- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- Re: X-chock vs. Jack Stabilizers

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

X-chock vs. Jack Stabilizers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-28-2014 07:15 PM

X-chock

Jack Stabilizer

Thanks,

Nathan

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-01-2014 01:48 AM

gregrc75 wrote:

Larry-

I usually use x-chocks, stabilizers, and a pair of jack stands in the middle of my travel trailer when set up. I still experience a decent amount of movement with these in place. I have been reading this thread since it started a few days ago. So, curiosity got to me this afternoon. Since the snow had melted and it was a warm 40 degrees, I pulled out my jack stands and tried the method you described. I have to say, just with those 4 jack stands in place, it is way more solid than any other time I have set it up. I See what you are saying that a rear living room floor plan may have a bit more wiggle so I am thinking of using that Valterra stabilizer across the back bumper to help eliminate the back end bounce/wobble. Using that, and installing my x chocks, I think I will be very pleased. Thanks for you suggestion.

You are very welcome and glad to help and again I doubt anything except the "mobile home cinder block system" is going to be 100% effective, 100% of the time. However, having used this portable screw jack stand system for over 20 years and been completely happy I was appalled at what was included on our current 2007 Trailer and fortunately I had kept the old stands from 1981 which I'm still using to this day. It's being able to help folks like you that are adventurous to step out of the box that makes me endure some of the skepticism sometimes when I suggest these NON STANDARD things. I can't comment on all these wheel chock devices since I'm a plastic ramp sort of person and just like to keep it as simple as possible for the most part. I completely removed all my OEM stab jacks (BTW I then shaved over 50lbs from my TT weight in the process) so I don't even have one at the very end of the trailer, but that works for us and as I said being able to do w/o that set at the very end is going I think be very dependent on the exact TT, floorplan and how you use it. A lot of TT's have a bunkhouse back there and if you have little ones I can see where you're going to need that extra support.

One other suggestion is you might need some experimenting in finding the best placement and especially using that set of jacks at the end and how you tension them using the tongue jack. IMO you're never going to get enough support with these screw type scissors jacks by just using the screw part, but to be honest I haven't needed to experiment much with that issue. A real bonus is that I found the front jack stand placement just happened to be close to the door so the movement from going in and out was virtually eliminated when I put my jackstand in that general area around the door opening.

Again it is ABSOLUTELY CRITICAL that you get sufficient weight transferred to those jackstands and the only way I know is to use the tongue jack with the tongue up tongue down routine ... trying it with just the screw isn't going to cut it.

I'm a die hard believer in trying to keep things simple under the trailer from a maintenance point since I had our last trailer for over 20 years and know what time and long term exposure to that harsh environment will do to things. I try my best to make sure anything under the trailer if possible uses things like SS, aluminum, brass, rubber, nylon bolts/nuts, etc. so things like rust and corrosion is minimized. One of the first things I did was to replace all the sheet metal screws that held up my coroplast underbelly to the frame rails with nylon bolts and washers so I had a hope of removing them at sometime in the future if that was every necessary.

Larry

RAINKAP INSTALL////ETERNABOND INSTALL

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 06:00 PM

I usually use x-chocks, stabilizers, and a pair of jack stands in the middle of my travel trailer when set up. I still experience a decent amount of movement with these in place. I have been reading this thread since it started a few days ago. So, curiosity got to me this afternoon. Since the snow had melted and it was a warm 40 degrees, I pulled out my jack stands and tried the method you described. I have to say, just with those 4 jack stands in place, it is way more solid than any other time I have set it up. I See what you are saying that a rear living room floor plan may have a bit more wiggle so I am thinking of using that Valterra stabilizer across the back bumper to help eliminate the back end bounce/wobble. Using that, and installing my x chocks, I think I will be very pleased. Thanks for you suggestion.

Ben - Yellow Lab. Charley - Red Lab

2018 Keystone Bullet Premier 30RIPR

2016 Nissan Titan XD SL 5.0

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 03:50 PM

LarryJM wrote:

1.

