- Good Sam Community

- Everything RV

- Technical Issues

- Re: 2kw Inverter + 4 GC2 6v batteries = wiring???

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

2kw Inverter + 4 GC2 6v batteries = wiring???

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 03:00 PM

I have a quantity of 2 AWG wire on a spool, a supply of tin clad copper wire ends in various sizes, and a heavy terminal "hammer spike crimper thing"

I would like to add a battery turn off and shunt to measure amps and also be able to measure voltage/charge remaining.

So here's the setup.

1. Four batteries in a row, long sides against each other. Call them A, B, C, D. A&B pair #1, C&D pair #2

2. Two 2 AWG cables for each section to allow higher amps. Ex. two 2 AWG cables between battery A(-) and B(+), and two 2 AWG cables between battery C(-) and D(+), and two 2 AWG cables between B(-) and C(+) to make two sets of series then paralleled together to get 12v "super battery" LOL

3. Two 2 AWG cables from D(-) to one end of shunt and then two 2 AWG cables from other end of shunt to inverter (switch, then (-)) and PD9270 (-)

4. Two 2 AWG cables from A(+) to inverter (+) and PD9270(+)

5. 120v AC line to distribution box (30 amp transfer switch?) and PD9270

It's a little foggy, so I'll stop there and ask for input 😉

Wire size, wiring diagram, etc.

Caveat, the PS1800 has built in transfer switch, but I prefer not to use it. Want to keep a separate circuit and/or transfer switch at the 30 amp 120v incoming cable for pedestal/generator.

Help? 😉

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 06:07 PM

on Ford E350-460-7.5 Gas EFI

Photo in Profile

2. 1991 Bighorn 9.5ft Truck Camper on 2003 Chev 2500HD 6.0 Gas

See Profile for Electronic set-ups for 1. and 2.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 06:03 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:57 PM

BFL13 wrote:

Is the shunt not for a Trimetric monitor? Read the installation manual--it is quite clear on what goes where. Shunts go on the neg side. BTW you want the 500a shunt for the higher amps the inverter will draw, not the 100a.

The inverter wiring is for the amps you will see. The surge rating is for a very short moment that might happen. The fuse on the pos is supposed to protect the wires in that case, like an ANL fuse will not blow right off, but gives a moment for the surge to go away before it blows but then it will if it stays on.

Others might correct me on that but they would have to explain it, which is ok if they do.

Okay, so I should design the wires for 2kw loads, not 2800 watts?

Not a trimetric, just something cheap and simple 😉

So I should move the shunt to negative side?

I was modeling after Roy's diagram below:

Except for splitting the battery banks 😉

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:46 PM

The inverter wiring is for the amps you will see. The surge rating is for a very short moment that might happen. The fuse on the pos is supposed to protect the wires in that case, like an ANL fuse will not blow right off, but gives a moment for the surge to go away before it blows but then it will if it stays on.

Others might correct me on that but they would have to explain it, which is ok if they do.

on Ford E350-460-7.5 Gas EFI

Photo in Profile

2. 1991 Bighorn 9.5ft Truck Camper on 2003 Chev 2500HD 6.0 Gas

See Profile for Electronic set-ups for 1. and 2.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:41 PM

ampacity isn't the main issue with wire. it is the voltage drop in a 12V system. to much drop and the inverter kicks out thinking battery voltage is low.

2004 14' bikehauler with full living quarters

2015.5 Denali 4x4 CC/SB Duramax/Allison

2004.5 Silverado 4x4 CC/SB Duramax/Allison passed on to our Son!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:38 PM

BFL13 wrote:

That neg from battery to frame needs to be changed to go to the outer end of the shunt along with all the other negs. Only thing from battery neg is one fat (or double thinner) wire(s) to the inner end of the shunt.

I had shunt wired in series in positive line. Is that wrong?

The shunt outer end can't hold all those negs, so you need a neg buss bar to hold a bunch of negs, then a fat wire from the neg buss to the outer end of the shunt.

Still not sure why/where negative goes to the shunt?

Double #2 short wire is huge. Can't see any point in going fatter single. Just have to reduce the ends anyway to fit the inverter and converter terminals. Vector 2000w (4000w surge) inverter specifies a wiring kit of twin #4 three feet long. Twin #2 is way more than that. Holy cow. The inverter is 1800, less than 2000.

Surge capability is 2800 watts. I was designing for that. I'm also wrong on that?

Of course if you have a run of much more than 3 feet distance, say over 6 ft (one way) you would have to go fatter wire.

The inverter is going to have to go into the front storage area, so out of bottom of battery box, under front and up through floor to inverter.

