- Good Sam Community

- Groups

- Travel Trailer Group

- Forum

- Re: Equalizer Hitch Question

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Equalizer Hitch Question

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-23-2014 05:58 AM

2014 Dodge Ram 1500 5.7. 4x4

Firestone Air Lift 1000, Equalizer Hitch

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-30-2014 05:11 PM

Just follow the manufactures cleaning/lubricatiob instructions

Glad I didn't waste my money on the Hensly or Pro pride system .

Towing my 31 ft. Cougar across Galveston/Surfside toll bridge with wind gusts of 50 + MPH with my 2500 Hemi Ram 4x4 & E4 hitch with 0 sway .

Glad I got it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-30-2014 04:56 PM

RinconVTR wrote:

Ron - you are clearly out of your element here.

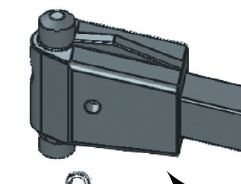

I don't have my hitch on hand this very minute, but this is the E2 knuckle picture from the manual, and the top and bottom protruding "shafts" have radius ends. BALL ENDS.

What got me worked up was people claiming there is more friction at the lubricated head (be it knuckle of the E2 or square socket end of the Equalizer) has drastically more friction to reduce sway than the the un-lubricated L brackets. Its as simple and ridiculous as that.

If you have an E2 I can see where you say the lubricated knuckle end does not offer any sway control. Your provided pictures to my non engineering eye do seem to support your claim. But I do think your claim of the square socket end of the 4 way not playing a large part in the sway is entirely incorrect.

I happen to have been getting ready to post a step by step disassemble of my 4 way on the DIY forum, so I have a few pictures I can post here. I always kept the head lubed and you will see from the wear that there is a large amount of force applied by the sockets.

This is a bottom up picture of my hitch. In the picture you can see how the square sockets slide in the head as the trailer turns. the red dot in the picture is the bottom of the nut for the hitch ball.

Below is a picture of a square socket with the grease wiped off. You can see the polishing that occurs on the sockets from the wear. The sockets are case hardened so they are not gouged from the sliding pressure in the head.

Now two pictures of the the head with the square sockets removed and the grease cleaned off. In these pictures you can see the wear caused by the sliding sockets in a well greased Equal-i-zer 4 point sway control hitch. For those of you who run this hitch I would strongly suggest you annually disassemble it and inspect.

Top:

Bottom: the white specs are from the paper towel I used to clean the head.

To my non engineering eye these wear marks in spite of the grease are a strong indicator of where the real pressure is in the system.

2001 Suburban 4x4. 6.0L, 4.10 3/4 ton **** 2005 Jayco Jay Flight 27BH **** 1986 Coleman Columbia Popup

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-30-2014 03:45 AM

RinconVTR wrote:

...My point about the joint design and friction at the head/trunnion and L brackets is being heavily misunderstood....

Be careful you don't trip while doing all that back peddling. 😉

The manufacturer of the Equal-i-zer has claimed since the beginning that the majority of the sway control was at the hitch head end of the spring bars. Not being an engineer nor having played a role in the design of the system, I take their word for it.

My personal observation of wear on the surfaces of the Equal-i-zer hitches is that the manufacturer is correct. I didn't just read and look at pictures, I have owned and used two of them.

2016 Silverado 3500HD DRW D/A 4x4

2018 Keystone Cougar 26RBS

2006 Weekend Warrior FK1900

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-30-2014 03:39 AM

BulldawgFan wrote:

The E2 hitch is only weight distributing, no sway control, no lubrication related to sway on an E2 is a non-issue anyway.

Try again.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-30-2014 03:33 AM

ROBERTSUNRUS wrote:

🙂 Hi, so let me get this straight. You are saying or insinuating that the spring bar sockets can't work because they are lubricated. .

Not what I said.

Again, the debate started first with lubricating the L brackets, then things really got going with a claim that the lubricated "spring bar sockets" create more friction...drastically more...than at the dry L brackets.

There is tremendous friction at both locations, but if we're talking effectiveness and percentages to which end has more, it is the L brackets.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-30-2014 02:59 AM

2011 GMC Terrain (Toad #1)

1993 Jeep YJ (Toad #2)

1993 EZGO Marathon 48v

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2014 10:54 PM

RinconVTR wrote:

Ron - you are clearly out of your element here.

I don't have my hitch on hand this very minute, but this is the E2 knuckle picture from the manual, and the top and bottom protruding "shafts" have radius ends. BALL ENDS.

What got me worked up was people claiming there is more friction at the lubricated head (be it knuckle of the E2 or square socket end of the Equalizer) has drastically more friction to reduce sway than the the un-lubricated L brackets. Its as simple and ridiculous as that.

🙂 Hi, so let me get this straight. You are saying or insinuating that the spring bar sockets can't work because they are lubricated. Then going by that, automatic transmissions wouldn't be able to move your car or truck because the all of the clutches are soaked in oil. Therefore they will just slip. Anyway, whatever you believe, my Equa-i-zer hitch has been doing a great job for over ten years and many tens of thousands of miles. Grease or no grease the angle of the head with the pressure on the spring bars, and the clamping force of the socket bolts, there is a lot of resistance/friction there.

