- Good Sam Community

- Groups

- Truck Camper Group

- Forum

- Re: Our custom true flatbed truck camper build thr...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Our custom true flatbed truck camper build thread

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-18-2013 03:21 PM

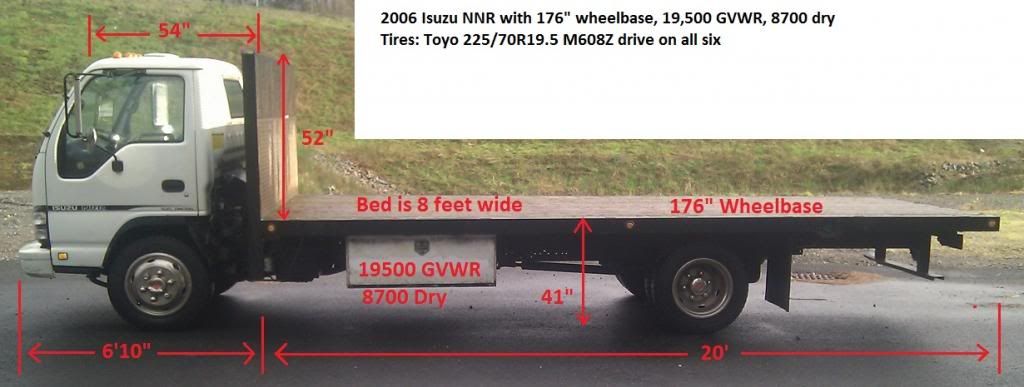

Goal: Construct a true flatbed camper with cabover, no slideouts but full 8 foot floor width inside. This will mount on a 2006 Isuzu NRR truck with a GVWR of 19,500 pounds and a current dry weight of 8700 pounds. The truck has a 20 foot flatbed that is 8 feet wide. The camper will take up 11 feet of the flatbed and the remaining area will be home to a future garage for our toys. We will install a hitch so we can pull our 17 foot Montgomery sailboat (trailer + boat is about 2200 pounds). The camper and garage will be removeable so the flatbed can be used for other purposes, or in case the truck needs extensive shop repairs down the road. Or if we are in Alaska and want to go pick up 3 cords of firewood or something 🙂

Here is a picture of the truck with some important dimensions:

- Labels:

-

Truck Campers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-17-2015 05:15 PM

bka0721 wrote:

But, be aware, in most states Approved Head Protection (helmet) is required and in all states, eye protection is required.

What the what? Huh?

*2012 Chalet Ascent S95R Camper

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-17-2015 04:55 PM

b

09 Lance 1191

1,560wSolar~10-6vGC2-1,160AmpH~Tri-Star-Two(2)60/MPPT~Xantrex 2000W

300wSolar~2-6vAGM-300AmpH~Tri-Star45/MPPT~Xantrex 1500W

16 BMW R1200GSW Adventure

16 KTM 500 EXC

06 Honda CRF450X

09 Haulmark Trlr

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-17-2015 04:46 PM

The rack started as a aluminum Hauler II truck rack for our Tundra which we never got around to installing. It was long enough on the sides but the cross beams were not nearly wide enough (our garage pod is 8'4" like our camper pod). 8020 to the rescue. After cutting about 3/4" off of some standard 97" 8020 aluminum t-slot (2010 series 2"x1") we installed them as cross beams. We added 2"x6" 3/4" thick rubber blocks in three places attached to the 8020 beams to provide extra support from the roof but prevent damage. We machined side brackets that bolt into the steel frame of the garage pod from the side thus keeping to our mantra that a roof should not have any holes.

It is a pretty neat setup. The 8020 T-slots will allow us to put holders anywhere along the beams for different size items (canoe, kayak, aunt Edna) and the 8 foot wide by 10 foot long rack area is fairly large for a truck camper. The garage pod sits a foot shorter than the living pod (which is covered in 1080 watts of solar panels) and thus the items placed on the rack will not cause the overall height of our rig to increase by much if any.

