Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- 2005 Dodge Cummins 48RE to G56/Auto to Manual Swap...

Options

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

2005 Dodge Cummins 48RE to G56/Auto to Manual Swap Complete

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-24-2014 08:04 PM

Merry Christmas! I thought some of you may find this interesting if you've been considering a 6 speed in your common-rail Cummins.

I finished swapping my 2005 from a 48RE to a G56 6 speed last month.

I still have to splice the wires that control the reverse lights in the transmission harness and splice it into the G56 connector, but other than that everything works flawlessly. I will wait until it warms up in the spring to tackle the reverse light issue.

I didn't take a whole lot of photos during the process, mainly because I was taking video along the way. At the bottom of this post you will find a link to the 40 minute Youtube video that is a compilation of all the video and "How-To" I did during the swap.

I hope that I’ve refined a couple dozen hours of research into a single post and am going to present it FAQ style. I hope this information is of value to someone.

Disclaimer:

My swap was taking parts from a late 2005 4x4 with a manual transfer case and putting them into a late 2005 4x4 with a manual transfer case. If you mix up years this information may differ quite a bit. Do thorough research before diving in to this swap. The project as a whole is fairly labor intensive but not impossible….. It’s not slaying a dragon, it’s more like killing 10,000 lizards.

Why didn’t you just build the auto?

I’ve always preferred manual transmissions and loathed automatics. I’ve disliked the auto in this truck since the first day I bought it.... it's probably the biggest automotive mistake of my life. I didn’t like how much the converter slips and I didn’t like how tall 1st gear is. I wanted a 3rd pedal and full control over my gear choice. I don't race or tractor pull with my truck. It's staying stock and all I use it for is towing and hauling my slide-in camper.

Why not just sell the truck and buy one with a 6 speed?

I looked for quite a while, and finding one in the condition in which I’ve kept this one, and/or doesn’t have a pile of miles, and/or isn’t beat to******proved to be nearly impossible.

OK, then why not sell it and upgrade to a newer truck w/ a 6 speed?

For what I could sell my truck, it would have cost me another $5,000 to $10,000 to get into a 6 speed truck in the 08-10 range w/ under 100k miles kept in the same as condition my truck. Swapping made the best financial sense.

Why a G56 instead of a NV5600? I hear bad things about the G56.

Several reasons, but the biggest was the G56 is what "fell into my lap". Had the same deal come available with an NV, I would have went that route.

I did still prefer the G56 over the NV, mainly because NV is no longer in business, and rebuild parts for the 5600 are only available as Asian cheapos. Couple that with with the newest used one is now 10 years old and it makes it much more difficult to rebuild it. Since Mercedes still makes the G56 today, OEM rebuild parts are readily available and low mileage couple-year-old used ones are as well.

