- Good Sam Community

- Everything RV

- Technical Issues

- Bad receptacle installation by factory - potential...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Bad receptacle installation by factory - potentially unsafe

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-24-2017 01:30 PM

The hot and neutral wires were only pushed onto one of the two terminals instead of two as specified by the manufacturer and as required by the UL/CSA certification. This means that the receptacle is only capable of carrying 1/2 it's current rating - 7 1/2 amps. Where higher rated appliances are used like say in a kitchen, this could lead to overheating. Worse, if someone has a heater plugged in and it runs non-stop for long periods of time, that would create an even higher risk of overheating. Note also that the romex/loomex cable sheath does not extend inside the receptacle housing as it is required to.

I've also found two receptacles with reverse polarity and a wire at a breaker in the converter/panel that was completely loose. KZ needs to look at their electrical practices and code compliance. I've also found numerous issues with the 12 volt wiring too. I am NOT impressed. :M

KZ is not alone though. The second photo is from a previous Coachmen Catalina TT that we used to own and you can see the hot wire connected to one terminal only there too. You can also see how the terminal was damaged and it appears that they did not use the correct tool. In two out of two TTs that I've pulled receptacles out of the wall, they've both had the same problem. Not good odds.

Receptacles in RVs are designated "SCD" for self-contained device and do not require an outlet box. These are also use in mobile homes. They are CSA or UL tested and are completely safe to use and do not ever need to be removed and replaced with a residential type (and outlet box) with screw terminals. The MUST be properly installed though and that is where RV factories are at fault. There is a special tool to "punch down" the wires onto the terminals and there is no excuse for not doing it correctly. This catalogue from Hubbell has detailed info. on their Wirecon SCD and explains how they are to be installed.

RVs are required to be wired according to the NEC, which is very detailed on what is required. Plus electrical appliances, wiring devices (recepts. & switches), wire, etc. are required to be UL or CSA certified. The problem is - there is no authority having jurisdiction or electrical engineer that is required to inspect the work for code compliance. To make it even harder, RVs are built in one state and shipped all over the US and to Canada so what AHJ would be responsible? I might consider notifying the electrical safety authority but would it be a state official or would it go to a federal authority?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-21-2017 11:01 PM

Currently, Henniker NH

07 Fleetwood Discovery 39V

1K Solar dieselrvowners.com

2005 Jeep Grand Cherokee

Prior:1993 Pace Arrow 37' Diesel

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-21-2017 04:41 PM

In another time and place we had a favorite saying, it applies here (and in many other places) as well.. From the old "mobile economy run" ratings on automobiles.

"Your Millage May Vary"

IN context it measns laws and licensing requirements may vary from state to state, city to city within the state, It may make a difference if the electrian is workign on your house, or in a factory where houses are built or where motorhomes/trailers are built... Many variables.

Factory OWNERS are very good at finding where they can build to take advantage of these differences in laws.. Now do not get me wrong, I'm not complaining about this, IF I were to build a factory.. I'd do the same thing. I mean why hire a 25 dollar an hour licensed union man when I can pay 15 to someone not licensed?

Of course it may affect their liability insurance cost in the long run.

But never assume the licensing requirements WHERE YOU PARK are the same as WHERE I PARK or where the RV was built... Unless you are parked at the factory.

2005 Damon Intruder 377 Alas declared a total loss

after a semi "nicked" it. Still have the radios

Kenwood TS-2000, ICOM ID-5100, ID-51A+2, ID-880 REF030C most times

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-21-2017 03:06 PM

Yup. And when my back aches and arthritic fingers complain about soldering # 6 fork terminals to thnn then tightening the snot out of the binding screw, memory of threads like this kick in and discomfort level eases. Wotta hoot.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-21-2017 02:38 PM

fj12ryder wrote:dougrainer wrote:Maybe your definition of "Licensed" and mine differ, but to legally do electrical work for someone in Missouri, you have be licensed in Missouri. There is no statewide licensing but you have to be licensed in the area where you are working.

