- Good Sam Community

- Everything RV

- RV Tips & Tricks

- Re: Reese shim question

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Reese shim question

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-28-2014 12:30 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-30-2014 08:16 AM

By their instructions, it appears they allow 1/2 of their shim thickness (air space) Or 0.021" of gap that the clevis can compress. A lot over that 0.021" and issues may start.

Your concerns about clamping up the head with no shims, this may be better asked, what was the gap?

If you want to have a level of confidence you did not create an issue I know of 2 methods to look for cracks that could tell you if something started.

1. Wet fluorescent magnetic partial inspection. (Magnaflux). Have to find a shop with a big enough magnet to put the head in.

2. Dye Penetrant inspection. Most weld shops have this, are trained and does a good job on cracks wide enough for the penetrant to get into.

Cost. You are up against the cost of the entire hitch head. This price is accurate however that pic is the older 3 piece head. http://www.etrailer.com/Accessories-and-Parts/Reese/RP58167.html

If you have a buddy who is in a weld shop or in a NDT lab, they can do a crack test labor free and only the cost of materials. If you ask for a quote and they quote 1 hour of time, an all new hitch head may be cheaper.

I know the question swirling around in your head, how does one know you created a problem or not??? Good question. There use to be pic's of the cracked heads here on RV.net but last I looked they did not show up, OP may have moved his photo server. Not a pleasant site to see you hitch head cracked in 1/2.

Hope this helps

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-29-2014 08:21 PM

I think I will call Reese on Monday. Is there a chance that I squeezed the clevis together too much by not using a shim (or 2) to start with and otherwise 2 shims may have gone in okay? I was able to get the 2nd shim started and down vertically about an inch.

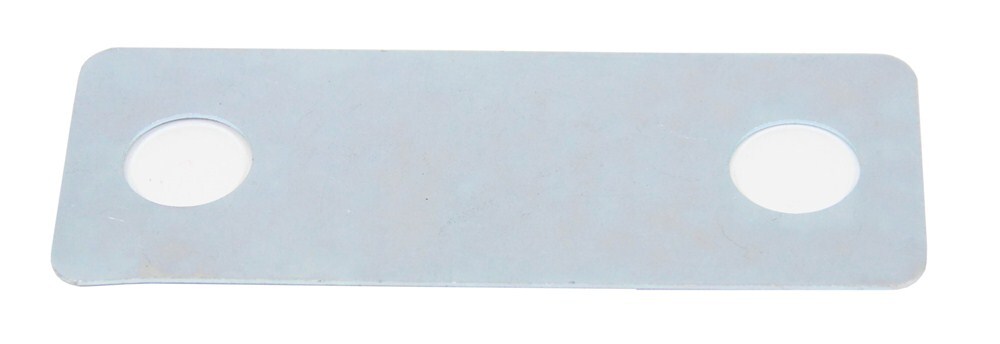

I wonder it a person could just get an appropriate thickness of sheet metal that would be around 0.02 to 0.03 inches and just make up a shim?

Our Reese hitch is just a year old and the cast steel type.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-29-2014 03:10 PM

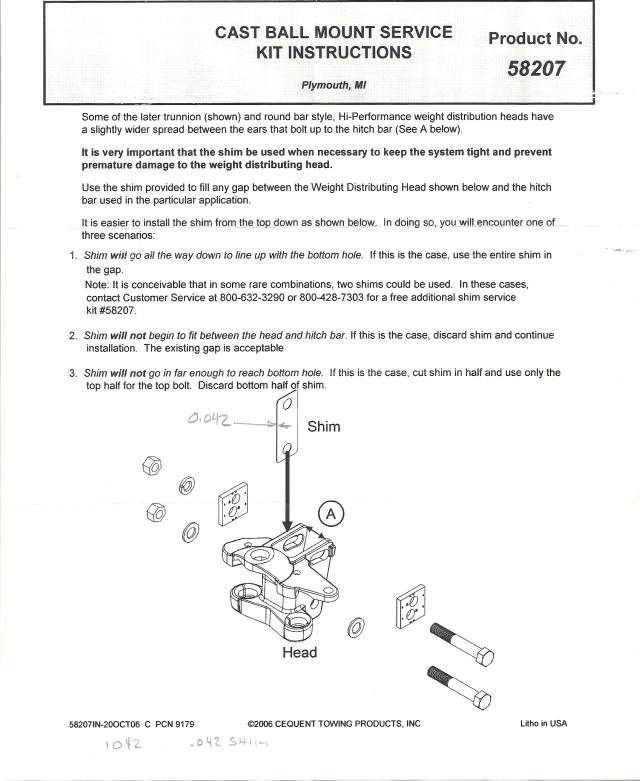

Here is the sheet explaining the shim

That sheet came with all steel cast head I bought a few years ago. The current day HP Trunion bar head.

I also have the 3 piece welded head in my collection of Reese parts. Prior to this 3 piece vintage was an older all cast steel head. Time frame approx. year 2,000 ish. During that time frame some heads cracked potentially due to the fit up to the shank. Some folks where not using or did not know to shim, so they over tightened to try and compress the clevis. The result in some cases was reported to lead to a cracked head. There was also "talk" of a casting issue in some cases however an official recall was never issued that I am aware of.

From this sequence of events the new 3 piece HP hitch head was born around approx. 2002 to 2003 time period and the older all cast head part numbers were discontinued. I have 3 of 3 piece those heads. They have a mild steel clevis welded to forged top bottom trunnion sockets. The softer steel conformed to the shank very easy.