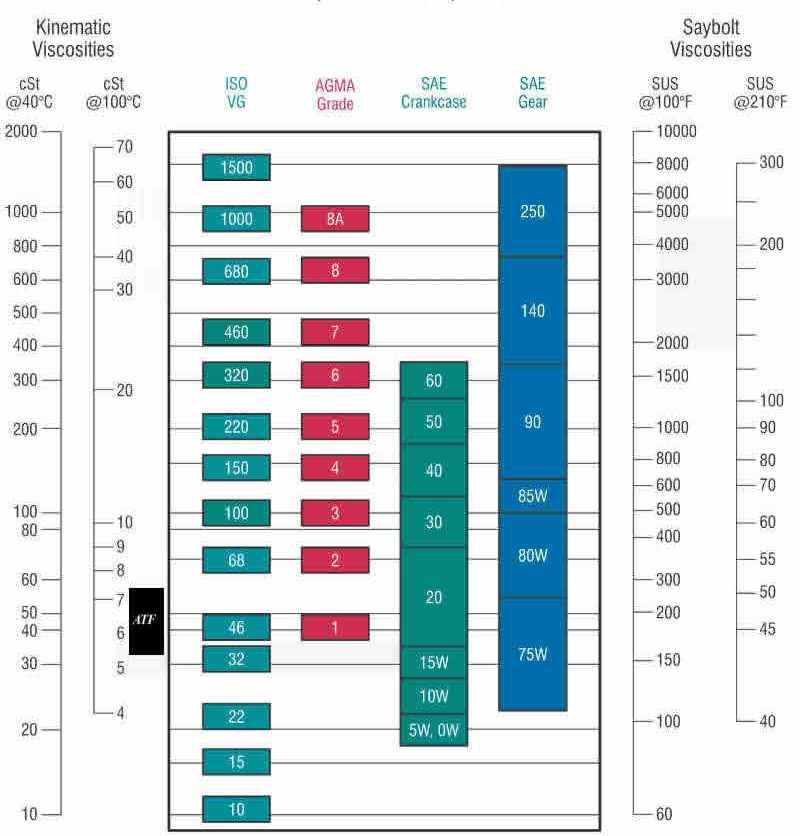

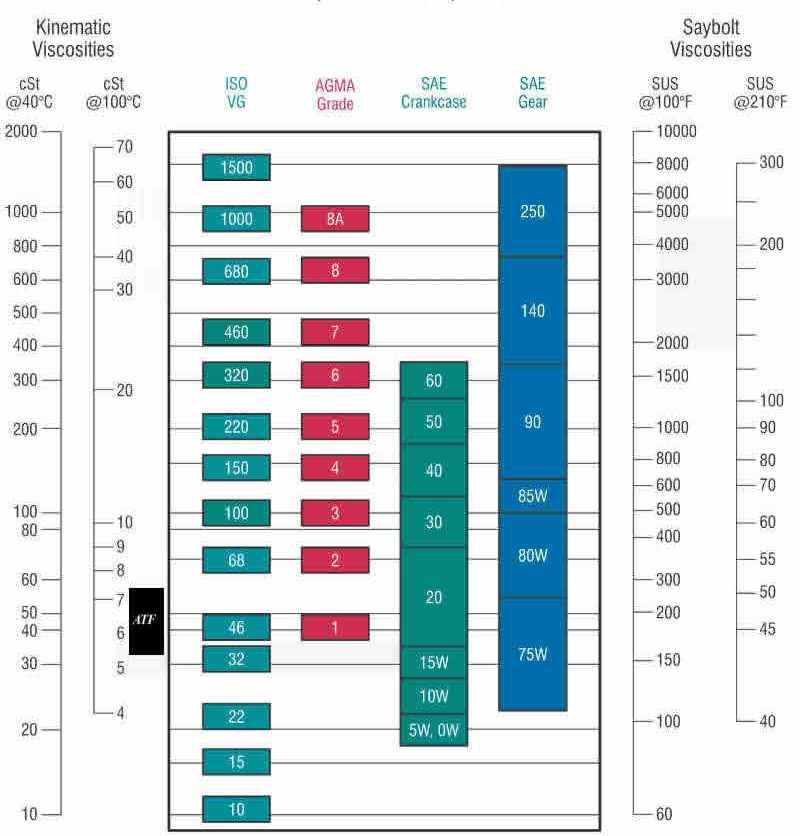

The G56 is plenty strong, and most guys using them for stock towing/hauling applications as I am never have an issue. They get a bad rap from the guys who have 600hp and are doing boosted 3rd gear launches with them. I also think a major part of the failures that people do see has to do with the ATF+4 oil recommended by Chrysler. I think (and research would concour) if you use a proper synthetic manual transmission 50W or 75W90 gear oil, as Mercedes recommends, and overfill it by a quart, you significantly increase the transmission's reliability and longevity. (Refer to Lubrication section below)

I was also not hating the 100 pounds less weight when installing the transmission. The G56 was heavy enough to handle, the extra 100lbs of cast iron that an NV has would have sucked that much more.