2005 Airstream Safari 25-B

2000 Lincoln Navigator

2014 F-150 Ecoboost

Equal-i-zer

Yamaha 2400

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2014 07:24 PM

I don't have my hitch on hand this very minute, but this is the E2 knuckle picture from the manual, and the top and bottom protruding "shafts" have radius ends. BALL ENDS.

What got me worked up was people claiming there is more friction at the lubricated head (be it knuckle of the E2 or square socket end of the Equalizer) has drastically more friction to reduce sway than the the un-lubricated L brackets. Its as simple and ridiculous as that.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2014 05:02 PM

RinconVTR wrote:The front end of an Equal-i-zer 4-Point WD bar is attached to the socket using a Socket Pin and a pin clip.

The Eqaulizer does not have a ball and socket joint, the spring bars have no attachments on the ends, and the square socket they fit into is fixed to the head.

The socket is NOT "fixed" to the head. The socket CAN rotate relative to the head. It is held in place by, and pivots around, a "socket bolt" which should be torqued to 45-65 lb-ft.

This torque ensures that the top face of the socket remains in good contact with the underside of the top of the head so adequate rotational torque can be generated.

The E2 calls the spring bar end a knuckle (which has ball shaped ends)The knuckle is bolted to the spring bar, which fits into the trunnion (head).Yes, Fastway does call their WD bar socket a "knuckle".

However, the socket does not have "ball shaped ends". The socket is mated to the head via trunnions on the top and bottom faces of the socket.

From the E2 manual since we're mostly talking about the E2 ball end; They say to lubricate the ball ends as routine maintenance, and state in bold...DO NOT LUBE THE L-BRACKET JOINT.The manual does not refer to "ball ends".

The manual states: "

The contact points of the head and trunnion knuckles should be kept clean and well lubricated with a good quality lubricant.

"Equalizer also says to lube the socket ends at the head as routine maintenance, but backs off when they mention the L brackets and suggests "a better option".If the friction surfaces of the head and sockets are not kept clean and lubricated, they are capable of generating far more wear and rotational torque than desired.

Lubricating the bar/L-bracket contact surface is optional because the contact force (and friction force) is less than for the sockets, and wear is not as much of a problem if the surfaces are not lubricated.

My point about the joint design and friction at the head/trunnion and L brackets is being heavily misunderstood.I believe your point was:

"

---The ball sockets are indeed defined at part of the "4 point" system, but have little to no effect on sway in reality vs marketing.

The ball sockets (trunnion knuckles) allow the trunnion bars to articulate left to right, they DO NOT resist trailer sway at all. Driving in a straight line, there is ZERO movement at the ball sockets. Sway control on such systems like the E2 and Equalizer is 100% on the L brackets.

I believe that all of those who disagree with you have understood your point quite well.

Short form; A lubricated ball end or pivoting joint with sliding surfaces will absolutely NOT have more friction than a bare metal to metal flat surface.This is correct -- however, it really has nothing to do with the point you were making.

So basically, some of you are fiercely debating the amount of friction of a lubricated joint vs dry joint. Wow. I give up. You win.The main problem with all of your assertions is that lubrication does not eliminate friction force, it simply reduces it.

Ron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2014 12:02 PM

lbrjet wrote:

Just the fact that you keep using the term trunnion knuckle (plus ball socket) tells me you are confusing the Equal-i-zer 4 point with some other hitch. These terms are not found anywhere in the EQ manual.

I did clarify there are two different brands and trunnion bar end types being discussed here.

The details are;

The Eqaulizer does not have a ball and socket joint, the spring bars have no attachments on the ends, and the square socket they fit into is fixed to the head.

The E2 calls the spring bar end a knuckle (which has ball shaped ends)The knuckle is bolted to the spring bar, which fits into the trunnion (head).

From the E2 manual since we're mostly talking about the E2 ball end; They say to lubricate the ball ends as routine maintenance, and state in bold...DO NOT LUBE THE L-BRACKET JOINT.

Equalizer also says to lube the socket ends at the head as routine maintenance, but backs off when they mention the L brackets and suggests "a better option".

My point about the joint design and friction at the head/trunnion and L brackets is being heavily misunderstood.

Short form; A lubricated ball end or pivoting joint with sliding surfaces will absolutely NOT have more friction than a bare metal to metal flat surface.

So basically, some of you are fiercely debating the amount of friction of a lubricated joint vs dry joint. Wow. I give up. You win.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2014 11:02 AM

2011 Flagstaff 831FKBSS

Equalizer E4 1200/12000

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2014 09:41 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2014 09:28 AM

Keep in mind there are just as many pounds of force pushing on the pivot as on the L-bracket. The pivot area is much more than only a pivot.

2016 Silverado 3500HD DRW D/A 4x4

2018 Keystone Cougar 26RBS

2006 Weekend Warrior FK1900

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dec-29-2014 08:16 AM

RinconVTR wrote:My Equal-i-zer hitch would disagree with you whole heartedly. The L brackets definitely play the big role in weight distribution, but very little in sway control. All the wear on mine is where the bars pivot in the hitch head. And I routinely lube it too.

The L brackets is where the major friction and sway resistance is occurring on these two WHD's, not the trunnion knuckle/ball end. Period.

2022 Grand Design Imagine XLS 22RBE