2. While you haven't faced any maintenance issues you have a 2014 basically BRAND NEW TRAILER. Come back in 5 or 10 years and will talk about how well those nuts and scissor jacks and even the stab bars have held up after the exposure to the type of environment I previously described and that was my point.

3. I don't see how you can get any sort of crank on those two rear most stab bars with that bolt head facing the ground like a foot away. It seems one is going to have to lay down physically and get under the trailer with a wrench or something to tighen and loosen those two bolts. If you do it another way then that would be a good hint to share with others since even the JT strong arms with the hand screws still has from my view that access issue.

4. Lastly I have never said or meant to imply that the stab bars don't help only that IMO for the previous reasons I have stated are working on the less important sources of the stability problem and are what I call bandaids in that they are basically fixing an issue that again IMO can be avoided for the most part to begin with and that is what type of jacks are being used and where they are generally located.

Larry

This isn't my first TT. My last one was bought new in 1990. I gave it away in September and bought this one. I believe I learned a thing or two with my last camper. As I mentioned before, but you apparently didn't read, I still have the aluminum screw jacks that came with my old TT.

You don't see how I can reach the lock nut on the strong arms without laying on the ground, which reveals a fundamental difference between us. I have, and have used, the screw jacks, and based on my experience, have opted for the permanently installed jacks with strong arms which, BTW, are no more than 6 inches in from the edges of the camper. The rods of the arms rotate freely and easily.

Perhaps you should come back in a few years when you have tried something new and can speak from actual experience.

2023 Ram 6.7L Laramie Mega Cab

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 02:20 PM

Nfrank wrote:

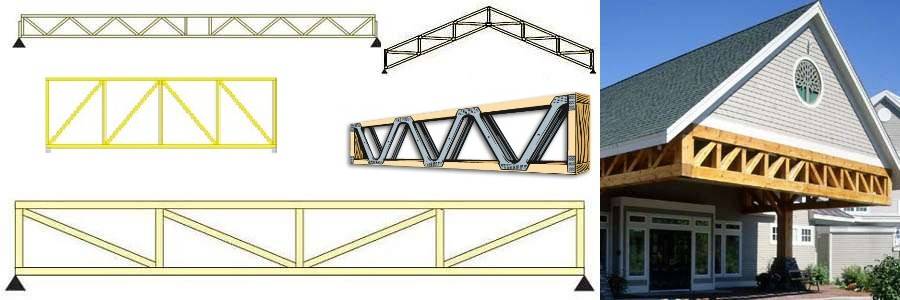

Larry, Thanks for your input. I'm definitely considering your idea, especially since it's so cheap. The problem with the scissor jacks is that it supports the frame in a parallelogram shape. That shape is inherently prone to swinging around. The product your describing will be a better post, but it'll still just be still a single post holding the trailer frame in only one position. I have to believe that the trailer will be more rigid with the bars holding the trailer in another connection point in that I'm sure the frame shown here is better with the diagonals than without.

You are correct, BUT .... the most important thing is that if you add the stab bars to the existing system you are fixing the support where it is MUCH, MUCH less effective than if you were to move it closer to the axles and even more importantly fine tune where you want the actual support based on some experimentation. As I previously said I didn't or mean to imply that adding these "EXTRAS" didn't fix the issue of movement of the scissors jacks and that will obviously help. My point was that support at the corners is in the WRONG LOCATION to begin with and doesn't effectively address the two MAJOR SOURCES of the "ROCK-N-ROLL" issue. This "SUPPORT LOCATION" issue is why many folks report HUGE IMPROVEMENTS if they simply put another of these less effective scissors type supports closer to the axles and IMO generally that is in front because I think interference issues in the rear generally due to sewer connections, etc.

Just remember there is an optimum placement for what I'm advocating and you have to get "SIGNIFICANT" support on them or even these won't be effective is addressing the two "MAJOR SOURCES" I have previously described.