Length & Drivelines:

The 48RE is approx. 27” The G56 29”. Because of this you will need to either swap front drivelines with one out of a G56 or have 2” added to it. The rear driveline will need to be swapped out of a truck with the same configuration truck, or have 2” removed. I had 2” removed from mine and it was proably ?” to ¼” too much. You’re safe to go 1.75” to 2” on your length adjustment.

Engine Adapter plate:

The G56 bolts up to the same engine adapter plate as the 48RE. No need to swap this. I have read if you swap in a NV5600 you either need a starter spacer or to swap the adapter plates.

Transfer case

The G56 output is 29 spline. The 48RE is 23. You will either need to change transfer cases or open up your transfer case and put in a 29-spline input shaft. The shift linkage for the transfer case has the 2” of adjustment necessary for the longer transmission, just loosen the bolt, adjust and re-tighten.

Crossmember

The good rule of thumb is that when you get the transmission, get the crossmember for it. All of the 06 and newer (and I believe some of the late late 2005) came with a crossmember that has 3-bolt slots in it, and the G56 had a 3-slot mount. The Mid 05 G56 (Earliest G56) had a 2-bolt mount that uses a 2-bolt crossmember seen in the 03-early/mid 05s did. Just pay attention to this…. you don’t want to have a 2-bolt crossmember and get your transmission with a 3-bolt mount or the other way around.

Mine was the 2005 2-bolt crossmember:

Pedals:

Dodge put the hanger for the clutch pedal in all of the trucks. You only need to swap the brake pedals for one with the narrow pad and install the clutch pedal. Make sure you get all 4 bushings, the pins and clips to hang the pedal correctly

Clutch Hydraulics:

The mounting location for the hydraulic master cylinder on the firewall is in place on the automatic trucks, there is just a knock-out plug on the firewall that needs to be removed and the master cylinder bolts right in.

ECM:

I’ve read that the truck will run with the automatic program in the ECM, but there’s a few annoyance issues like honking when the door is open and check engine lights if this is done. The best bet is to either swap ECMs or have your ECM flashed. You can have a dealer do it or you can use a Smarty programmer. You can even borrow a smarty as you have to un-VIN-lock the Smarty before you can load the recovery file on it. This is what I did. Once you load the factory 6-speed recovery file, the PRND21 indicator on the dash goes away and the computer has no idea the truck was ever an automatic and throws no check engine light.

Shifter & Interior

The column shifter and cable for the automatic comes out with relative ease. You will need to swap the steering column shroud cover with one out of a manual. You will need to cut a hole in the floor for the shift tower. This is the most troublesome and emotionally stressing part of the swap….. cutting the carpet and sheet metal in your precious truck. Just. Do. It. It is so worth it. You will want to use the rubber boot from the shifter as a template for the hole size in the carpet and sheet metal. You will need to delete your fold-down cup holder and replace it with the floor console/cup holders out of one from a manual

Electrical

You will want to keep the wiring harness from the automatic and just tie it up out of the way as you will need several wires on it. A two-wire plug goes into the transfer case and actuates the 4WD indicator light on the dash, and two are for the reverse lights. Additionally, one (Yellow w/ blue trace), which you can get from either the harness or under the hood, will need to tapped into for the clutch safety switch to ground. This is necessary to give you the safety feature of not being able to start the truck without the clutch pedal fully depressed. You can also use a custom momentary switch hidden on/under the dash for added security, but you will not have feature of the cruise being cancelled when you press the clutch pedal which could lead to an overrev situation. At the time of this writing, I have not successfully got the reverse lights working. I am still researching a solution to this.

Misc:

Replace the cheap parts that are hard to access while you have everything out -- rear main seal on the back of the engine and any other issues you may see, and if you’re using a good condition used clutch change out the throw-out-bearing and pilot bearing. Also, prepare to improvise, regroup, stop and do some research then come back to it. Don’t be afraid to ask questions and don’t put an unrealistic deadline on the project. Figure that, like most automotive projects, it is going to cost you twice as much and take 3 times as long as you think.