Licensed Electricians on staff? HOW many residential/commercial electrical work is actually looked at by the Licensed Electrician? I doubt the Licensed Electrician will go behind EVERY receptacle that is installed by his crew and verifies that it is done correctly. Now, I find your claim suspect. Why? because how many people take pics of outlets and just happen to state that I had a previous other brand with the same problem? I took pics? Now, to claim that because you have seen a few, the ENTIRE industry is suspect????????? Sorry, you are just bring up a non issue. Doug

"Now, I find your claim suspect." If you're mistaken about this where else have you erred?

"Tens of thousands"? That could work out to 5 units a day, 7 days a week, 52 weeks a year, for 20 years. Would that fall under the heading of "Exaggeration for effect"? 🙂

To take that a little father, it's actually the contractor that is licensed in the municipality where the work is to be performed. My son does electrical work around the KC area and pays a licensed contractor 10-20 percent to pull the permit. Contractors will do this only for those that get it right and pass inspection the first time.

Richard

2013 CRV Toad

2 Segways in Toad

First brake job

1941 Hudson

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Jun-21-2017 10:24 AM

Just a taste..

Lynnmor wrote:

...This thread went from using the type of wire connection to retention force. Pushing a wire into a slot and hoping that the slot doesn't widen or distort too much is not a product I care to use. The majority of my working life was in the connector industry and have built, developed and maintained the dies that produce those slots. All I can say is good luck using them with high loads.

This is why I frickin' love this forum! Any bit of industry, obscure or otherwise, we have someone with a few decades of expertise!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-26-2017 06:21 PM

fpresto wrote:myredracer wrote:

I removed a receptacle in our KZ Spree TT

What was KZ's reply when you brought the issue to their attention?

Have not contacted them. I suspect it would be a waste of time.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-26-2017 05:43 PM

Another RVer reported his did burn through and arc.. He caught it in time however so he was able to say how it happened.

As I said, I do not like 'em. the OP showed you a photo of WHY.

2005 Damon Intruder 377 Alas declared a total loss

after a semi "nicked" it. Still have the radios

Kenwood TS-2000, ICOM ID-5100, ID-51A+2, ID-880 REF030C most times

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-26-2017 03:03 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-26-2017 02:29 PM

myredracer wrote:

I removed a receptacle in our KZ Spree TT

What was KZ's reply when you brought the issue to their attention?

2016 Tiffin Allegro 32 SA

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-26-2017 01:16 PM

Any claim that UL is derelict is going to face 9 regiments of courtroom battle hardened attorneys. I simply do NOT trust UL as an all encompassing guarantee of safety anymore. The certificate is a basic better than nothing start but I am reminded of the FAA and the forbidding of soldering because of risk of PMA license revocation. The FAA and countless drones mimic the words. SOLDER! VIBRATION! FAILURE!

I respond with SOLDER! ALTERNATOR! STARTER MOTOR! ELECTRONICS! After which I hear dead silence. The reason is skewed. Soldering is prohibited because few mechanics know or want to learn the technique of soldering. I was called on the carpet decades ago for soldering an electrical harness running between the alternator, voltage regulator and Over Voltage Limiter on a Lycoming engine. Another PMA mechanic freaked when he saw (SHRIEK!) heat shrink tubing. I got off on a technicality that exempted charging system harness interconnections.

God forbid anyone challenging bureaucratic rote.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-26-2017 01:06 PM

myredracer wrote:Horizon170 wrote:Lynnmor wrote:

I replaced the cheap junk self contained outlets with real residential outlets in a box. The idea that electricians and inspectors are part of the process is not the reality in the RV business.

I have searched and searched and can not find any U.S.A. made duplex.

I did find a couple of good made in USA used at a thrift store.

May someday we can find new ones made in the USA.

That could be true at the retail/residential level. I would try an electrical wholesaler - where the contractors buy "the good stuff". I've often avoided retail electrical items as sometimes you get what you pay for. Some receptacles are made in the US like in the photo. I have never heard of Trademaster - sounds like a name the Chinese would use (like Chicago Electric, eg., lol). For US made recepts. I would look for Hubbell, Cooper, P&S, etc. which probably means going to "spec. grade."