If you want to test out my concept you could even "experiment" w/o even buying those screw type jack stands. Just use something solid to support the frame at the locations closer to the axles like Lynx Levelers, car type jack stands, blocks of wood, etc. Now blocks of wood and the levelers will give even better results than even the screw type jackstands and are approaching the often quoted "cinder block" ROCK SOLID system used in mobile homes.

Larry

RAINKAP INSTALL////ETERNABOND INSTALL

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 11:04 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 10:29 AM

2013 StarCraft Autumn Ridge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 10:09 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 09:27 AM

LarryJM wrote:Larry.wrvond wrote:

Larry,

FIrst, I'd like to let you know I took no offense at your post. You should, however, get a job coaching those people on the television commercials that make the simplest things look impossible to accomplish without whatever product is being hawked. 😉

Second, those scissor jacks are flimsy. They are also what came on the camper. I do own a set of jacks like you describe. They came with my first camper, which did not have scissor jacks. I used them at first, but they have their own set of drawbacks, which I'll not go into here, as I see this as a discussion rather than a debate. Anyway, I went to the junk yard and purchased four scissor jacks from wrecked cars and installed on my camper, which I always thought worked quite well.

As I said, this camper came with the scissor jacks. I would have preferred the newer single leg angular jacks (don't know what they're called), but I got what I got. They came with a socket on the end of a long handle that I use to crank them up and down with. Works really well and doesn't require batteries. The locking nuts on the strong arms are the same size and use the same wrench. Also, those nuts won't fall out. They do not have to be tightened when in the stowed position. They also do not require any special cleaning or lubrication. When I clean the undercarriage of the camper, they are right there and easily sprayed off. They take all of 5 minutes or less to deploy, do a great job of stabilizing my camper, and I like 'em.

1. My battery and other comments about the electric screwdriver is one of the often main arguments on how convenient deploying the stab jacks are and you can obviously do it manually with the crank like you have chosen to do. Almost every thread about stab jacks tauts how great of an idea it is to use the electric drill/screw driver with an extension to raise lower the stab jacks and with your trailer being so new maybe you haven't gotten to that point of going that way, but many, many others have.

2. While you haven't faced any maintenance issues you have a 2014 basically BRAND NEW TRAILER. Come back in 5 or 10 years and will talk about how well those nuts and scissor jacks and even the stab bars have held up after the exposure to the type of environment I previously described and that was my point.

3. I don't see how you can get any sort of crank on those two rear most stab bars with that bolt head facing the ground like a foot away. It seems one is going to have to lay down physically and get under the trailer with a wrench or something to tighen and loosen those two bolts. If you do it another way then that would be a good hint to share with others since even the JT strong arms with the hand screws still has from my view that access issue.

4. Lastly I have never said or meant to imply that the stab bars don't help only that IMO for the previous reasons I have stated are working on the less important sources of the stability problem and are what I call bandaids in that they are basically fixing an issue that again IMO can be avoided for the most part to begin with and that is what type of jacks are being used and where they are generally located.

O.K I think I'm bascially thru here since I don't want to get this too far off topic, but I have my opinion and see many issues with the scissor jack and the stab bar system which I feel are not there with what I have recommended and both are not more of a hassle to use than the other when all things are considered which is often the stated reason why one doesn't like what I am advocating to try. I also contend that my system is CHEAPER, REQUIRES LESS MAINTENANCE, SIMPLIER, and JUST AS OR MORE EFFECTIVE. These forums are IMO for discussing and providing information so the reader can make informed decisions and that is all I'm trying to do.

Larry

The OP had a question.

"X chocks or jack stabilizers, which is the most effective?"

Maybe I missed it in lord knows how many pages of lecturing on other things...

But do you have a opinion on the OPs question?