Lubricants:

This is a topic of great controversy, and there are as many opinions as there are people. I will tell you my research and the opinion and reasoning I decided on. The general consensus is that the ATF+4 that Dodge/Chrysler recommends is not a good plan. Lots of guys run Delvac 50 synthetic manual transmission oil, and that seems to be a very good oil. It is very thick and the climate in which I live (Eastern Montana -- spells of -40 in the winter and 100+ in the summer) and what I use the truck for (Almost exclusively hauling/towing) i decided to go with Red Line 75w90 synthetic manual transmission oil. I chose this because looking at a viscosity chart, the thin end of the multi-viscosity oil is lighter than ATF when cold making shifts easier in extreme cold weather, and the 90w is thicker than the Delvac 50 when warm. And due to the planetary gear set for the low-range in the transfer case, I did run the factory recommended synthetic ATF+4 in the transfer case. Some guys run a blend of Delvac and thinner oil. The long and short is that you need to do your own research, develop your own opinion and run what works best for you, your driving style, and your climate. Additionally, the general consensus is to overfill the G56 by 1 quart (7 quarts total) for added oiling of the front end of the transmission. My transfer case took 2.5 quarts of ATF+4.

Read this thread: MB G56-6 Mercedes Benz Factory Fill - NOT ATF+4!! - Dodge Cummins Diesel Forum

Cost:

The cost on this swap can vary widely on your ability to find deals on parts. If you buy all new parts without a core transmission and pay a shop to do all the labor it’s could run $10,000 or more. If you find someone to trade with and do all the labor yourself it can cost less than $1000. If you wheel and deal on used parts, sell your old stuff you can do it in the $2000-3000 range.

I have about $1450 into this swap by the time I paid the guy with whom I traded the difference in core trans price and for the Southbend dual disk clutch with upgraded hydraulics, shipping, a few odds and ends parts and oil. The trade agreement for the rest of the parts was straight up trade. Below is my rundown of costs:

Trans difference in core price between 48RE and G56: $500

Used Southbend dual-disk, dual-friction clutch w/ flywheel & upgraded hydraulics: $400

½ of shipping: $200

Replacement shift-tower boot: $16

Shorten rear driveline: $130

New throw out bearing, pilot bearing and 10 spline alignment tool: $80

7qts Red Line 75W90 & 3 qts Synthetic ATF+4: $120

Total: $1,446

I also had about a hundred bucks into various tools that I didn’t have already and supplies

Can I really do it?

If you have moderate mechanical & electrical skill and ability, tools found in any garage or that can easily bought, rented or borrowed and a space to do it, the answer is yes. On a scale of 1-10, with 1 being you’ve never changed your own oil and 10 being you’ve been a mechanic for 30 years, I would say this the skill level required for this is a 5 or 6. You should be an experienced home mechanic to attempt this. I would say that my skill level is a solid 6, and I did this project in my unheated, un-insulated, dirt-floor pole barn in using 4x8 sheets of OSB with which to roll around on the creeper. A heated shop with a vehicle lift would have made this project much easier. All in all, it took me about 30 hours from start to finish to do this from loosening the first bolt at the start and tightening the last at the finish. I did all of the labor almost entirely by myself, except for installing the transmission and transfer case. An extra set of hands on this step is pretty much necessary. I probably spent another 40 hours or more reading and researching this project prior to turning a wrench. I started researching the project in April, started accumulating parts in August and September. Since I did a long-distance parts-for-parts trade, pulled the trigger on disassembly in October and finished up reassembly in November.

What tools will I need:

Transmission jack, floor jack set of metric and SAE wrenches, sockets, ratchets, extensions, u-joints of various sizes (Air tools help greatly!!), screw drivers, pry bars, good sheet metal cutting tools, a good creeper…. basically the array of tools an experienced home mechanic would already have. You’ll also need a Smarty (either bought or borrowed) to load the recovery flash into the ECM, and a laptop or tablet to reference back to the online research when you forget specifics.