The PD9270 should fit in the box, so it will be closer. I was estimating worst case- if both have to go into the front storage pass through area.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:32 PM

2oldman wrote:

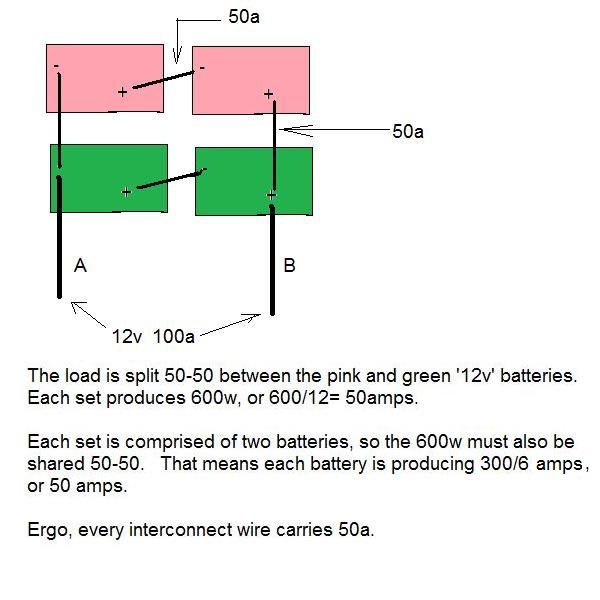

For a 1200w appliance, this is what the approximate amperages to the inverter look like in your setup:

Before we get too involved in this, please share with us what will be the largest loads on your inverter.

Okay, so this is my planned battery wiring diagram.

Each of the 6 wires would be about a foot and would carry up to 100 amps each, correct? They wouldn't have to be doubled, right?

Then the two leads from the center to the right side of the drawing would have to carry 400 amps and would be...doubled 2 AWG (not 2/0), right?

Microwave 13amps is biggest load. I was trying to account for startup surge 😉

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:19 PM

The shunt outer end can't hold all those negs, so you need a neg buss bar to hold a bunch of negs, then a fat wire from the neg buss to the outer end of the shunt.

The PD 70 has two sets of terminals AFAIK. You can use the second set as a buss to connect something else.

Double #2 short wire is huge. Can't see any point in going fatter single. Just have to reduce the ends anyway to fit the inverter and converter terminals. Vector 2000w (4000w surge) inverter specifies a wiring kit of twin #4 three feet long. Twin #2 is way more than that. Holy cow. The inverter is 1800, less than 2000.

My 3000w inverter also has twin terminals and they have a kit for it with double #4 three feet long.

Of course if you have a run of much more than 3 feet distance, say over 6 ft (one way) you would have to go fatter wire.

on Ford E350-460-7.5 Gas EFI

Photo in Profile

2. 1991 Bighorn 9.5ft Truck Camper on 2003 Chev 2500HD 6.0 Gas

See Profile for Electronic set-ups for 1. and 2.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:14 PM

Before we get too involved in this, please share with us what will be the largest loads on your inverter.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 05:11 PM

2oldman wrote:

Sure about what.. the ampacity? I just looked it up. I thought that was why you were doubling up on them. Did I read that right?

I'm a bit out of my area, never really have to spec something this big, so hand-holding is good here 😉

If I add up all my wires, I'll have 6 connections about 1ft each between the four batteries to make them a bank.

Then 2 lengths around 5 ft or so max for the inverter and PD9270.

Is it acceptable to run grounds to Chassis/frame? I saw that in Roy's diagram in another thread.

So are you sure that I can just double up the 1ft lengths between batteries (is this needed, each one would be 100 amps, right?), and then find 4/0 or something for the 5ft lengths?

I'm concerned not with *your* knowledge, but my interpretation of what I *think* you're saying. 😉

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 04:57 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 04:55 PM

2oldman wrote:DiskDoctr wrote:I thought your plan of 2-2awg would be fine. 4/0 is real bear to work with, and is only needed for big draw stuff like extended MW use and maybe coffee makers - which 4 batteries can only handle comfortably for relatively short periods.

So it looks like I need to jump to 4/0 wires?

The ampacity of 2 2awgs is almost the same as 4/0..assuming they work in parallel as you're hoping they will.

Are you sure about this? I have 2 AWG here and ends for it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 04:39 PM

DiskDoctr wrote:I thought your plan of 2-2awg would be fine. 4/0 is real bear to work with, and is only needed for big draw stuff like extended MW use and maybe coffee makers - which 4 batteries can only handle comfortably for relatively short periods.

So it looks like I need to jump to 4/0 wires?

The ampacity of 2 2awgs is almost the same as 4/0..assuming they work in parallel as you're hoping they will.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 04:22 PM

Okay, I'll start sourcing that tomorrow.

Here is the start of a diagram of the wiring I anticipate. Feel free to chop it up and make any corrections 😉

Thanks!

{deleted incorrect diagram, see update later in the thread}

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-06-2017 04:16 PM

time2roll wrote:

IIRC Xantrex recommends 4/0 minimum wire.

http://www.genuinedealz.com/custom-cables?size=46

x2 ... OP mentions 2-4 ft, at worst case, that's 8 feet of cable, plus the lengths of interconnects between batteries. The heavier the better JMHO

Welding cable is cheap if you buy it from a brick 'n mortar welding shop. it's silly expensive online for some reason. I bought 4/0 locally for less than I could get 1 gauge on Amazon.

Super soft high temp silicone (or maybe neoprene?) insulation, ultra fine strands so it is very flexible

2020 RAM 1500, 5.7 4x4, 8 speed

- RV shore power plugged into inverter run by 12v battery and 100w solar panels in DIY Maintenance

- Running A/C over draws the batteries causing inverter alarm in Technical Issues

- Another Kudos to Lippert Tech Support! in Technical Issues

- Solar wiring and other questions in Technical Issues

- 2007 Jayco Greyhawk 33DS Manual in DIY Maintenance