100% boondocking

2021 Grand Design Momentum 398M

2 bathrooms, no waiting

104 gal grey, 104 black,158 fresh

FullBodyPaint, 3,8Kaxles, DiscBrakes

17.5LRH commercial tires

1860watts solar,800 AH Battleborn batterys

2020 Silverado HighCountry CC DA 4X4 DRW

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 07:14 AM

wrvond wrote:

Larry,

FIrst, I'd like to let you know I took no offense at your post. You should, however, get a job coaching those people on the television commercials that make the simplest things look impossible to accomplish without whatever product is being hawked. 😉

Second, those scissor jacks are flimsy. They are also what came on the camper. I do own a set of jacks like you describe. They came with my first camper, which did not have scissor jacks. I used them at first, but they have their own set of drawbacks, which I'll not go into here, as I see this as a discussion rather than a debate. Anyway, I went to the junk yard and purchased four scissor jacks from wrecked cars and installed on my camper, which I always thought worked quite well.

As I said, this camper came with the scissor jacks. I would have preferred the newer single leg angular jacks (don't know what they're called), but I got what I got. They came with a socket on the end of a long handle that I use to crank them up and down with. Works really well and doesn't require batteries. The locking nuts on the strong arms are the same size and use the same wrench. Also, those nuts won't fall out. They do not have to be tightened when in the stowed position. They also do not require any special cleaning or lubrication. When I clean the undercarriage of the camper, they are right there and easily sprayed off. They take all of 5 minutes or less to deploy, do a great job of stabilizing my camper, and I like 'em.

1. My battery and other comments about the electric screwdriver is one of the often main arguments on how convenient deploying the stab jacks are and you can obviously do it manually with the crank like you have chosen to do. Almost every thread about stab jacks tauts how great of an idea it is to use the electric drill/screw driver with an extension to raise lower the stab jacks and with your trailer being so new maybe you haven't gotten to that point of going that way, but many, many others have.

2. While you haven't faced any maintenance issues you have a 2014 basically BRAND NEW TRAILER. Come back in 5 or 10 years and will talk about how well those nuts and scissor jacks and even the stab bars have held up after the exposure to the type of environment I previously described and that was my point.

3. I don't see how you can get any sort of crank on those two rear most stab bars with that bolt head facing the ground like a foot away. It seems one is going to have to lay down physically and get under the trailer with a wrench or something to tighen and loosen those two bolts. If you do it another way then that would be a good hint to share with others since even the JT strong arms with the hand screws still has from my view that access issue.

4. Lastly I have never said or meant to imply that the stab bars don't help only that IMO for the previous reasons I have stated are working on the less important sources of the stability problem and are what I call bandaids in that they are basically fixing an issue that again IMO can be avoided for the most part to begin with and that is what type of jacks are being used and where they are generally located.

O.K I think I'm bascially thru here since I don't want to get this too far off topic, but I have my opinion and see many issues with the scissor jack and the stab bar system which I feel are not there with what I have recommended and both are not more of a hassle to use than the other when all things are considered which is often the stated reason why one doesn't like what I am advocating to try. I also contend that my system is CHEAPER, REQUIRES LESS MAINTENANCE, SIMPLIER, and JUST AS OR MORE EFFECTIVE. These forums are IMO for discussing and providing information so the reader can make informed decisions and that is all I'm trying to do.

Larry

RAINKAP INSTALL////ETERNABOND INSTALL

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 06:53 AM

Lantley wrote:

Larry JT Strong Arms are available for TT's as well.

JT's for TT's

I do have JT's on the front and rear of my fiver.

Jt's provide a real stability solution.

Thanks and I knew JTs can also be used on TTs and I'm not and haven't said they won't help, it's just IMO the are still what I call a bandaid and a major argument against what I'm advocating and those with the scissor jacks is the hassle of having to get down and put the screw jack stands under the trailer, but to fix the poor stab jack design one has to get down even further under the trailer TWICE with Stab bar supports to tighten either one or two of the screws that hold the arms in their extended position and again to loosen the screw to retract the jacks. Thus the argument about having to knee down and even crawl up under the trailer is more of an issue if one has the scissor type stab jacks and have installed the additional stabilizer bars.