THE most important thing to know is that any device that carries a UL or CSA marking has gone through a long, detailed and rigorous set of tests in order to become certified and legally able to carry the designation and as a result ensures a level of safety to the public. As Mex mentioned, there are a number of grades of receptacles and have the lowest to higher retention force, larger contact surface area and best (lowest) contact resistance with the best being hospital grade. Being US made doesn't necessarily mean better quality in the case or recepts. Recepts. and other wiring devices MUST be UL or CSA certified to be sold & used in the US and Canada.

Please note that I never mentioned "made is USA" as it is getting to be impossible to buy anything but imported. This thread went from using the type of wire connection to retention force. Pushing a wire into a slot and hoping that the slot doesn't widen or distort too much is not a product I care to use. The majority of my working life was in the connector industry and have built, developed and maintained the dies that produce those slots. All I can say is good luck using them with high loads.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-26-2017 01:00 PM

Blacklane wrote:

If you're going to install residential outlets in an RV, at least don't use the screws on the side: use the spring-loaded quick connect kind. Vibration can loosen screws, causing huge risk of arc and fire. That's why RV electrical devices have the punch-down connectors and self-contained boxes that are made to hold the wires in-place.

Sorry, but I can't agree with that. There are many screw terminals in RVs that are just fine. When it comes to a wire-to-wire connection, there is a "vibration-proof" wire nut available (UL/CSA too). It employs a screw connection under the cap.