Most tools that I used are from Harbor Freight. We all know they’re not high-quality but for the home garage they should suffice if you’re on a budget.

In conclusion:

Dodge built these trucks to be equipped with either a manual or automatic, so the swap is not terribly difficult. If you’ve got mechanical aptitude, a good set of tools, some patience, the testicular fortitude to cut a hole in your floorboard, and the unrestrained desire to keep your left foot and right hand from getting bored in your truck. Do this swap. It is so worth it.

How To Video:

https://www.youtube.com/watch?v=PTbcbGHnSlw

I finished swapping my 2005 from a 48RE to a G56 6 speed last month.

I still have to splice the wires that control the reverse lights in the transmission harness and splice it into the G56 connector, but other than that everything works flawlessly. I will wait until it warms up in the spring to tackle the reverse light issue.

I didn't take a whole lot of photos during the process, mainly because I was taking video along the way. At the bottom of this post you will find a link to the 40 minute Youtube video that is a compilation of all the video and "How-To" I did during the swap.

I hope that I’ve refined a couple dozen hours of research into a single post and am going to present it FAQ style. I hope this information is of value to someone.

Disclaimer:

My swap was taking parts from a late 2005 4x4 with a manual transfer case and putting them into a late 2005 4x4 with a manual transfer case. If you mix up years this information may differ quite a bit. Do thorough research before diving in to this swap. The project as a whole is fairly labor intensive but not impossible….. It’s not slaying a dragon, it’s more like killing 10,000 lizards.

Why didn’t you just build the auto?

I’ve always preferred manual transmissions and loathed automatics. I’ve disliked the auto in this truck since the first day I bought it.... it's probably the biggest automotive mistake of my life. I didn’t like how much the converter slips and I didn’t like how tall 1st gear is. I wanted a 3rd pedal and full control over my gear choice. I don't race or tractor pull with my truck. It's staying stock and all I use it for is towing and hauling my slide-in camper.

Why not just sell the truck and buy one with a 6 speed?

I looked for quite a while, and finding one in the condition in which I’ve kept this one, and/or doesn’t have a pile of miles, and/or isn’t beat to******proved to be nearly impossible.

OK, then why not sell it and upgrade to a newer truck w/ a 6 speed?

For what I could sell my truck, it would have cost me another $5,000 to $10,000 to get into a 6 speed truck in the 08-10 range w/ under 100k miles kept in the same as condition my truck. Swapping made the best financial sense.

Why a G56 instead of a NV5600? I hear bad things about the G56.

Several reasons, but the biggest was the G56 is what "fell into my lap". Had the same deal come available with an NV, I would have went that route.

I did still prefer the G56 over the NV, mainly because NV is no longer in business, and rebuild parts for the 5600 are only available as Asian cheapos. Couple that with with the newest used one is now 10 years old and it makes it much more difficult to rebuild it. Since Mercedes still makes the G56 today, OEM rebuild parts are readily available and low mileage couple-year-old used ones are as well.

The G56 is plenty strong, and most guys using them for stock towing/hauling applications as I am never have an issue. They get a bad rap from the guys who have 600hp and are doing boosted 3rd gear launches with them. I also think a major part of the failures that people do see has to do with the ATF+4 oil recommended by Chrysler. I think (and research would concour) if you use a proper synthetic manual transmission 50W or 75W90 gear oil, as Mercedes recommends, and overfill it by a quart, you significantly increase the transmission's reliability and longevity. (Refer to Lubrication section below)

I was also not hating the 100 pounds less weight when installing the transmission. The G56 was heavy enough to handle, the extra 100lbs of cast iron that an NV has would have sucked that much more.

Length & Drivelines:

The 48RE is approx. 27” The G56 29”. Because of this you will need to either swap front drivelines with one out of a G56 or have 2” added to it. The rear driveline will need to be swapped out of a truck with the same configuration truck, or have 2” removed. I had 2” removed from mine and it was proably ?” to ¼” too much. You’re safe to go 1.75” to 2” on your length adjustment.