Larry

RAINKAP INSTALL////ETERNABOND INSTALL

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 04:07 AM

FIrst, I'd like to let you know I took no offense at your post. You should, however, get a job coaching those people on the television commercials that make the simplest things look impossible to accomplish without whatever product is being hawked. 😉

Second, those scissor jacks are flimsy. They are also what came on the camper. I do own a set of jacks like you describe. They came with my first camper, which did not have scissor jacks. I used them at first, but they have their own set of drawbacks, which I'll not go into here, as I see this as a discussion rather than a debate. Anyway, I went to the junk yard and purchased four scissor jacks from wrecked cars and installed on my camper, which I always thought worked quite well.

As I said, this camper came with the scissor jacks. I would have preferred the newer single leg angular jacks (don't know what they're called), but I got what I got. They came with a socket on the end of a long handle that I use to crank them up and down with. Works really well and doesn't require batteries. The locking nuts on the strong arms are the same size and use the same wrench. Also, those nuts won't fall out. They do not have to be tightened when in the stowed position. They also do not require any special cleaning or lubrication. When I clean the undercarriage of the camper, they are right there and easily sprayed off. They take all of 5 minutes or less to deploy, do a great job of stabilizing my camper, and I like 'em.

2023 Ram 6.7L Laramie Mega Cab

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 03:25 AM

JT's for TT's

I do have JT's on the front and rear of my fiver.

Jt's provide a real stability solution.

r,RV760 w/BC20,Glow Steps, Enduraplas25,Pedego

BakFlip,RVLock,Prog.50A surge ,Hughes autoformer

Porta Bote 8.0 Nissan, Sailun S637

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 02:47 AM

Lantley wrote:

My current rig came equipped with JT Strong arms as stock equipment.

The resolve the stability issue without have to carry,store and handle additional gadgets.

They steady the trailer in both directions unlike the other contraptions. They work!

That is on your 5er and not typical of what is being discussed in this Travel Trailer forum. Those jack stands are more like the screw type I have than the typical scissors type used for most TTs. They don't suffer from the flimsy construction or multiple pivot points that scissor jacks typically have so I'm not sure how well they compare to what is being talked about here. I'm also not sure of what extra considerations there are for 5ers with that extra 8' or so over hang out front and the potentially heavier frames that might be found on 5ers just due from their construction.

Also at least those can be tightened/loosened by hand and don't need extra wrenches, etc.

Finally, I think if those are in the front they have the FULL WEIGHT of the 5er on them much like a tongue jack on a TT since they support the full front part of the 5er when hitching or un hitching. I can definitely see a need for braces on those front supports just from a safety stand point not withstanding a stability consideration.

Do you have the same supports and braces on the rear of your 5er?

Larry

RAINKAP INSTALL////ETERNABOND INSTALL

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 02:25 AM

The resolve the stability issue without have to carry,store and handle additional gadgets.

They steady the trailer in both directions unlike the other contraptions. They work!

r,RV760 w/BC20,Glow Steps, Enduraplas25,Pedego

BakFlip,RVLock,Prog.50A surge ,Hughes autoformer

Porta Bote 8.0 Nissan, Sailun S637

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jan-31-2014 12:50 AM

Since this thread is for you the following post is directed at you and I realize it's going to irritate some folks, but hopefully the arguments, etc. won't get too far out of hand since I will say upfront the following are purely MY OPINIONS and VIEWS and are not subject for discussion, etc. here and now, but I'm not in control of that so I apologize in advance. Also, I admit up front for some scarcasim and drama in some of my statements, but I just couldn't resist in this case so again another apology for those who I will offend.

I about fell out of my seat when I saw the pics posted above by wrvond and they highlight almost all the concerns and illustrate better than words that I have with these as I call them Bandaid fixes and while no body that has spend their hard earned $$$ on these types of things are going to change their mind or admit (that's against basic human nature) what they have now have is even more of a nightmare than what they started with this post of mine is directed only at you since you haven't IMO made any mistakes yet and might make a little more rational vs. emotion decision on what you want to do. Please read the following and be looking at especially the second pic that wrvond posted and consider the following points while looking at that picture.