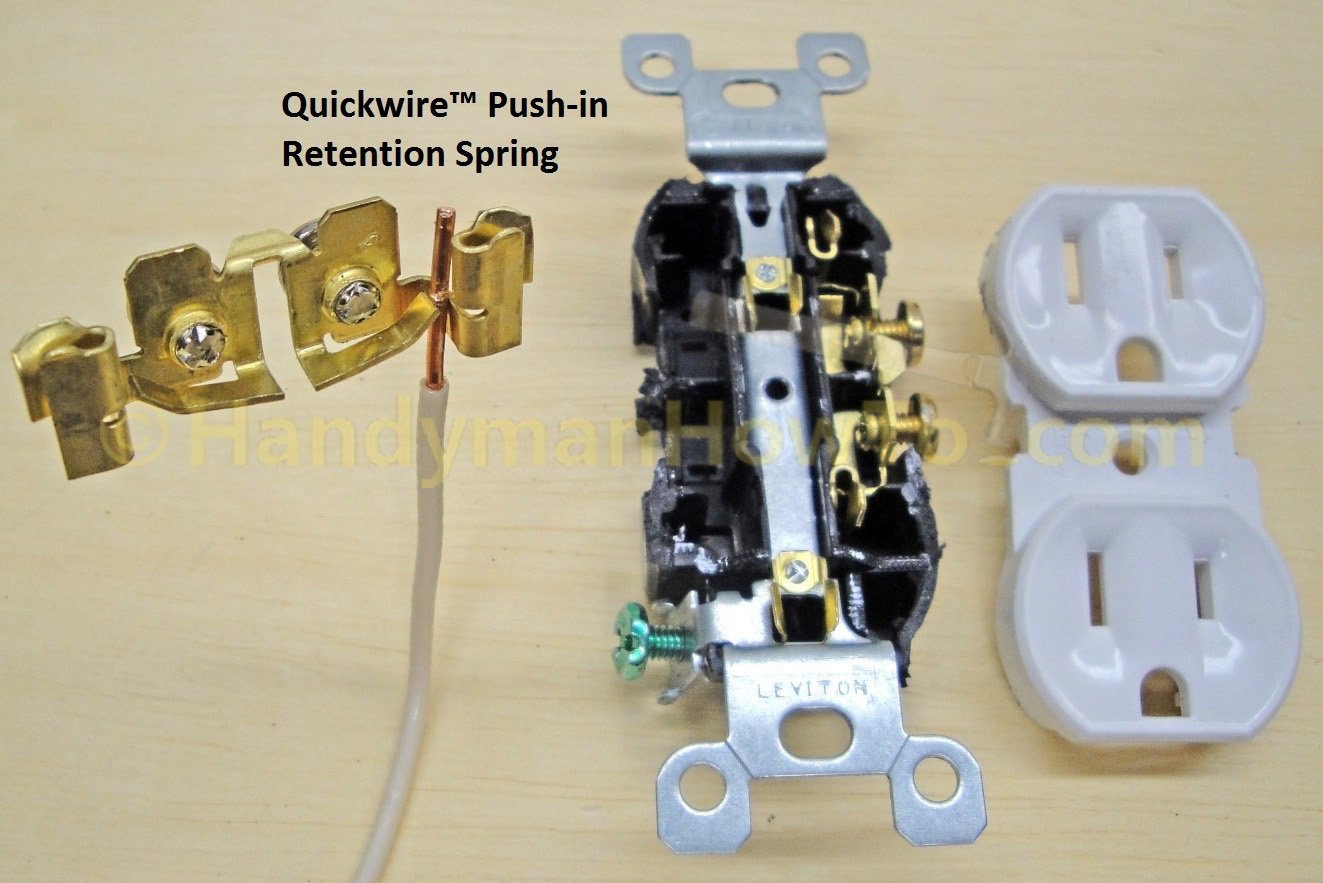

The back-stab connections on a residential recept. aren't generally well regarded in the elec. biz because they are spring loaded and there's no way of seeing the connection. Fourth pic shows what they look like inside. I'd take an RV SCD recept. connection over one of these any time.

The key to creating a trouble-free connection is doing it properly. There are no shortcuts or excuses. The second pic is from a splice in our TT. This is not the way to do them (have found a few more like this too). Best practice is to "pre-twist" the wires before installing the wire nut. I like to use the vibration-proof set-screw wire nuts in cases like this. How 'bout another example from our TT. Third pic is the #6 + wire from our battery and it simply fell out when I touched it because the factory didn't apply enough force on the crimp. This is potentially serious as it could prevent operation of the brakes if the break-away switch activated from a disconnected hitch while travelling.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-26-2017 12:49 PM

I was connected to a 15 amp shore power supply. Voltage was good. Yet, it burned up the brand new 30 amp Cameco female outlet, and in the process destroyed the 30 amp Cameco male plug, too. The outlets had been treated with anti corrosion spray. Ambient temperature was 4.5 c (40 f)

How is it possible for a 30 amp connector in new condition to fail in that situation? Bad OEM design on the female is my guess.

My ride is a 28 foot Class C, 256 watts solar, 556 amp-hours of Telcom jars, 3000 watt Magnum hybrid inverter, Sola Basic Autoformer, Microair Easy Start.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

May-26-2017 12:44 PM

Horizon170 wrote:Lynnmor wrote:

I replaced the cheap junk self contained outlets with real residential outlets in a box. The idea that electricians and inspectors are part of the process is not the reality in the RV business.

I have searched and searched and can not find any U.S.A. made duplex.

I did find a couple of good made in USA used at a thrift store.

May someday we can find new ones made in the USA.

That could be true at the retail/residential level. I would try an electrical wholesaler - where the contractors buy "the good stuff". I've often avoided retail electrical items as sometimes you get what you pay for. Some receptacles are made in the US like in the photo. I have never heard of Trademaster - sounds like a name the Chinese would use (like Chicago Electric, eg., lol). For US made recepts. I would look for Hubbell, Cooper, P&S, etc. which probably means going to "spec. grade."

THE most important thing to know is that any device that carries a UL or CSA marking has gone through a long, detailed and rigorous set of tests in order to become certified and legally able to carry the designation and as a result ensures a level of safety to the public. As Mex mentioned, there are a number of grades of receptacles and have the lowest to higher retention force, larger contact surface area and best (lowest) contact resistance with the best being hospital grade. Being US made doesn't necessarily mean better quality in the case or recepts. Recepts. and other wiring devices MUST be UL or CSA certified to be sold & used in the US and Canada.