Engine Adapter plate:

The G56 bolts up to the same engine adapter plate as the 48RE. No need to swap this. I have read if you swap in a NV5600 you either need a starter spacer or to swap the adapter plates.

Transfer case

The G56 output is 29 spline. The 48RE is 23. You will either need to change transfer cases or open up your transfer case and put in a 29-spline input shaft. The shift linkage for the transfer case has the 2” of adjustment necessary for the longer transmission, just loosen the bolt, adjust and re-tighten.

Crossmember

The good rule of thumb is that when you get the transmission, get the crossmember for it. All of the 06 and newer (and I believe some of the late late 2005) came with a crossmember that has 3-bolt slots in it, and the G56 had a 3-slot mount. The Mid 05 G56 (Earliest G56) had a 2-bolt mount that uses a 2-bolt crossmember seen in the 03-early/mid 05s did. Just pay attention to this…. you don’t want to have a 2-bolt crossmember and get your transmission with a 3-bolt mount or the other way around.

Mine was the 2005 2-bolt crossmember:

Pedals:

Dodge put the hanger for the clutch pedal in all of the trucks. You only need to swap the brake pedals for one with the narrow pad and install the clutch pedal. Make sure you get all 4 bushings, the pins and clips to hang the pedal correctly

Clutch Hydraulics:

The mounting location for the hydraulic master cylinder on the firewall is in place on the automatic trucks, there is just a knock-out plug on the firewall that needs to be removed and the master cylinder bolts right in.

ECM:

I’ve read that the truck will run with the automatic program in the ECM, but there’s a few annoyance issues like honking when the door is open and check engine lights if this is done. The best bet is to either swap ECMs or have your ECM flashed. You can have a dealer do it or you can use a Smarty programmer. You can even borrow a smarty as you have to un-VIN-lock the Smarty before you can load the recovery file on it. This is what I did. Once you load the factory 6-speed recovery file, the PRND21 indicator on the dash goes away and the computer has no idea the truck was ever an automatic and throws no check engine light.

Shifter & Interior

The column shifter and cable for the automatic comes out with relative ease. You will need to swap the steering column shroud cover with one out of a manual. You will need to cut a hole in the floor for the shift tower. This is the most troublesome and emotionally stressing part of the swap….. cutting the carpet and sheet metal in your precious truck. Just. Do. It. It is so worth it. You will want to use the rubber boot from the shifter as a template for the hole size in the carpet and sheet metal. You will need to delete your fold-down cup holder and replace it with the floor console/cup holders out of one from a manual

Electrical

You will want to keep the wiring harness from the automatic and just tie it up out of the way as you will need several wires on it. A two-wire plug goes into the transfer case and actuates the 4WD indicator light on the dash, and two are for the reverse lights. Additionally, one (Yellow w/ blue trace), which you can get from either the harness or under the hood, will need to tapped into for the clutch safety switch to ground. This is necessary to give you the safety feature of not being able to start the truck without the clutch pedal fully depressed. You can also use a custom momentary switch hidden on/under the dash for added security, but you will not have feature of the cruise being cancelled when you press the clutch pedal which could lead to an overrev situation. At the time of this writing, I have not successfully got the reverse lights working. I am still researching a solution to this.

Misc:

Replace the cheap parts that are hard to access while you have everything out -- rear main seal on the back of the engine and any other issues you may see, and if you’re using a good condition used clutch change out the throw-out-bearing and pilot bearing. Also, prepare to improvise, regroup, stop and do some research then come back to it. Don’t be afraid to ask questions and don’t put an unrealistic deadline on the project. Figure that, like most automotive projects, it is going to cost you twice as much and take 3 times as long as you think.