1. Notice how flimsy those scissor jacks are ... thinly stamped metal, with SIX pivot points PER JACK all of which are going to have play in them or you wouldn't be able to move them. Also note the orientation and how narrow the footprint is front to back of the scissor jacks foot which w/o those stab bars provides almost ZERO resistance to front to back movement. Note the footprint of those screw jack stands I showed in my prior post and decide for yourself which has the better ground to support footprint stability in all planes at the ground contact. You also now have 3 THREADED interfaces to rust/corrode PER JACK that remain under the trailer vs. my ZERO number. Even in the plane perpendicular to that there is still slop/play since the threaded portion of the scissor jack goes thru TWO threaded connections and there has to be clearances in that interface or you wouldn't be able to move the scissor's jack. While my screw jacks stands DO HAVE ONE threaded interface the play in that is basically taken out since it will be under considerable force directly along the axis of the screw since it will be supporting the trailer at the frame.

2. Now look at the entire system in that second pic including those 4 stab bars especially those 4 BOLTS that I assume need to be tightened and loosened each time the scissor jacks are adjusted/retracted/extended to extend or shorten those stab bars ... not to mention lets hope none of those bolts fall out when traveling and that you have spares readily available for replacements. Especially notice that now you not only have to use that ever popular and often mentioned power screwdriver to use on those fancy scissor jacks and find that extension (hopefully you haven't forgotten either and the battery on the power screwdriver isn't dead or you have that ultra light weight spare battery and/or zero weight and zero space taken up battey charger for that power screwdriver battery ... remember the downside of not wanting to waste space for those pesty screw jacks stands of mine) and not only use it but also have either a wrench or socket for those EXTRA TWO BOLTS on the stab bars for each jack. And then folks complain about the extra room and weight that my nesting ALUMINUM Jack stands are, but fail to mention their power screw driver, extensions, wrench/socket for those bolts, battery and maybe the battery charger for that screwdriver. See where I'm going and why I made statements about how folks will defend the basic undefensible when their hard earned $$$$ has already been spent .... VERY FEW will admit their mistakes and especially admit they might have wasted some of that hard earned $$$$. I'm particularly amused when folks don't want to mess with "ALL THAT HASSLE" of bending down and putting my recommended jack stands under the trailer frame, but fail to mention how they are going to instead now be tightening and loosen those TWO stab bar bolts oriented in the plane of the scissors jacks that are now several feet more under the trailer and POINTING DOWN TOWARDS THE GROUND NO LESS being more convenient to tighten/loosen each time you mess with the scissor jacks than HEAVEN FORBID bending down and placing my screw jack stand under the trailer frame ... GASP. That second picture showing how far under the trailer from the bumper and in towards the middle of the trailer inside the frame those end two stab bar bolts are that are now pointing down at the ground and just how one tightens and loosens those up being so much more convenient that placing my one jack stand at that same location ONCE for each setup/tear down. I would assume those bolts would need to be loosened to raise the jacks and then tightened for travel to prevent them working loose and falling out and then loosend to extend and then tighten to secure when you set up. Thus for each move I see the need to get to that bolt and tighten or loosen it 4 TIMES per use. You decide which is easier and more accessible and please go thru your mind setting up the system shown in those pics and storing it and how convenient and what tools are needed and just how much HARDWARE is now now there that will rust/corrode over time vs what I had recommended and how to use it. Please note while you do have to place my jack stands under the frame and hand tighten them up initially that is the ONLY TIME you have to do any bending/adjusting since to remove you just use the tongue jack and like I do my awning rod to pull the jack stands out when removing them which eliminates me even bending down anywhere near them.

Well I think this poor horse is not only dead from all the beating we have inflicted upon it, but is starting to turn to fertilizer from all the pounding and I think I have made the points I wanted to as best as I could and in closing will say do what you want since it's your money ... I look at my job is to give you the best advice and information that I think is out there ... what you do with it is your and yours alone business.

Larry

RAINKAP INSTALL////ETERNABOND INSTALL