficient and cable length too long but I'm not sure I'd agree with this as a generalized statement. When I wired in my own 1000 watt inverter I could only find at reasonable cost 4 gauge wire so that's what I used. My intention was to have each cable no longer than 4' but because I wanted to protect the inverter from the elements by locating it in the trailer's front pass through storage compartment the runs from the battery to the inverter ended up being 6'. However, according to this Blue Sea DC Wire Gauge Chart I'm well within spec for up to a 100 amp draw. Typically though I wouldn't draw any more than 70 amps at most so although I had considered replacing those 4 gauge cables with something heavier I'm thinking now that I'll just leave it as is. I wouldn't doubt however that root cause of the OP's problem is that he's used cable that's too long and of insufficient gauge, especially when just 2 batteries of unstated capacity are most likely marginal for such a high draw application.

smkettner wrote:

Yes you can engineer for the minimum and then use just half capacity and get by fine.

The manual I quoted is for the OP's inverter and should include not only running at max rating but also to consider getting full surge performance.

The OP is using the inverter near max. No reason to shortcut the OEM install instructions.

Not sure where we disagree. :h Clearly the OP is using cable that's too long and of insufficient gauge for the load he's intending to power, not to mention he's attempting to run these heavy loads with just 2 AGM battery of unknown capacity. Doesn't make a lot of sense to me and now he's asking why it doesn't work? :R

2014 Coachmen Freedom Express 192RBS

2003 Fleetwood Yuma * 2008 K-Z Spree 240BH-LX

2007 TrailCruiser C21RBH * 2000 Fleetwood Santa Fe

1998 Jayco 10UD * 1969 Coleman CT380

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-23-2016 07:49 AM

SoundGuy wrote:smkettner wrote:

Cable Gauges

When connecting the inverter to a battery bank use the thickest stranded

insulated copper wire available in the shortest length practical. If the inverter &

the battery are positioned within 4 FT of each other, a minimum of #4 gauge

wire should be used to make the connections. When the distance between

inverter & battery bank is 4-6 FT, a minimum of #2 gauge wire is required.

For the OP's application I'd agree cable gauge he's used is insufficient and cable length too long but I'm not sure I'd agree with this as a generalized statement. When I wired in my own 1000 watt inverter I could only find at reasonable cost 4 gauge wire so that's what I used. My intention was to have each cable no longer than 4' but because I wanted to protect the inverter from the elements by locating it in the trailer's front pass through storage compartment the runs from the battery to the inverter ended up being 6'. However, according to this Blue Sea DC Wire Gauge Chart I'm well within spec for up to a 100 amp draw. Typically though I wouldn't draw any more than 70 amps at most so although I had considered replacing those 4 gauge cables with something heavier I'm thinking now that I'll just leave it as is. I wouldn't doubt however that root cause of the OP's problem is that he's used cable that's too long and of insufficient gauge, especially when just 2 batteries of unstated capacity are most likely marginal for such a high draw application.

Yes you can engineer for the minimum and then use just half capacity and get by fine.

The manual I quoted is for the OP's inverter and should include not only running at max rating but also to consider getting full surge performance.

The OP is using the inverter near max. No reason to shortcut the OEM install instructions.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-23-2016 07:41 AM

tfirma wrote:

While a larger capacity inverter would certainly come in handy when I'm boondocking, I suppose there are other ways to make coffee, etc. without trying to jump through so many hoops.

Well there's certainly no need to use a Keurig Mini that draws a whopping 1350 watts just to make coffee. :E We've been using this 4-cup Cuisinart Coffee Maker I bought at Sears which is rated at 550 watts and measures an actual 505 watts when powered by my 1000 watt PSW inverter. You also mentioned in your original post a "very small heating device" that requires 1200 watts but I'm trying to imagine what "heating device" would be worth running when you don't have shore power? :h

2014 Coachmen Freedom Express 192RBS

2003 Fleetwood Yuma * 2008 K-Z Spree 240BH-LX

2007 TrailCruiser C21RBH * 2000 Fleetwood Santa Fe

1998 Jayco 10UD * 1969 Coleman CT380

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-23-2016 06:32 AM

pianotuna wrote:

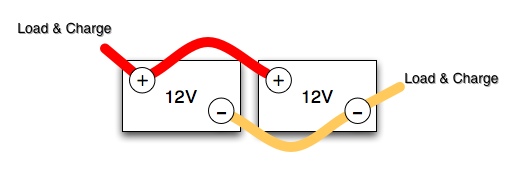

This is what is balanced and best for twin twelve volt batteries.