Lubricants:

This is a topic of great controversy, and there are as many opinions as there are people. I will tell you my research and the opinion and reasoning I decided on. The general consensus is that the ATF+4 that Dodge/Chrysler recommends is not a good plan. Lots of guys run Delvac 50 synthetic manual transmission oil, and that seems to be a very good oil. It is very thick and the climate in which I live (Eastern Montana -- spells of -40 in the winter and 100+ in the summer) and what I use the truck for (Almost exclusively hauling/towing) i decided to go with Red Line 75w90 synthetic manual transmission oil. I chose this because looking at a viscosity chart, the thin end of the multi-viscosity oil is lighter than ATF when cold making shifts easier in extreme cold weather, and the 90w is thicker than the Delvac 50 when warm. And due to the planetary gear set for the low-range in the transfer case, I did run the factory recommended synthetic ATF+4 in the transfer case. Some guys run a blend of Delvac and thinner oil. The long and short is that you need to do your own research, develop your own opinion and run what works best for you, your driving style, and your climate. Additionally, the general consensus is to overfill the G56 by 1 quart (7 quarts total) for added oiling of the front end of the transmission. My transfer case took 2.5 quarts of ATF+4.

Read this thread: MB G56-6 Mercedes Benz Factory Fill - NOT ATF+4!! - Dodge Cummins Diesel Forum

Cost:

The cost on this swap can vary widely on your ability to find deals on parts. If you buy all new parts without a core transmission and pay a shop to do all the labor it’s could run $10,000 or more. If you find someone to trade with and do all the labor yourself it can cost less than $1000. If you wheel and deal on used parts, sell your old stuff you can do it in the $2000-3000 range.

I have about $1450 into this swap by the time I paid the guy with whom I traded the difference in core trans price and for the Southbend dual disk clutch with upgraded hydraulics, shipping, a few odds and ends parts and oil. The trade agreement for the rest of the parts was straight up trade. Below is my rundown of costs:

Trans difference in core price between 48RE and G56: $500

Used Southbend dual-disk, dual-friction clutch w/ flywheel & upgraded hydraulics: $400

½ of shipping: $200

Replacement shift-tower boot: $16

Shorten rear driveline: $130

New throw out bearing, pilot bearing and 10 spline alignment tool: $80

7qts Red Line 75W90 & 3 qts Synthetic ATF+4: $120

Total: $1,446

I also had about a hundred bucks into various tools that I didn’t have already and supplies

Can I really do it?

If you have moderate mechanical & electrical skill and ability, tools found in any garage or that can easily bought, rented or borrowed and a space to do it, the answer is yes. On a scale of 1-10, with 1 being you’ve never changed your own oil and 10 being you’ve been a mechanic for 30 years, I would say this the skill level required for this is a 5 or 6. You should be an experienced home mechanic to attempt this. I would say that my skill level is a solid 6, and I did this project in my unheated, un-insulated, dirt-floor pole barn in using 4x8 sheets of OSB with which to roll around on the creeper. A heated shop with a vehicle lift would have made this project much easier. All in all, it took me about 30 hours from start to finish to do this from loosening the first bolt at the start and tightening the last at the finish. I did all of the labor almost entirely by myself, except for installing the transmission and transfer case. An extra set of hands on this step is pretty much necessary. I probably spent another 40 hours or more reading and researching this project prior to turning a wrench. I started researching the project in April, started accumulating parts in August and September. Since I did a long-distance parts-for-parts trade, pulled the trigger on disassembly in October and finished up reassembly in November.

What tools will I need:

Transmission jack, floor jack set of metric and SAE wrenches, sockets, ratchets, extensions, u-joints of various sizes (Air tools help greatly!!), screw drivers, pry bars, good sheet metal cutting tools, a good creeper…. basically the array of tools an experienced home mechanic would already have. You’ll also need a Smarty (either bought or borrowed) to load the recovery flash into the ECM, and a laptop or tablet to reference back to the online research when you forget specifics.

Most tools that I used are from Harbor Freight. We all know they’re not high-quality but for the home garage they should suffice if you’re on a budget.