As time progresses, Reese came back with the all cast steel head which is now offered. It was an updated design. The shim paper comes with some but not all, don't know why, dealer may loose the paperwork etc.

I myself would not over torque the bolts trying to compress an all cast steel head. I called Reese on the shim and tech service told me the head can be used as the flyer I posted and the clevis can flex enough to make the shim work but to not over do it not using the shim. The shim was 0.042" the tech had told me. That may help in understand of the distances.

A call to tech service may give an updated version of the shimming process if it has changed in the last few years.

Hope this helps.

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-29-2014 10:22 AM

DutchmenSport wrote:

Would you be so kind as to explain or show a photo of what a jamb bolt is with respect to a trailer hitch? Searching on the internet, all I getting are door parts, specifically, the recessed handles used on pocket door, or parts for household storm doors. I've never heard that term before (and I've done a lot of home construction and remolding).

Drill a 1/2 inch hole in the top of the receiver, I like to go in front of the pin hole so the bolt will push the hitch downward and give more support. Take a 1 inch long 1/2 inch coarse bolt put some anti seize on the threads and thread a nut all the way down, insert the bolt with nut into the hole and weld the nut to the receiver. After it's cooled back the bolt out until the hitch will go into the receiver, put the pin in and tighten the bolt. For a bike rack or something light the top one is all that's needed but for heavier towing or carrying you can also put one in the side.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-29-2014 09:46 AM

2007 Chevrolet 2500HD 6.0L

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-29-2014 08:14 AM

After careful examination of the hitch head, (I did that at home), it actually sits 1/2 inch higher than on my old truck. (Remember we traded trucks last Wednesday). So when you consider our trailer is 35 feet long, that 1/2 inch magnified over 35 feet does make a noticeable non-level look now. Also, turns out no matter how I try to adjust the head, the ball is leaning slightly backwards. The tech guys said the head is bent (ouch!).

Well, one thing I am very anal about is insuring I'm hitched properly to the right truck and I've always been the advocate for absolutely safety first!

So after discussing with the tech guy, I went ahead and purchased an Equalizer Hitch. Because today is Saturday, I'm taking the truck and camper (with the bent head) back on Wednesday and they are going to install it, (and get it set right).

So, that's the solution! That and a few hundred dollars for the new hitch system! 😞

Well, I really don't feel too bad though. New camper September 2013, new truck March 2014, new WD system March 2014!

My old Reese system was purchased in 2005, and it's towed 3 TT's now. I suppose it's time for a change!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-28-2014 07:54 PM

oilslick wrote:

The common fix and often comes standard on a lot of receivers is a couple of 1/2 inch jamb bolts, one on the top and one in the side, no more play anywhere. Forget the shims.

Would you be so kind as to explain or show a photo of what a jamb bolt is with respect to a trailer hitch? Searching on the internet, all I getting are door parts, specifically, the recessed handles used on pocket door, or parts for household storm doors. I've never heard that term before (and I've done a lot of home construction and remolding).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-28-2014 05:58 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-28-2014 05:29 PM

I believe the shims are supposed to come with your complete WDH setup but I didn't get them and never heard of them before. I thought the play was normal. I don't like the idea of tightening the bolts up to bring each side of the head together.

Reese says it's only in occasional cases where two shims are needed. I'm hope I haven't bent the head a bit to prevent two shims from fitting.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-28-2014 04:00 PM

2007 Chevrolet 2500HD 6.0L

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Mar-28-2014 02:55 PM

After unhitching from the test drive, I realized and felt the slack between the shank and the head. So, I've been on a campaign to do something about that.

I checked with Modern Trailer in Anderson, IN, and basically, to get a hitch with the larger shank to fit my truck now, will require purchasing a whole new WD system. I really don't want to do that. They said most people are just using the hitch insert.

I then asked about the slack between the 2 parts. Funny, I NEVER noticed this before until 5 days ago during the test drive, so I don't know when this started.

Evidently, it's not a real problem. The last trip we made was over Christmas when we went to Florida for a week, towing with the old truck. No problems or anything, but the slack had to be present, I just didn't know it.

So, the guy at Modern Trailer suggested putting a washer in there to take up the slack. Only problem, it takes a very, very thin one, and then it's going to have to be wedged in there.

Well earlier today I took the two pieces apart to see if any washer would fit. I don't have anything that thin. So I came up with the following idea.

#1. I'm taking the time to wire down the shank and the head and getting rid of all the old loose rust and then going to repaint them with some good old fashioned Rustolium. I'm hoping the paint may be all it takes to fill that gap.

If that does not work, my next idea is to use a bit of old inner tube and cut out a make shift washer, spacer with that. I know that probably will not last long, I expect it to wear if there is any movement at all, but if it helps quiet down the clang, clang I'm OK with that.

One thing I also thought about, just like you, was to compress the two sides of the hitch head that wraps around both sides of the shank. I DID rule out that idea though, think that could potentially weaken the head, and the last thing I want is a broken hitch at 60 miles per hour.

So, your post is absolutely right on time! If I have any success, I'll definitely do a follow up on this post and let you know what happened.

Do you think paint will be enough to do the job?

- Reese Straight Line Weight Distribution Hitch Question in RV Tips & Tricks

- Reese dual cam… driver side seems to have more tension. in RV Tips & Tricks

- New Shank for 2021 GMC Sierra 2500HD in RV Tips & Tricks

- Questions about Reese straight line setup. in RV Tips & Tricks

- Upgrading WDH hitch, Shank question. in RV Tips & Tricks