As it often doesn't cost a dime more to do this, I think it is worth the trouble.

The inverter is too far from the battery bank and the wire is too small.

Little things snowball when you have low voltages & high amperages. Make sure the jumpers between the batteries are as large as the main cables.

I would recommend a battery bank of at least 4 6 volt golf cart batteries for successful inverter use. More if you plan to do longer heating loads.

2016 Toyota Tundra SR5 TRD Double Cab

2004 Starcraft 11RT (Replaced by)

2011 Eclipse Milan 18CK Travel Trailer

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-23-2016 06:07 AM

Thank you to everyone, again, for your input and thoughtful comments!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-23-2016 03:18 AM

smkettner wrote:

Cable Gauges

When connecting the inverter to a battery bank use the thickest stranded

insulated copper wire available in the shortest length practical. If the inverter &

the battery are positioned within 4 FT of each other, a minimum of #4 gauge

wire should be used to make the connections. When the distance between

inverter & battery bank is 4-6 FT, a minimum of #2 gauge wire is required.

For the OP's application I'd agree cable gauge he's used is insufficient and cable length too long but I'm not sure I'd agree with this as a generalized statement. When I wired in my own 1000 watt inverter I could only find at reasonable cost 4 gauge wire so that's what I used. My intention was to have each cable no longer than 4' but because I wanted to protect the inverter from the elements by locating it in the trailer's front pass through storage compartment the runs from the battery to the inverter ended up being 6'. However, according to this Blue Sea DC Wire Gauge Chart I'm well within spec for up to a 100 amp draw. Typically though I wouldn't draw any more than 70 amps at most so although I had considered replacing those 4 gauge cables with something heavier I'm thinking now that I'll just leave it as is. I wouldn't doubt however that root cause of the OP's problem is that he's used cable that's too long and of insufficient gauge, especially when just 2 batteries of unstated capacity are most likely marginal for such a high draw application.

2014 Coachmen Freedom Express 192RBS

2003 Fleetwood Yuma * 2008 K-Z Spree 240BH-LX

2007 TrailCruiser C21RBH * 2000 Fleetwood Santa Fe

1998 Jayco 10UD * 1969 Coleman CT380

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-22-2016 08:15 PM

When connecting the inverter to a battery bank use the thickest stranded

insulated copper wire available in the shortest length practical. If the inverter &

the battery are positioned within 4 FT of each other, a minimum of #4 gauge

wire should be used to make the connections. When the distance between

inverter & battery bank is 4-6 FT, a minimum of #2 gauge wire is required.

Owner's guide

You have twice the distance and half the wire.

http://www.donrowe.com/product-p/awg30-10.htm

The AGM helps and still you really need another battery or two.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-22-2016 08:04 PM

As it often doesn't cost a dime more to do this, I think it is worth the trouble.

The inverter is too far from the battery bank and the wire is too small.

My ride is a 28 foot Class C, 256 watts solar, 556 amp-hours of Telcom jars, 3000 watt Magnum hybrid inverter, Sola Basic Autoformer, Microair Easy Start.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-22-2016 07:05 PM

If you do rewire the inverter and leave it in the same location, a 135A draw may draw down your 12V AGM batteries below the inverter's threshold.

'71 Starcraft Wanderstar -- The Cowboy/Hilton

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-22-2016 06:43 PM

The wiring is wrong. Only one wire should come from each battery, one from pos post and the other wire from neg post of the other battery.

Why is the inverter 9 feet from the battery bank?

HTH;

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-22-2016 04:24 PM

in the AC world... large startup is common in power devices.. as its only 5 to 10 seconds... could be 3 times the running watts.

or

your battery bank is dropping voltage at the startup...

volt meter at inverter to see..

then volt meter at battery bank..

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-22-2016 04:12 PM