In conclusion:

Dodge built these trucks to be equipped with either a manual or automatic, so the swap is not terribly difficult. If you’ve got mechanical aptitude, a good set of tools, some patience, the testicular fortitude to cut a hole in your floorboard, and the unrestrained desire to keep your left foot and right hand from getting bored in your truck. Do this swap. It is so worth it.

How To Video:

https://www.youtube.com/watch?v=PTbcbGHnSlw

1994 S&S 9.5' SC-B, StableLift, 2x6V golf cart batteries, LED interior lights

2005 Dodge 3500 4x4 QC DRW CTD 48RE to G56 6-speed conversion, Quadzilla 65HP Chip

2005 Dodge 3500 4x4 QC DRW CTD 48RE to G56 6-speed conversion, Quadzilla 65HP Chip

Labels:

- Labels:

-

Tow Vehicles

20 REPLIES 20

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-25-2014 08:56 AM

When my NV4500 gives up OR I find a sweet deal on a G56 I will do it to my 01! The 5 speed has a big jump from 3rd to 4th would to have that extra gear!

GREAT JOB!

GREAT JOB!

Russ & Paula the Beagle Belle.

2016 Ram Laramie 3500 Aisin DRW 4X4 Long bed.

2005 Copper Canyon 293 FWSLS, 32' GVWR 12,360#

"Visit and Enjoy Oregon State Parks"

2016 Ram Laramie 3500 Aisin DRW 4X4 Long bed.

2005 Copper Canyon 293 FWSLS, 32' GVWR 12,360#

"Visit and Enjoy Oregon State Parks"

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-25-2014 05:59 AM

I didn't see it mentioned and gotta' ask but which year model G56 did you go with.

The newer G56 behind the 6.7 have different gear ratios and the DMF.

I have a '03 with the NV5600. The inline 6 cyl Cummins/Jacobs and the 6 speed manual tranny is the sweetest set up for serious hauling (commercial) I've ever had.

The newer G56 behind the 6.7 have different gear ratios and the DMF.

I have a '03 with the NV5600. The inline 6 cyl Cummins/Jacobs and the 6 speed manual tranny is the sweetest set up for serious hauling (commercial) I've ever had.

"good judgment comes from experience, and a lot of that comes from bad judgment" ............ Will Rogers

'03 2500 QC Dodge/Cummins HO 3.73 6 speed manual Jacobs Westach

'97 Park Avanue 28' 5er 11200 two slides

'03 2500 QC Dodge/Cummins HO 3.73 6 speed manual Jacobs Westach

'97 Park Avanue 28' 5er 11200 two slides

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-25-2014 04:36 AM

Nice job, just replaced the bad auto in my 03, and would love to do this swap sometime when I can do without a truck.

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-25-2014 03:22 AM

Great right up!:C

I have and still think about doing this to my 2005. Now that it is a garage queen I am thinking harder about it. I have a buddy at work that did this to his truck and he absolutely loves it. I believe he went with the 5 speed instead though. Don't ask me why.

I have and still think about doing this to my 2005. Now that it is a garage queen I am thinking harder about it. I have a buddy at work that did this to his truck and he absolutely loves it. I believe he went with the 5 speed instead though. Don't ask me why.

2016 Ram 3500 Mega Cab Limited/2013 Ram 3500 SRW Cummins(sold)/2005 RAM 2500 Cummins/2011 Sandpiper 345 RET (sold) 2015 Sanibel 3601/2008 Nitro Z9 Mercury 250 PRO XS the best motor made.

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-25-2014 02:26 AM

I am impressed. Good job.

2014 Ram CTD 4x2 SRW 3.42 68 RE auto trans

Big Horn 3055RL

Restless

San Marcos Tx

Big Horn 3055RL

Restless

San Marcos Tx

Options

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-24-2014 08:23 PM

I can understand your affection for a manual with the Cummins!

After all these years it still puts a smile on my face when I have to take off on a steep grade with my trailer in tow and simply let the clutch out without touching the throttle.

After all these years it still puts a smile on my face when I have to take off on a steep grade with my trailer in tow and simply let the clutch out without touching the throttle.