We are not happy with the single cheap winch solution so we are going to go with twin Superwinch Terra 3500 pound models. This is a much better built and much quieter winch. We will pull on the door from each side using the Amsteel winch cable which means you don't have to unhook a Y-harness to drive a motorcycle up the ramp. They can still be unhooked when you want to use the ramp as a porch or work table. We are going to wire the two winch motors in series which will force them to equally share the load of the door (as one winch loads down it's back emf will increase, which diverts power to the other winch which will speed up). They will not have as much power running in series and will be slower but these winches are rated at 25fpm zero load and the cheap winch was 13fpm zero load (and was plenty fast). It will be a safer solution as either winch and cable can support the door on it's own if the other brake or cable fails.

Anyway, here are the pics of the roof rack test fit:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-11-2015 03:33 AM

kereams wrote:

Sounds serious! Is the winch mounted all the way back? Looks like the cable would get in the way but hard to tell with the angle.

No, the winch is mounted near the door. We mounted it far enough back to allow some of the Y harness to pull in but close enough to the door that the cable doesn't bother anything. I made sure I could clear my 6'7" top of head also (by about 2 inches).

It could also be used to pull a disabled toy up the ramp, at least up to the edge. We could place a snatch block on the back wall of the garage pod to pull it in the rest of the way with the same winch.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-10-2015 08:58 PM

So they didn't have the black so I'll have to have it powder coated.

2014 BoonHauler 3614

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-10-2015 06:58 PM

*2012 Chalet Ascent S95R Camper

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-10-2015 06:23 PM

Are you gonna use the jacks to raise the ramp end or merely hold it up? If the former, then it seems to me that the feet of the jacks will need to slide forward and back during the raising and lowering.

2015 Jayco Seneca 36FK

2011 Jeep Wrangler Sport 2 door

2011 R & R 20' Aluminum Enclosed Car Hauler

2007 Montrose 16' Aluminum Flatbed ATV Trailer

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-10-2015 08:35 AM

I like that you will be using it for additional platform. One of the added benefits in having my trailer is to use it during windy and rainy periods. I can be outside of the Truck Camper and still be somewhere out of the rain and wind, to read, eat, and watch the sunrises and sunsets. Good use of space and your Jacks too.

Looks great. Can't wait to see it loaded and full of toys, dirty and worn from use and a bit of scrapes and dirt on the Pod floor.

b

09 Lance 1191

1,560wSolar~10-6vGC2-1,160AmpH~Tri-Star-Two(2)60/MPPT~Xantrex 2000W

300wSolar~2-6vAGM-300AmpH~Tri-Star45/MPPT~Xantrex 1500W

16 BMW R1200GSW Adventure

16 KTM 500 EXC

06 Honda CRF450X

09 Haulmark Trlr

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-10-2015 07:39 AM

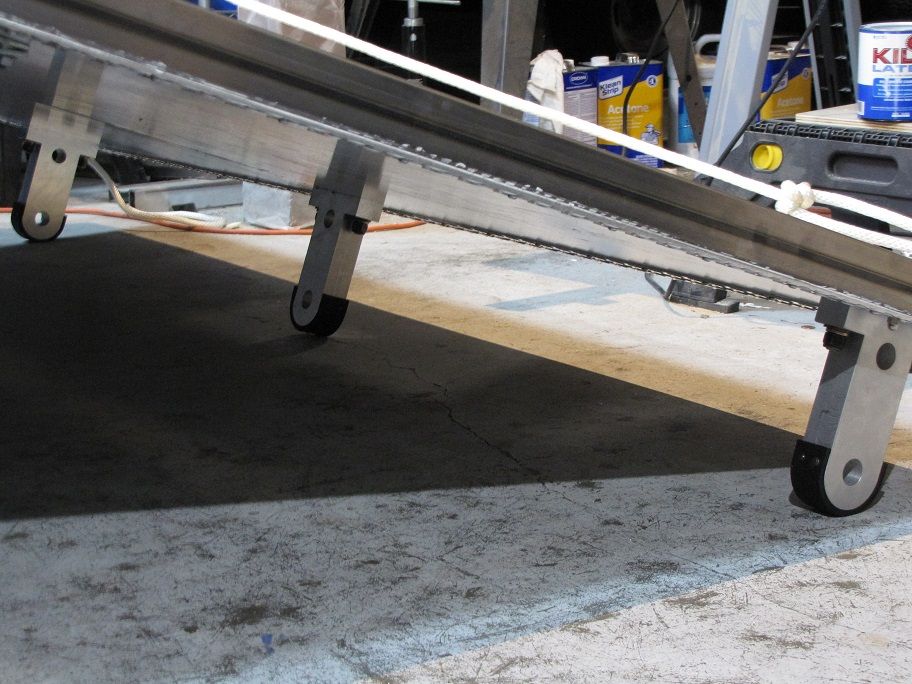

We threw three 1.5" thick blocks of aluminum at our cnc mill and it spit out some beefy aluminum feet for our garage pod ramp door. I am going to miss that mill so much when we hit the road.

The feet serve three purposes. First, they protect the diamond plate edge trim from the concrete/rocks/ground. Second, they elevate the ramp end about 7 inches which decreases the ramp angle on our relatively tall flatbed (40 inches off the ground). Third, they act as receiver tubes for our jackstands which turn the ramp into a stable porch/work platform.

We added some rubber strips to the feet to protect them from hard surfaces and keep them somewhat dent free. They are not *too* heavy but we may do a little pocketing in the sides to shave off a bit of weight. They are fine for now and mate perfectly with the jacks.

Because the door is getting heavy (I am guessing 250 to 300 pounds when the marine ply is installed), we needed a way to raise and lower the door without killing our back. We explored various methods others have used in toyhaulers (side springs, overhead springs with cables, hinge springs) but did not really want to have obstructions on the sides of the ramp when it is being used as a work surface or porch. It would be quite hard to remove a spring under tension after the jacks are supporting the door.

What we have started with is a simple 2500 pound ATV type winch, fastened to a welded bar on the roof in the center of the door width. The winch cable (soon to be Amsteel) is attached to the ramp door with a Y harness clipped on to mounts bolted through the ramp outer frame. (Y harness is temporary nylon rope for testing). It works but is noisy. I guess that is somewhat typical of these small winches. When the ramp door is fully down or has been converted into a porch with the jacks, the Y harness can be unclipped and stored away, leaving a unobstructed three side view.

There are definitely other, maybe better ways this can be done, but this was quick, cheap and will work for awhile. A dual cable system could be made with either pulleys or a rotating bar driven by the winch motor but either solution would add complexity and weight.

Anyway, here are some pictures of the feet and winch, along with a poor video of the door being raised. I don't think I would raise it at 5am at a campground :B

YouTube video: http://youtu.be/a5E6MLQA8EQ

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-10-2015 04:28 AM

BoonHauler wrote:

Jfet:

Quick question for you.

I'm going to order my furnace. Did you paint the front grill or did you order it black like that?

Everything I come up with is the standard Hydroflame brown.

Are you sure two years of research on a furnace is enough? 😉

We ordered it black. I can look up the order and vendor if you are not able to find it in black.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-09-2015 04:09 PM

Jfet wrote:

Jfet:

Quick question for you.

I'm going to order my furnace. Did you paint the front grill or did you order it black like that?

Everything I come up with is the standard Hydroflame brown.

2014 BoonHauler 3614

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-05-2015 11:44 AM

It is a minor thing either way and pretty easy to add/change.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-05-2015 11:06 AM

Harbor Freight sells the e-track in 5' sections (Item #66726) for under $20 each and it is currently 10% off. Combine that with a 20% off coupon and you can buy pieces for under $15 each.

Host Mammoth 11.5 on Ram 5500 HD

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-05-2015 09:53 AM

Also just to let you know my Road Force enclosed trailer (made by Wells Cargo) uses 3 big hinges on the rear ramp door. They have a grease zerk in them to lube them.

I try to always leave doubt to my ignorance rather than prove it

2021 Winnebago View

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Feb-05-2015 08:12 AM

Dartmouth, MA

2021 RAM 2500 4X4 6.4L

2011 Forest River Grey Wolf Cherokee 19RR

520 w solar-200ah Renogy Li-Epever MPPT